Return to Section TOC

to Section TOC

Return to Master TOC

to Master TOC

OPERATION | ||

|

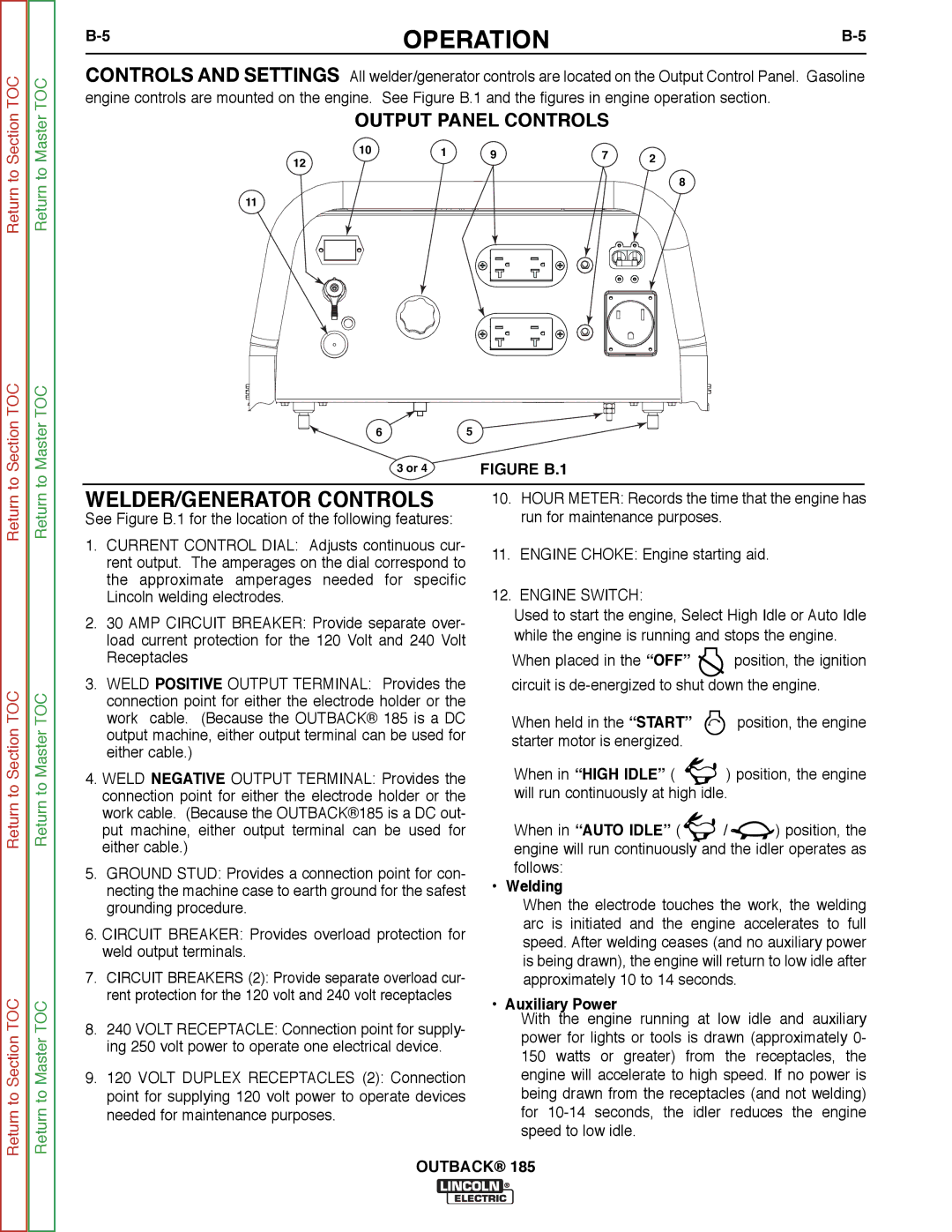

CONTROLS AND SETTINGS All welder/generator controls are located on the Output Control Panel. Gasoline engine controls are mounted on the engine. See Figure B.1 and the figures in engine operation section.

OUTPUT PANEL CONTROLS

10 | 1 | 9 | 7 | 2 |

12 |

|

8

11

65

3 or 4 | FIGURE B.1 |

Return

Return to Section TOC

Return to Section TOC

Return

Return to Master TOC

Return to Master TOC

WELDER/GENERATOR CONTROLS

See Figure B.1 for the location of the following features:

1.CURRENT CONTROL DIAL: Adjusts continuous cur- rent output. The amperages on the dial correspond to the approximate amperages needed for specific Lincoln welding electrodes.

2.30 AMP CIRCUIT BREAKER: Provide separate over- load current protection for the 120 Volt and 240 Volt Receptacles

3.WELD POSITIVE OUTPUT TERMINAL: Provides the connection point for either the electrode holder or the work cable. (Because the OUTBACK® 185 is a DC output machine, either output terminal can be used for either cable.)

4.WELD NEGATIVE OUTPUT TERMINAL: Provides the connection point for either the electrode holder or the work cable. (Because the OUTBACK®185 is a DC out- put machine, either output terminal can be used for either cable.)

5.GROUND STUD: Provides a connection point for con- necting the machine case to earth ground for the safest grounding procedure.

6.CIRCUIT BREAKER: Provides overload protection for weld output terminals.

7.CIRCUIT BREAKERS (2): Provide separate overload cur- rent protection for the 120 volt and 240 volt receptacles

8.240 VOLT RECEPTACLE: Connection point for supply- ing 250 volt power to operate one electrical device.

9.120 VOLT DUPLEX RECEPTACLES (2): Connection point for supplying 120 volt power to operate devices needed for maintenance purposes.

10.HOUR METER: Records the time that the engine has run for maintenance purposes.

11.ENGINE CHOKE: Engine starting aid.

12.ENGINE SWITCH:

Used to start the engine, Select High Idle or Auto Idle while the engine is running and stops the engine.

When placed in the “OFF” ![]() position, the ignition circuit is

position, the ignition circuit is

When held in the “START” ![]() position, the engine starter motor is energized.

position, the engine starter motor is energized.

When in “HIGH IDLE” ( ![]() ) position, the engine will run continuously at high idle.

) position, the engine will run continuously at high idle.

| When in “AUTO IDLE” ( | / | ) position, the |

| engine will run continuously and the idler operates as | ||

| follows: |

|

|

• | Welding |

|

|

| When the electrode touches the work, the welding | ||

| arc is initiated and the engine accelerates to full | ||

| speed. After welding ceases (and no auxiliary power | ||

| is being drawn), the engine will return to low idle after | ||

| approximately 10 to 14 seconds. |

| |

• | Auxiliary Power |

|

|

| With the engine running | at low | idle and auxiliary |

power for lights or tools is drawn (approximately 0- 150 watts or greater) from the receptacles, the engine will accelerate to high speed. If no power is being drawn from the receptacles (and not welding) for

OUTBACK® 185