Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING AND REPAIR | ||

|

ROTOR RESISTANCE AND GROUND TEST (DYNAMIC) (continued)

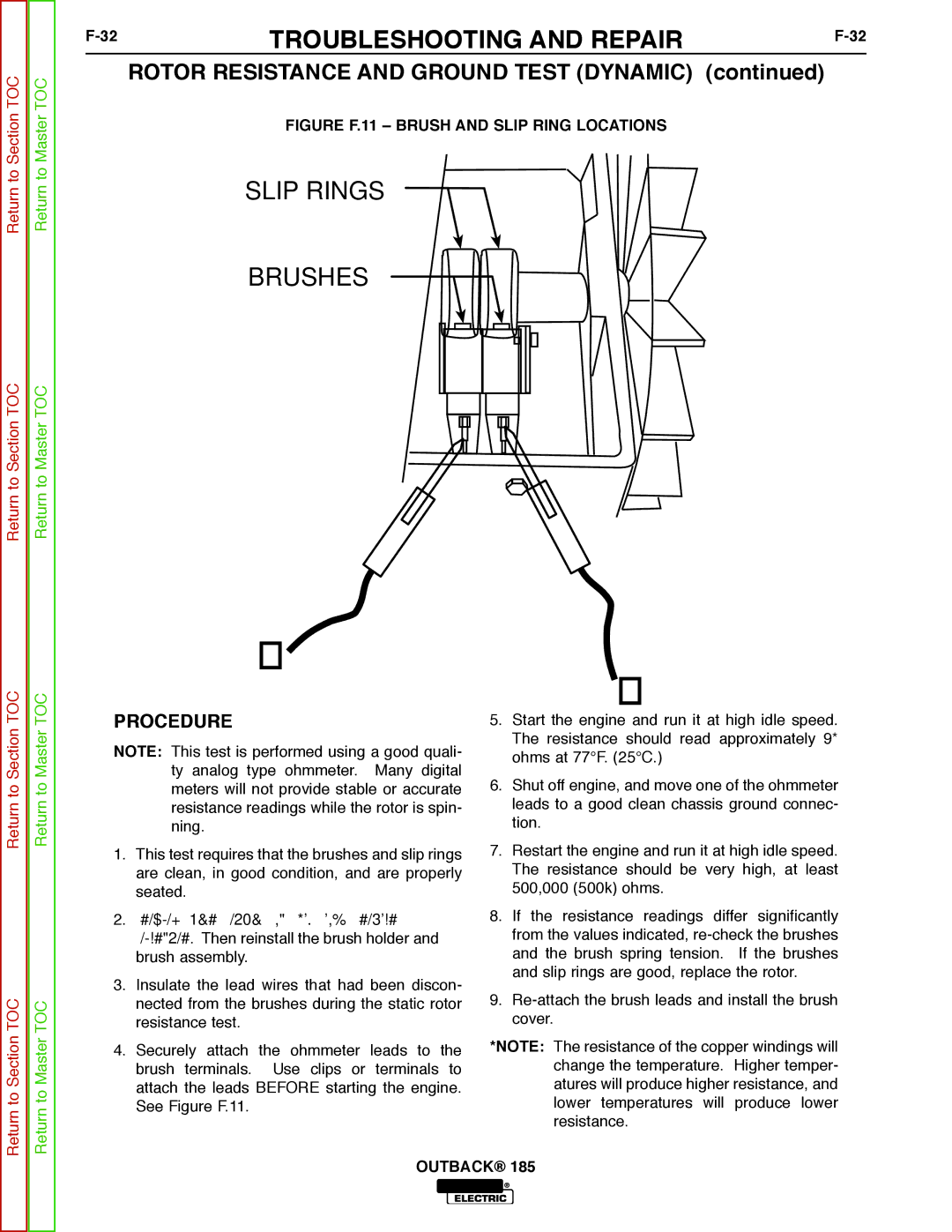

FIGURE F.11 – BRUSH AND SLIP RING LOCATIONS

SLIP RINGS

BRUSHES

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

+

PROCEDURE

NOTE: This test is performed using a good quali- ty analog type ohmmeter. Many digital meters will not provide stable or accurate resistance readings while the rotor is spin- ning.

1.This test requires that the brushes and slip rings are clean, in good condition, and are properly seated.

2.Perform the Brush and Slip Ring Service Procedure. Then reinstall the brush holder and brush assembly.

3.Insulate the lead wires that had been discon- nected from the brushes during the static rotor resistance test.

4.Securely attach the ohmmeter leads to the brush terminals. Use clips or terminals to attach the leads BEFORE starting the engine. See Figure F.11.

![]() -

-

5.Start the engine and run it at high idle speed. The resistance should read approximately 9* ohms at 77°F. (25°C.)

6.Shut off engine, and move one of the ohmmeter leads to a good clean chassis ground connec- tion.

7.Restart the engine and run it at high idle speed. The resistance should be very high, at least 500,000 (500k) ohms.

8.If the resistance readings differ significantly from the values indicated,

9.

*NOTE: The resistance of the copper windings will change the temperature. Higher temper- atures will produce higher resistance, and lower temperatures will produce lower resistance.