Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING AND REPAIR | ||

|

ROTOR REMOVAL AND REPLACEMENT PROCEDURE (continued)

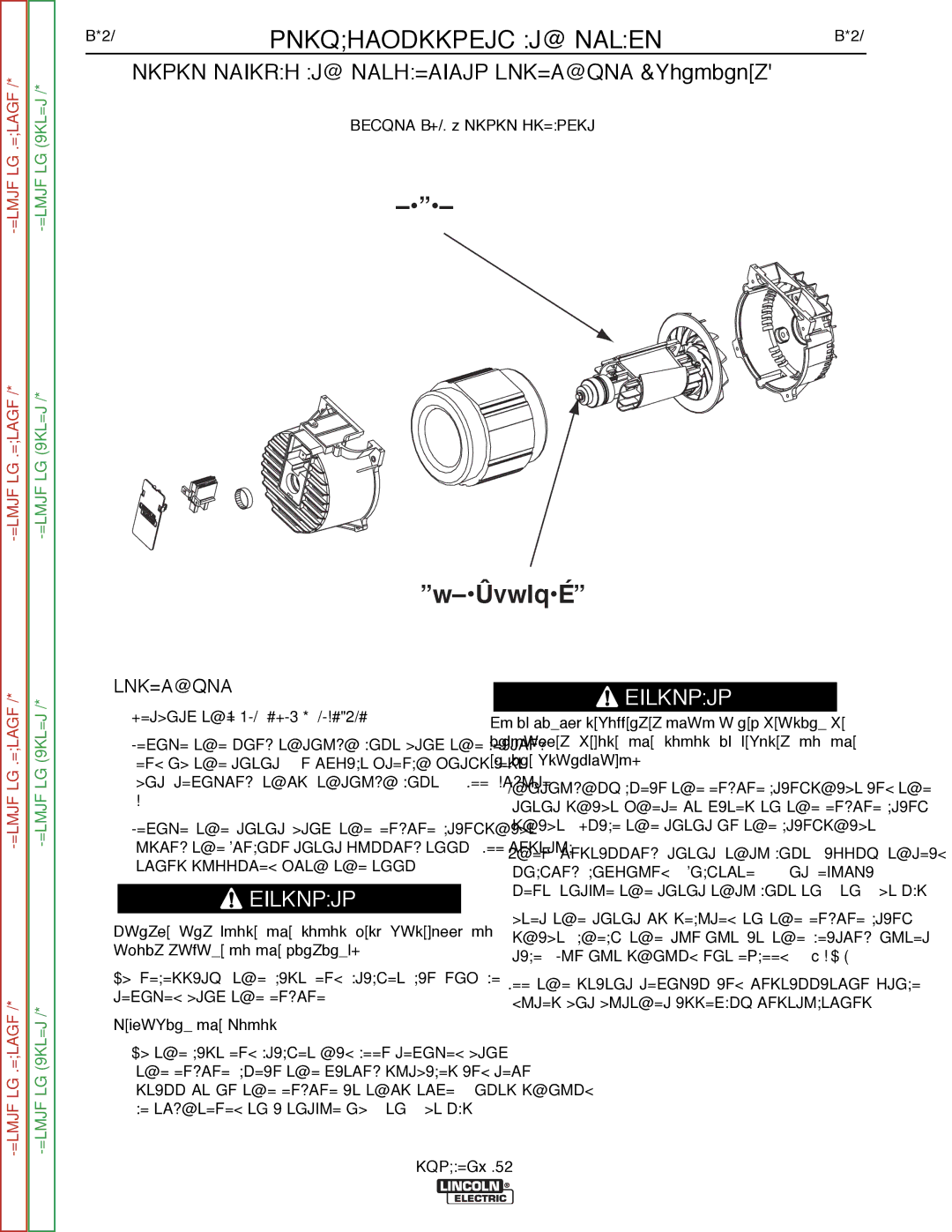

FIGURE F.21 – ROTOR LOCATION

ROTOR

THROUGH BOLT

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

PROCEDURE

1.Perform the Stator Removal Procedure.

2.Remove the long

3.Remove the rotor from the engine crankshaft using the Lincoln

![]() IMPORTANT

IMPORTANT

Handle and store the rotor very carefully to avoid damage to the windings.

If necessary, the cast end bracket can now be removed from the engine.

Replacing the Rotor

1.If the cast end bracket had been removed from the engine, clean the mating surfaces and rein- stall it on the engine at this time. Bolts should be tightened to a torque of 22 to 24

![]() IMPORTANT

IMPORTANT

It is highly recommended that a new bearing be installed before the rotor is secured to the engine crankshaft.

2.Thoroughly clean the engine crankshaft and the rotor shaft where it mates to the engine crank- shaft. Place the rotor on the crankshaft.

3.When installing rotor

4.After the rotor is secured to the engine crank- shaft, check the

5.See the stator removal and installation proce- dures for further assembly instructions.