Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING AND REPAIR | ||

|

WELD BOOST SYSTEM TEST (continued)

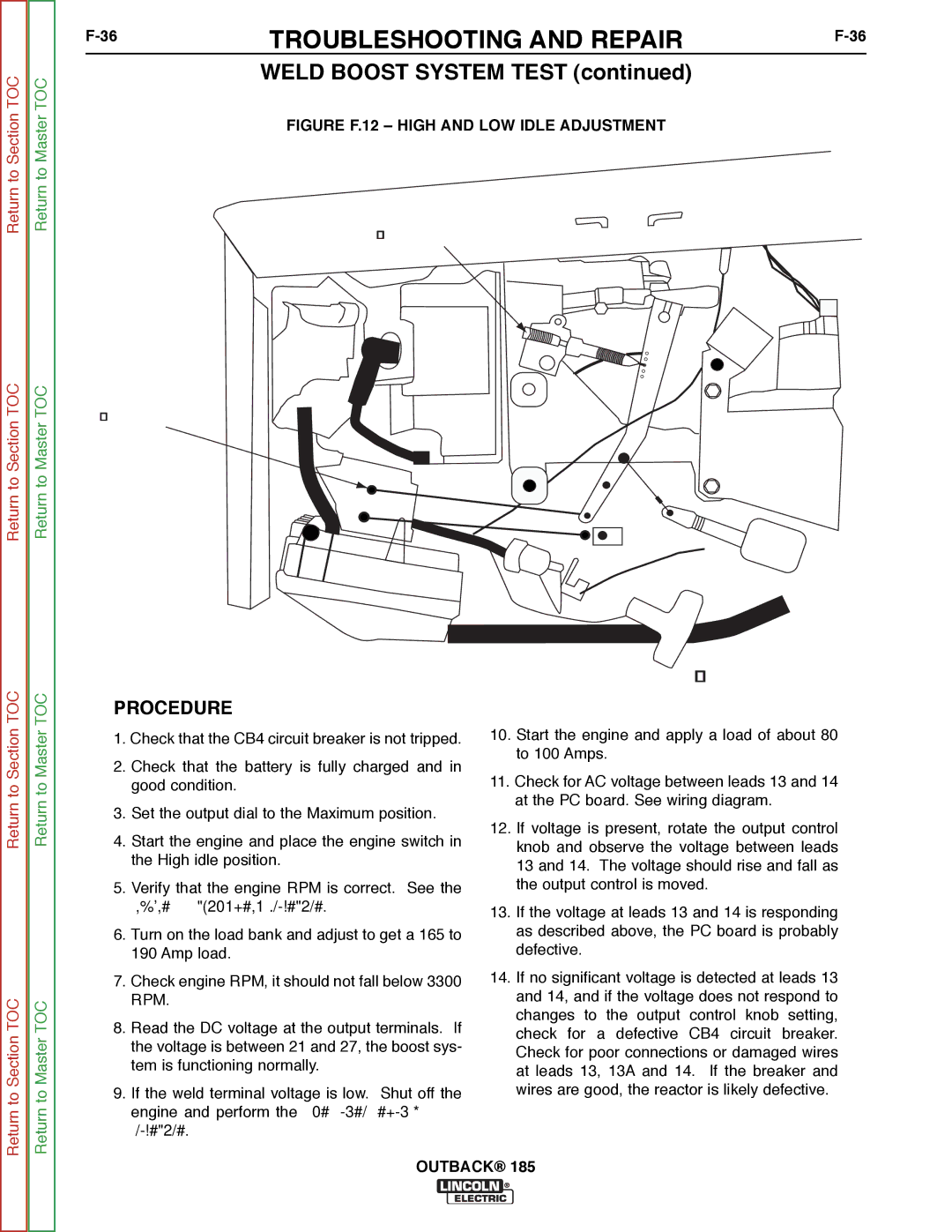

FIGURE F.12 – HIGH AND LOW IDLE ADJUSTMENT

HIGH IDLE ADJUSTMENT

LOW IDLE ADJUSTMENT

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

PROCEDURE

1.Check that the CB4 circuit breaker is not tripped.

2.Check that the battery is fully charged and in good condition.

3.Set the output dial to the Maximum position.

4.Start the engine and place the engine switch in the High idle position.

5.Verify that the engine RPM is correct. See the Engine RPM adjustment procedure.

6.Turn on the load bank and adjust to get a 165 to 190 Amp load.

7.Check engine RPM, it should not fall below 3300 RPM.

8.Read the DC voltage at the output terminals. If the voltage is between 21 and 27, the boost sys- tem is functioning normally.

9.If the weld terminal voltage is low. Shut off the engine and perform the Case Cover Removal Procedure.

TOP VIEW OF ENGINE

10.Start the engine and apply a load of about 80 to 100 Amps.

11.Check for AC voltage between leads 13 and 14 at the PC board. See wiring diagram.

12.If voltage is present, rotate the output control knob and observe the voltage between leads 13 and 14. The voltage should rise and fall as the output control is moved.

13.If the voltage at leads 13 and 14 is responding as described above, the PC board is probably defective.

14.If no significant voltage is detected at leads 13 and 14, and if the voltage does not respond to changes to the output control knob setting, check for a defective CB4 circuit breaker. Check for poor connections or damaged wires at leads 13, 13A and 14. If the breaker and wires are good, the reactor is likely defective.