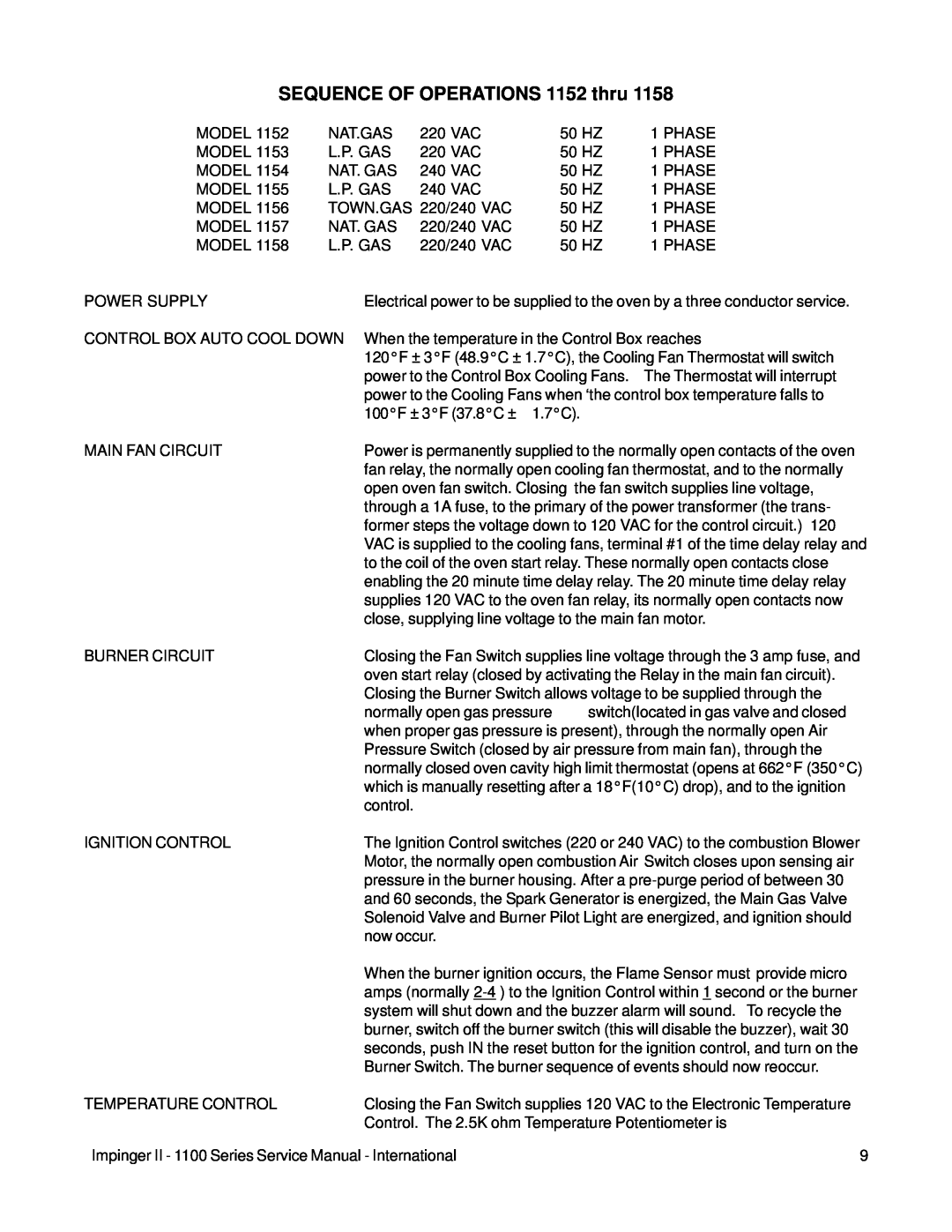

SEQUENCE OF OPERATIONS 1152 thru 1158

MODEL 1152 | NAT.GAS | 220 VAC | 50 HZ | 1 PHASE |

MODEL 1153 | L.P. GAS | 220 VAC | 50 HZ | 1 PHASE |

MODEL 1154 | NAT. GAS | 240 VAC | 50 HZ | 1 PHASE |

MODEL 1155 | L.P. GAS | 240 VAC | 50 HZ | 1 PHASE |

MODEL 1156 | TOWN.GAS 220/240 VAC | 50 HZ | 1 PHASE | |

MODEL 1157 | NAT. GAS | 220/240 VAC | 50 HZ | 1 PHASE |

MODEL 1158 | L.P. GAS | 220/240 VAC | 50 HZ | 1 PHASE |

POWER SUPPLY | Electrical power to be supplied to the oven by a three conductor service. | |

CONTROL BOX AUTO COOL DOWN | When the temperature in the Control Box reaches | |

| 120°F ± 3°F (48.9°C ± 1.7°C), the Cooling Fan Thermostat will switch | |

| power to the Control Box Cooling Fans. The Thermostat will interrupt | |

| power to the Cooling Fans when ‘the control box temperature falls to | |

| 100°F ± 3°F (37.8°C ± 1.7°C). |

|

MAIN FAN CIRCUIT | Power is permanently supplied to the normally open contacts of the oven | |

| fan relay, the normally open cooling fan thermostat, and to the normally | |

| open oven fan switch. Closing the fan switch supplies line voltage, | |

| through a 1A fuse, to the primary of the power transformer (the trans- | |

| former steps the voltage down to 120 VAC for the control circuit.) 120 | |

| VAC is supplied to the cooling fans, terminal #1 of the time delay relay and | |

| to the coil of the oven start relay. These normally open contacts close | |

| enabling the 20 minute time delay relay. The 20 minute time delay relay | |

| supplies 120 VAC to the oven fan relay, its normally open contacts now | |

| close, supplying line voltage to the main fan motor. | |

BURNER CIRCUIT | Closing the Fan Switch supplies line voltage through the 3 amp fuse, and | |

| oven start relay (closed by activating the Relay in the main fan circuit). | |

| Closing the Burner Switch allows voltage to be supplied through the | |

| normally open gas pressure | switch(located in gas valve and closed |

| when proper gas pressure is present), through the normally open Air | |

| Pressure Switch (closed by air pressure from main fan), through the | |

| normally closed oven cavity high limit thermostat (opens at 662°F (350°C) | |

| which is manually resetting after a 18°F(10°C) drop), and to the ignition | |

| control. |

|

IGNITION CONTROL | The Ignition Control switches (220 or 240 VAC) to the combustion Blower | |

| Motor, the normally open combustion Air Switch closes upon sensing air | |

| pressure in the burner housing. After a | |

| and 60 seconds, the Spark Generator is energized, the Main Gas Valve | |

| Solenoid Valve and Burner Pilot Light are energized, and ignition should | |

| now occur. |

|

| When the burner ignition occurs, the Flame Sensor must provide micro | |

| amps (normally | |

| system will shut down and the buzzer alarm will sound. To recycle the | |

| burner, switch off the burner switch (this will disable the buzzer), wait 30 | |

| seconds, push IN the reset button for the ignition control, and turn on the | |

| Burner Switch. The burner sequence of events should now reoccur. | |

TEMPERATURE CONTROL | Closing the Fan Switch supplies 120 VAC to the Electronic Temperature | |

| Control. The 2.5K ohm Temperature Potentiometer is | |

Impinger II - 1100 Series Service Manual - International | 9 | |