|

| INSTALLATION | ||||

|

|

|

| |||

TOC | TOC | CONNECT OUTPUT COMPONENTS | GUN LINER AND CONTACT | TIP | ||

|

| INSTALLATION |

| |||

Section | Master | INSTALL THE WORK CLAMP |

| |||

|

| |||||

|

|

|

| |||

|

|

|

| The Magnum 250L gun and cable provided with the | ||

to | to | Attach the work clamp to the cable which extends from | ||||

the front of the machine using the following procedure: | ||||||

Return | Return | |||||

|

| .035” (0.9mm) contact tip. |

| |||

|

|

|

|

| ||

|

| 1. Insert the lug on the end of the work cable through |

|

| ||

|

|

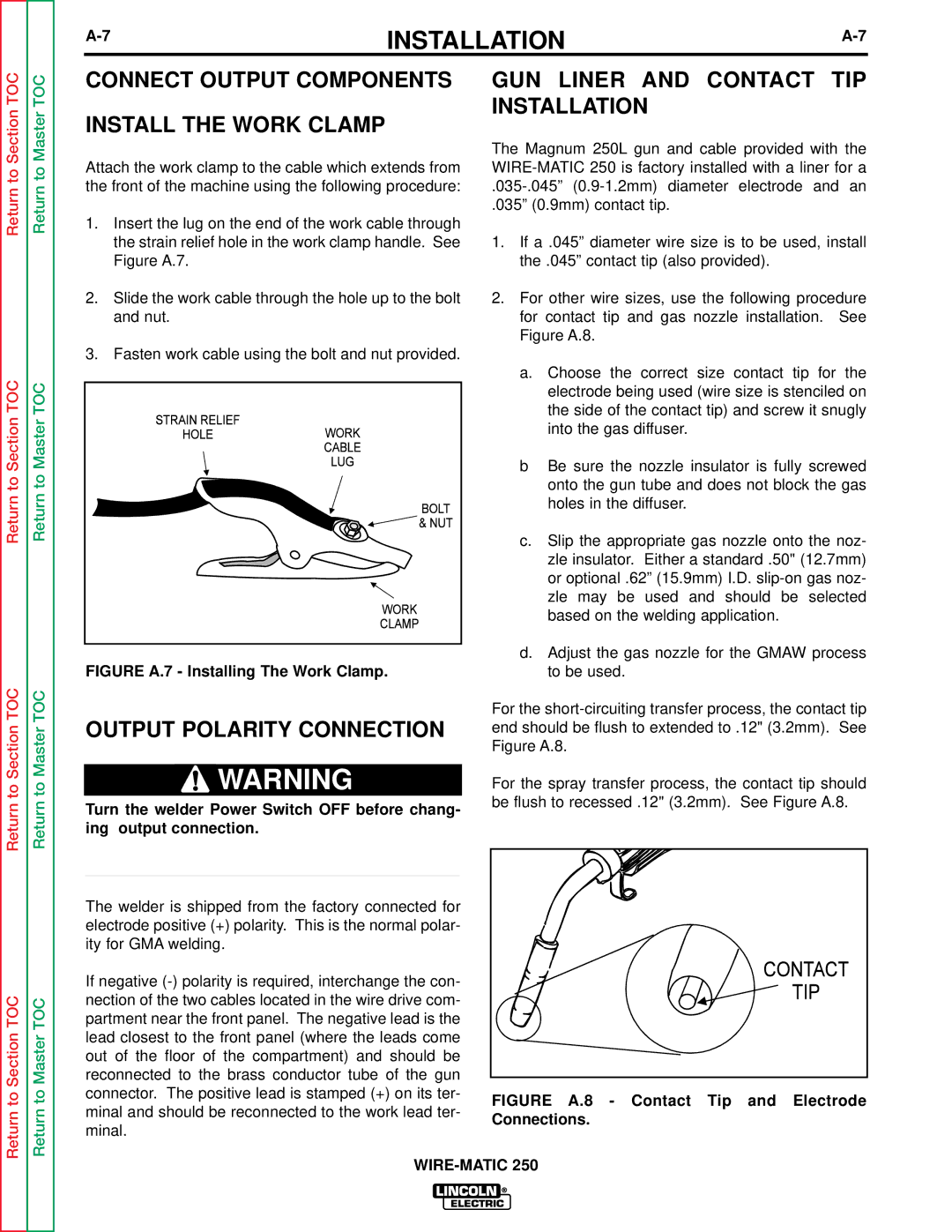

| the strain relief hole in the work clamp handle. See | 1. If a .045” diameter wire size is to be used, install | ||

|

|

| Figure A.7. | the .045” contact tip (also provided). |

| |

|

| 2. Slide the work cable through the hole up to the bolt | 2. For other wire sizes, use the following procedure | |||

|

|

| and nut. | for contact tip and gas nozzle installation. | See | |

|

|

|

| Figure A.8. |

| |

3. Fasten work cable using the bolt and nut provided.

TOC | TOC | a. | Choose the correct size contact tip for the |

| electrode being used (wire size is stenciled on | ||

|

|

| |

Section | Master | b | the side of the contact tip) and screw it snugly |

Be sure the nozzle insulator is fully screwed | |||

|

|

| into the gas diffuser. |

to | to |

| onto the gun tube and does not block the gas |

Return | Return |

| holes in the diffuser. |

|

|

| |

|

| c. | Slip the appropriate gas nozzle onto the noz- |

|

|

| zle insulator. Either a standard .50" (12.7mm) |

|

|

| or optional .62” (15.9mm) I.D. |

|

|

| zle may be used and should be selected |

|

|

| based on the welding application. |

|

| d. | Adjust the gas nozzle for the GMAW process |

|

| FIGURE A.7 - Installing The Work Clamp. | to be used. |

TOC | TOC | OUTPUT POLARITY CONNECTION |

| For the |

|

|

| ||

Section | Master |

| end should be flush to extended to .12" (3.2mm). See | |

|

| Figure A.8. | ||

|

|

|

| |

|

|

|

|

|

to | to | WARNING |

| For the spray transfer process, the contact tip should |

|

| be flush to recessed .12" (3.2mm). See Figure A.8. | ||

Return | Return | Turn the welder Power Switch OFF before chang- |

| |

|

| |||

|

|

|

| |

|

| ing output connection. |

|

|

|

| ____________________________________ |

|

|

|

|

|

|

The welder is shipped from the factory connected for electrode positive (+) polarity. This is the normal polar- ity for GMA welding.

|

| If negative |

|

|

|

|

|

| |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| ||

TOC | TOC | nection of the two cables located in the wire drive com- |

|

|

|

|

|

| |

|

|

|

|

|

| ||||

partment near the front panel. The negative lead is the |

|

|

|

|

|

| |||

|

|

|

|

|

|

|

| ||

Section | Master | lead closest to the front panel (where the leads come |

|

|

|

|

|

| |

out of the floor of the compartment) and should be |

|

|

|

|

|

| |||

|

|

|

|

|

|

|

| ||

|

| reconnected to the brass conductor tube of the gun |

|

|

|

|

|

| |

|

|

|

|

|

|

|

| ||

to | to | connector. The positive lead is stamped (+) on its ter- | FIGURE A.8 - Contact Tip and Electrode | ||||||

minal and should be reconnected to the work lead ter- | |||||||||

Return | Return | Connections. | |||||||

minal. | |||||||||

|

| ||||||||

|

|

|

|

|

|

|

| ||

|

|

| |||||||