OPERATION | ||

|

Return to Section TOC

Return to Section TOC

Section TOC

Return to Master TOC

Return to Master TOC

Master TOC

120V Receptacle Operation:

•Set the Output Control on the

•Maximum material thickness that can be cut is 1/4".

240V Receptacle Operation:

•The

•Maximum material thickness that can be cut is 3/8".

AUXILIARY POWER OPERATION

![]() WARNING

WARNING

Be sure that any electrical equipment plugged into the generator AC power receptacles can withstand a ±10% voltage and a ±5% frequency variation. Some elec- tronic devices cannot be powered by the OUTBACK®

185Refer to Table A.2, ELECTRICAL DEVICE USE WITH THE OUTBACK® 185, in the INSTALLATION section of this manual.

GENERAL INFORMATION

The OUTBACK® 185 is rated at 5700 Peak watts or 5200 continuous watts. It provides both 120 volt and 240 volt power. You can draw up to 20 amps from either side of the 120 volt duplex receptacle, but not more than 35.4 amps from both sides at once. Up to

17.7amps can be drawn from the single 240 volt receptacle.

Electrical loads in watts are calculated by multiplying the voltage rating of the load by the number of amps it draws. (This information is given on the load device nameplate.) For example, a device rated 120 volts, 2 amps will need 240 watts of power (120 x 2 = 240).

You can use Table B.3, AUXILIARY POWER APPLI- CATIONS, to determine the wattage requirements of the most common types of loads you can power with the OUTBACK® 185 Be sure to read the notes at the bottom of the table.

TO USE THE OUTBACK® 185 AS AN AUXILIARY POWER SUPPLY:

1.Start the gasoline engine. See ENGINE OPERA- TION in this section of the manual.

2.Set the current control dial on the output control panel to “MAX.” See Figure B.1.

3.Plug the load(s) into the appropriate 120 volt or 240 volt power receptacle.

NOTE: During welding, the maximum generator out- put for auxiliary loads is 100 watts.

NOTE: You can supply multiple loads as long as the total load does not exceed 5700 Peak watts or 5200 continuous watts. Be sure to start the largest loads first.

Return to

Return to Section TOC

Return to

Return to Master TOC

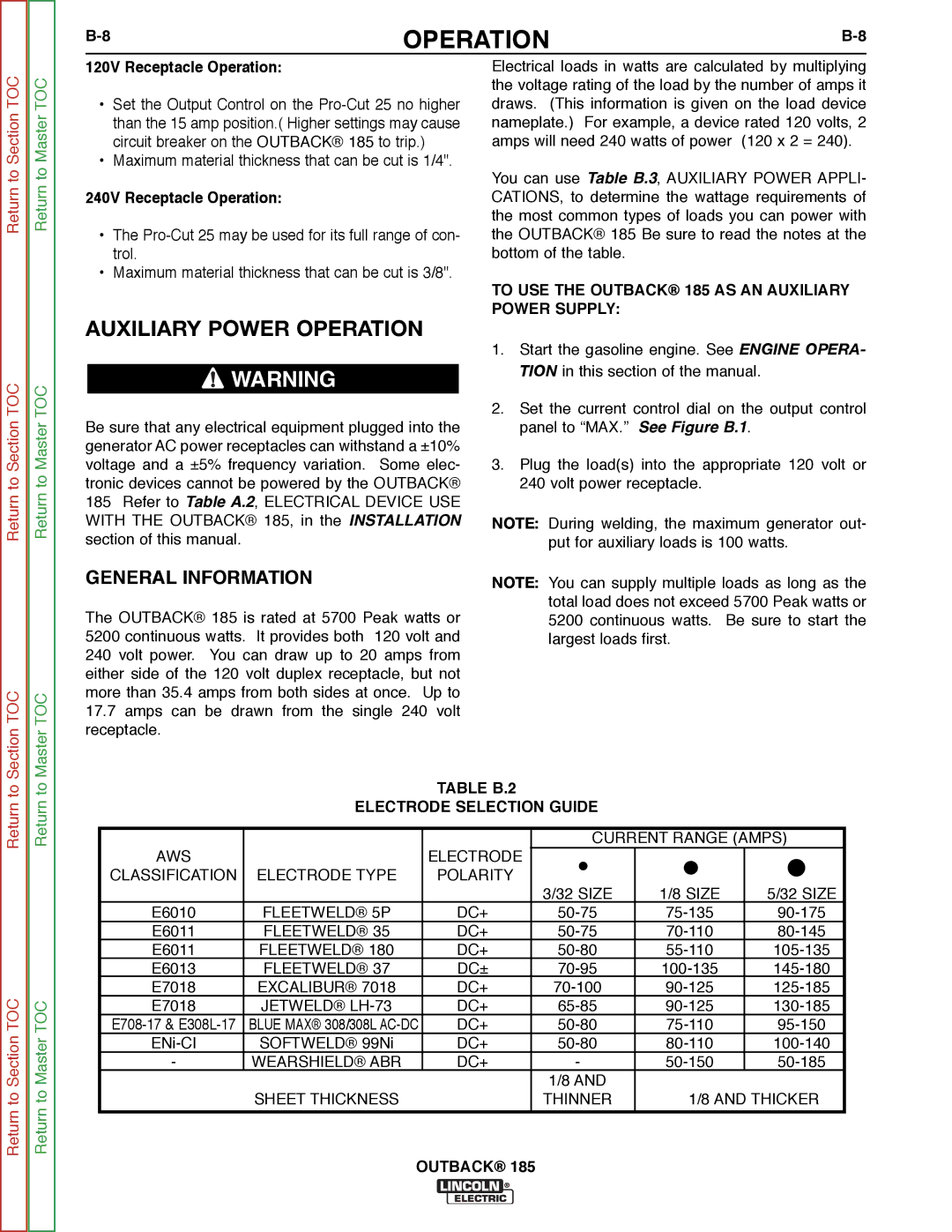

TABLE B.2

ELECTRODE SELECTION GUIDE

|

|

| CURRENT RANGE (AMPS) | ||

AWS |

| ELECTRODE |

|

|

|

CLASSIFICATION | ELECTRODE TYPE | POLARITY |

|

|

|

|

|

| 3/32 SIZE | 1/8 SIZE | 5/32 SIZE |

E6010 | FLEETWELD® 5P | DC+ | |||

E6011 | FLEETWELD® 35 | DC+ | |||

E6011 | FLEETWELD® 180 | DC+ | |||

E6013 | FLEETWELD® 37 | DC± | |||

E7018 | EXCALIBUR® 7018 | DC+ | |||

E7018 | JETWELD® | DC+ | |||

BLUE MAX® 308/308L | DC+ | ||||

SOFTWELD® 99Ni | DC+ | ||||

- | WEARSHIELD® ABR | DC+ | - | ||

|

|

| 1/8 AND |

|

|

| SHEET THICKNESS |

| THINNER | 1/8 AND THICKER | |

|

|

|

|

|

|

OUTBACK® 185