Testing

To test operation of water inlet valve, place the leads of a volt meter across the termina{s of the solenoid in any fill phase of the operating cycle where the water inlet valve should be energized If the meter indicates tine voltage, water should flow into the tub If water does not flow into the tub, either the water inlet valve is defective or the water supply is inadequate Make certain the hot water faucet is fully on If the water supply is not at fault, the water inlet valve is defective

C Sen/zcing

To Clean Operating Parts of the Vaive:

!Remove valve bracket from tub or installation module

2Remove 4 screws holding solenoid, valve body and bracket together

3Remove the plunger housing, spring and plunger

4Check the parts for defects, dirt particles or for formation of lime

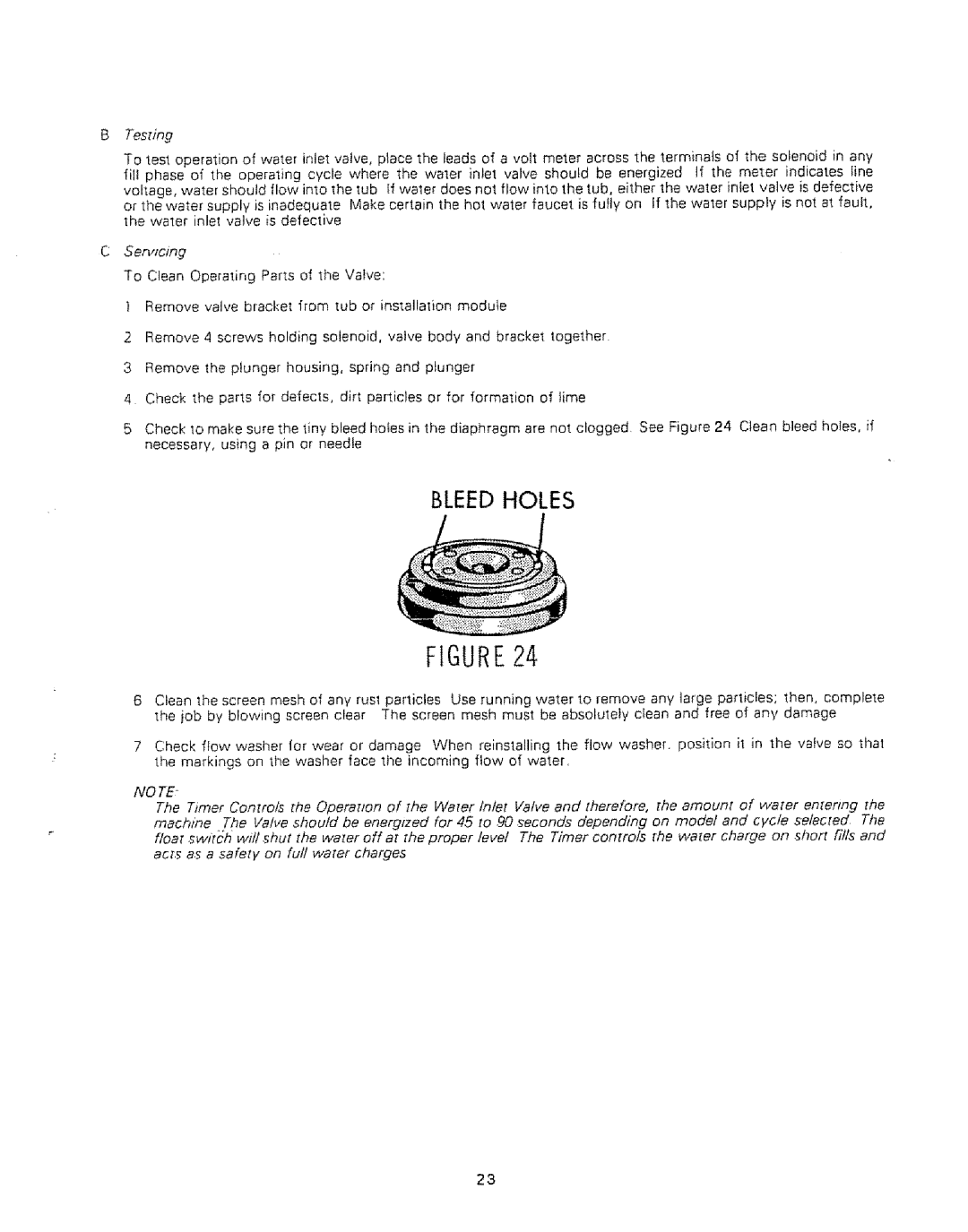

5Check 1o make sure the tiny bleed hoies in the diaphragm are not clogged See Figure 24 Clean bleed holes, if necessary, using a pin or needte

BLEED HOLES

FIGURE24

6 Clean the screen mesh of any rust particles Use running water to remove any large particles; then, complete the iob by blowing screen clear The screen mesh must be absolutely clean and free of any damage

7 Check flow washer for wear or damage When reinstalling the flow washer, position i1 in the valve so that the markings on the washer face the incoming flow of "water.

NOTE

The Timer Controls the Operazton of the Water Inlet Valve and therefore, the amount of water emenng the machine The Valve should be energzzed for 45 to .90 ._econds depending on model and cycle selected The float switch will .shut the water off at the proper level The Timer controls the wa[er charge on short fills and acts as a safety on full water charges

23