Return to Section TOC

Return to Master TOC

TROUBLESHOOTING AND REPAIR | ||

|

ROTOR FLASHING AND VOLTAGE TEST (continued)

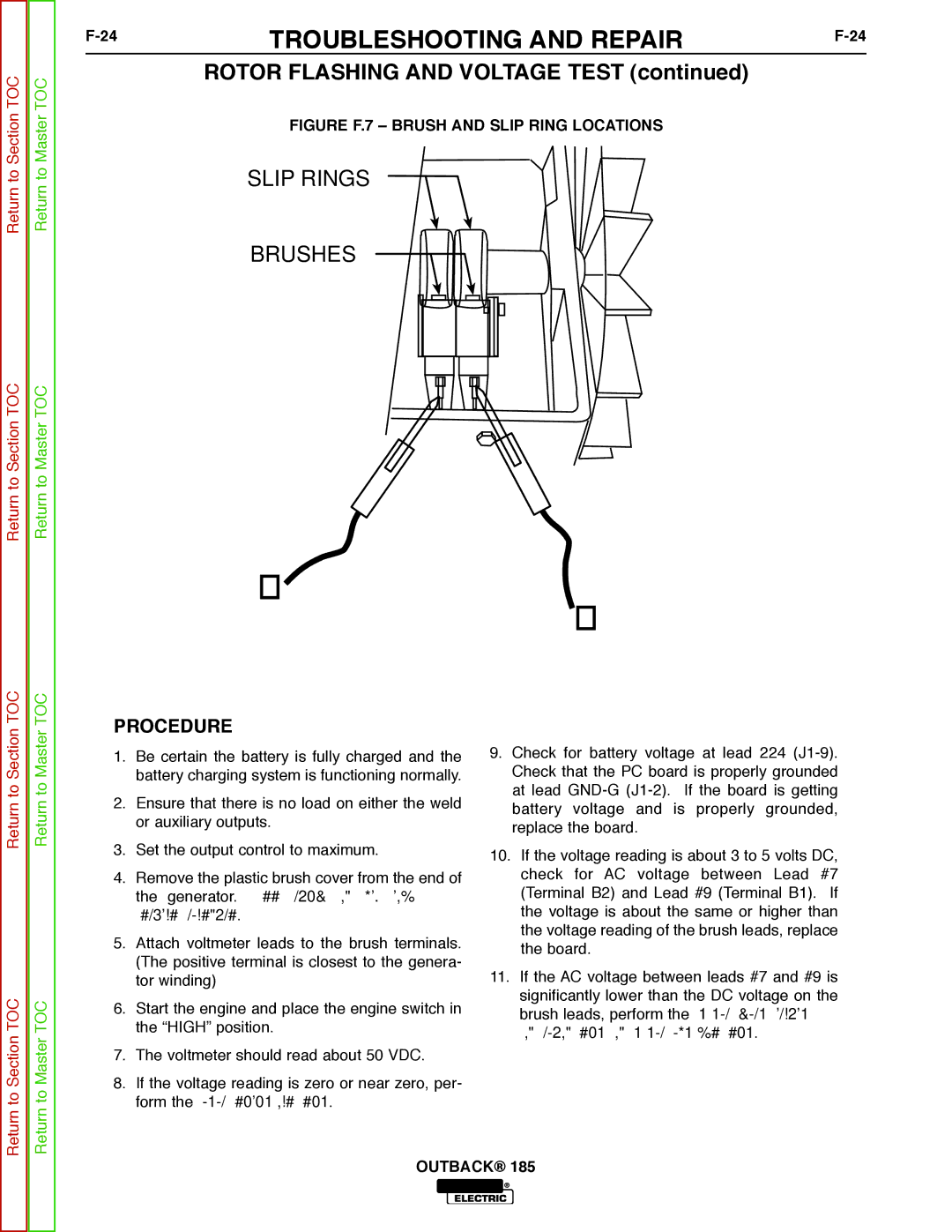

FIGURE F.7 – BRUSH AND SLIP RING LOCATIONS

SLIP RINGS

BRUSHES

Return to Section TOC

Return to Master TOC

+ -

-

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

PROCEDURE

1.Be certain the battery is fully charged and the battery charging system is functioning normally.

2.Ensure that there is no load on either the weld or auxiliary outputs.

3.Set the output control to maximum.

4.Remove the plastic brush cover from the end of the generator. See Brush and Slip Ring Service Procedure.

5.Attach voltmeter leads to the brush terminals. (The positive terminal is closest to the genera- tor winding)

6.Start the engine and place the engine switch in the “HIGH” position.

7.The voltmeter should read about 50 VDC.

8.If the voltage reading is zero or near zero, per- form the Rotor Resistance Test.

9.Check for battery voltage at lead 224

10.If the voltage reading is about 3 to 5 volts DC, check for AC voltage between Lead #7 (Terminal B2) and Lead #9 (Terminal B1). If the voltage is about the same or higher than the voltage reading of the brush leads, replace the board.

11.If the AC voltage between leads #7 and #9 is significantly lower than the DC voltage on the brush leads, perform the Stator Short Circuit and Ground Test and Stator Voltage Test.