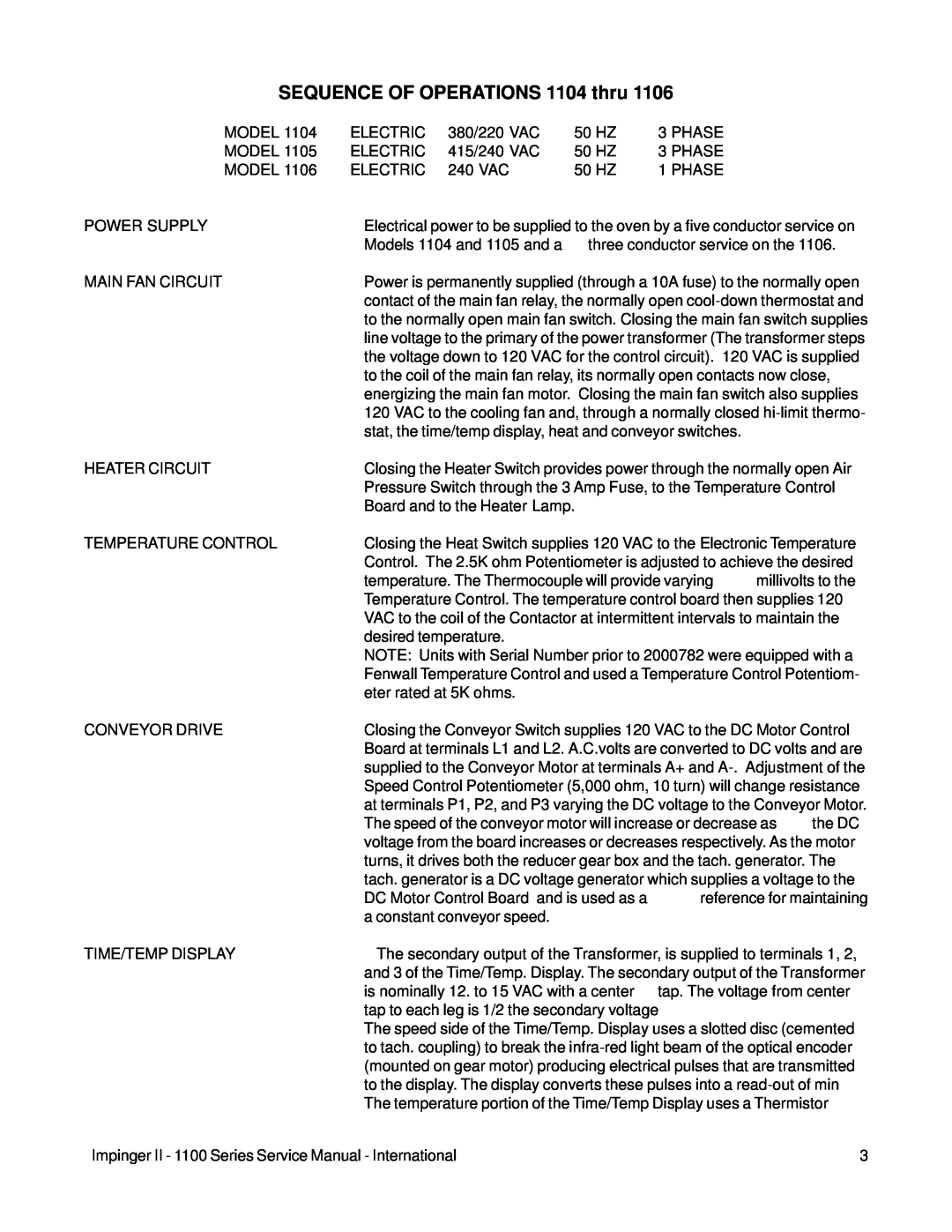

SEQUENCE OF OPERATIONS 1104 thru 1106

MODEL 1104 | ELECTRIC | 380/220 VAC | 50 HZ | 3 PHASE |

MODEL 1105 | ELECTRIC | 415/240 VAC | 50 HZ | 3 PHASE |

MODEL 1106 | ELECTRIC | 240 VAC | 50 HZ | 1 PHASE |

POWER SUPPLY | Electrical power to be supplied to the oven by a five conductor service on | |||

| Models 1104 and 1105 and a three conductor service on the 1106. | |||

MAIN FAN CIRCUIT | Power is permanently supplied (through a 10A fuse) to the normally open | |||

| contact of the main fan relay, the normally open | |||

| to the normally open main fan switch. Closing the main fan switch supplies | |||

| line voltage to the primary of the power transformer (The transformer steps | |||

| the voltage down to 120 VAC for the control circuit). 120 VAC is supplied | |||

| to the coil of the main fan relay, its normally open contacts now close, | |||

| energizing the main fan motor. Closing the main fan switch also supplies | |||

| 120 VAC to the cooling fan and, through a normally closed | |||

| stat, the time/temp display, heat and conveyor switches. |

|

| |

HEATER CIRCUIT | Closing the Heater Switch provides power through the normally open Air | |||

| Pressure Switch through the 3 Amp Fuse, to the Temperature Control | |||

| Board and to the Heater Lamp. |

|

|

|

TEMPERATURE CONTROL | Closing the Heat Switch supplies 120 VAC to the Electronic Temperature | |||

| Control. The 2.5K ohm Potentiometer is adjusted to achieve the desired | |||

| temperature. The Thermocouple will provide varying | millivolts to the | ||

| Temperature Control. The temperature control board then supplies 120 | |||

| VAC to the coil of the Contactor at intermittent intervals to maintain the | |||

| desired temperature. |

|

|

|

| NOTE: Units with Serial Number prior to 2000782 were equipped with a | |||

| Fenwall Temperature Control and used a Temperature Control Potentiom- | |||

| eter rated at 5K ohms. |

|

|

|

CONVEYOR DRIVE | Closing the Conveyor Switch supplies 120 VAC to the DC Motor Control | |||

| Board at terminals L1 and L2. A.C.volts are converted to DC volts and are | |||

| supplied to the Conveyor Motor at terminals A+ and | |||

| Speed Control Potentiometer (5,000 ohm, 10 turn) will change resistance | |||

| at terminals P1, P2, and P3 varying the DC voltage to the Conveyor Motor. | |||

| The speed of the conveyor motor will increase or decrease as | the DC | ||

| voltage from the board increases or decreases respectively. As the motor | |||

| turns, it drives both the reducer gear box and the tach. generator. The | |||

| tach. generator is a DC voltage generator which supplies a voltage to the | |||

| DC Motor Control Board and is used as a | reference for maintaining | ||

| a constant conveyor speed. |

|

|

|

TIME/TEMP DISPLAY | The secondary output of the Transformer, is supplied to terminals 1, 2, | |||

| and 3 of the Time/Temp. Display. The secondary output of the Transformer | |||

| is nominally 12. to 15 VAC with a center | tap. The voltage from center | ||

| tap to each leg is 1/2 the secondary voltage |

|

| |

| The speed side of the Time/Temp. Display uses a slotted disc (cemented | |||

| to tach. coupling) to break the | |||

| (mounted on gear motor) producing electrical pulses that are transmitted | |||

| to the display. The display converts these pulses into a | |||

| The temperature portion of the Time/Temp Display uses a Thermistor | |||

Impinger II - 1100 Series Service Manual - International | 3 |