Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

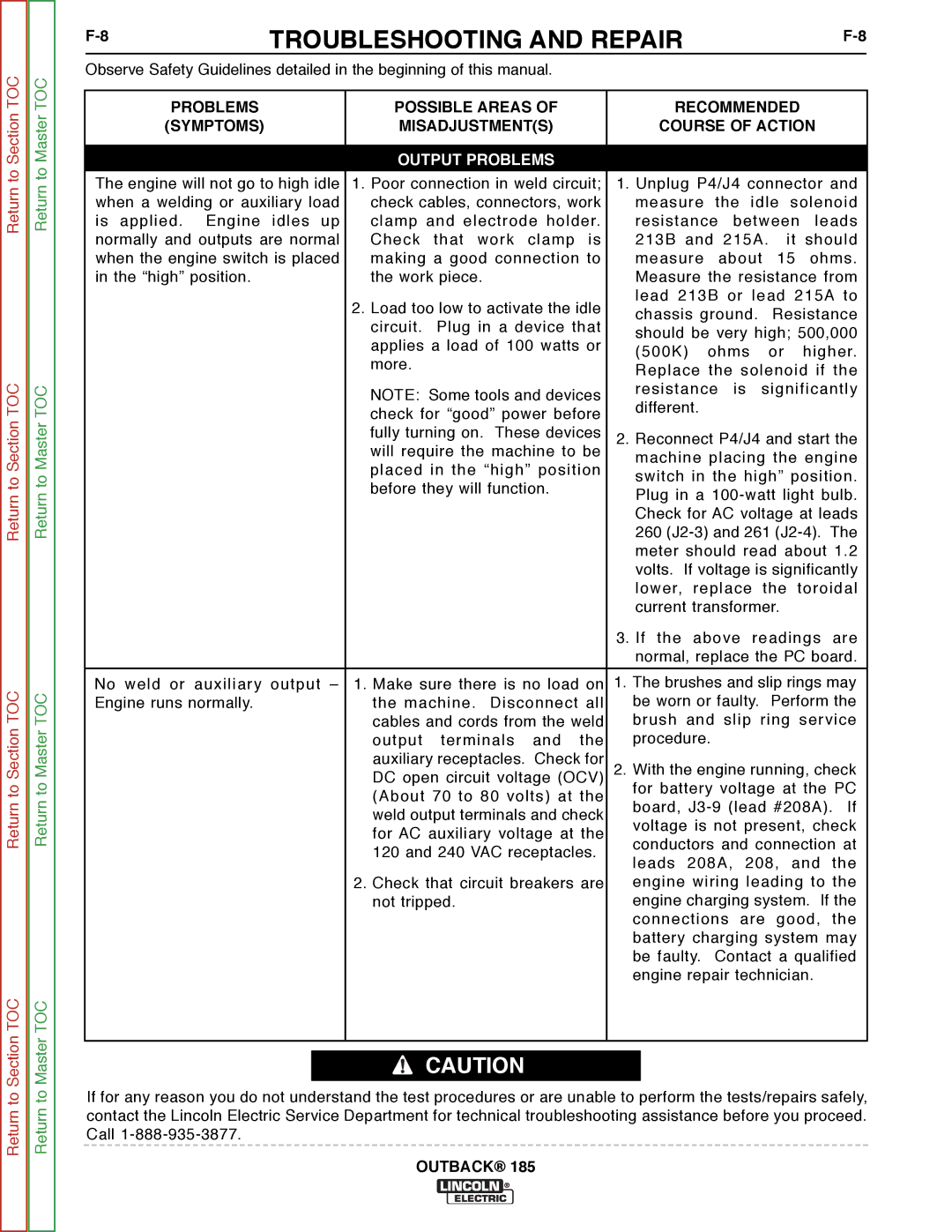

TROUBLESHOOTING AND REPAIR | ||

|

Observe Safety Guidelines detailed in the beginning of this manual.

PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED |

| |||||

(SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION | ||||||

|

|

|

|

|

|

|

| |

| OUTPUT PROBLEMS |

|

|

|

|

|

| |

The engine will not go to high idle | 1. Poor connection in weld circuit; | 1. Unplug P4/J4 connector and | ||||||

when a welding or auxiliary load | check cables, connectors, work | measure | the idle | solenoid | ||||

is applied. Engine idles up | clamp and electrode holder. | resistance | between | leads | ||||

normally and outputs are normal | Check that work clamp is | 213B and | 215A. | it | should | |||

when the engine switch is placed | making a good connection to | measure about 15 ohms. | ||||||

in the “high” position. | the work piece. | Measure the resistance from | ||||||

| 2. Load too low to activate the idle | lead 213B or lead 215A to | ||||||

| chassis ground. | Resistance | ||||||

| circuit. | Plug in a device that | ||||||

| should be very high; 500,000 | |||||||

| applies a load of 100 watts or | |||||||

| (500K) | ohms | or |

| higher. | |||

| more. |

|

| |||||

|

| Replace the solenoid if the | ||||||

|

|

| ||||||

| NOTE: Some tools and devices | resistance | is | significantly | ||||

| different. |

|

|

|

|

| ||

| check for “good” power before |

|

|

|

|

| ||

|

|

|

|

|

|

| ||

| fully turning on. These devices | 2. Reconnect P4/J4 and start the | ||||||

| will require the machine to be | machine placing the engine | ||||||

| placed in the “high” position | |||||||

| switch in the high” position. | |||||||

| before they will function. | |||||||

| Plug in a | |||||||

|

|

| ||||||

|

|

| Check for AC voltage at leads | |||||

|

|

| 260 | |||||

|

|

| meter should read about 1.2 | |||||

|

|

| volts. If voltage is significantly | |||||

|

|

| lower, replace | the | toroidal | |||

|

|

| current transformer. |

|

| |||

|

|

| 3. If the above readings are | |||||

|

|

| normal, replace the PC board. | |||||

|

|

| ||||||

No weld or auxiliary output – | 1. Make sure there is no load on | 1. The brushes and slip rings may | ||||||

Engine runs normally. | the machine. Disconnect all | be worn or faulty. Perform the | ||||||

| cables and cords from the weld | brush and slip ring service | ||||||

| output | terminals and the | procedure. |

|

|

|

| |

| auxiliary receptacles. Check for | 2. With the engine running, check | ||||||

| DC open circuit voltage (OCV) | |||||||

| (About 70 to 80 volts) at the | for battery voltage at the PC | ||||||

| board, | |||||||

| weld output terminals and check | |||||||

| voltage is not present, check | |||||||

| for AC auxiliary voltage at the | |||||||

| conductors and connection at | |||||||

| 120 and 240 VAC receptacles. | |||||||

| leads 208A, 208, and the | |||||||

|

|

| ||||||

| 2. Check that circuit breakers are | engine wiring leading to the | ||||||

| not tripped. | engine charging system. If the | ||||||

|

|

| connections are good, the | |||||

|

|

| battery charging system may | |||||

|

|

| be faulty. Contact a qualified | |||||

|

|

| engine repair technician. | |||||

|

|

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call