Refrigeration System |

|

|

| Section 7 | ||||||||

|

|

|

|

|

|

|

|

|

| |||

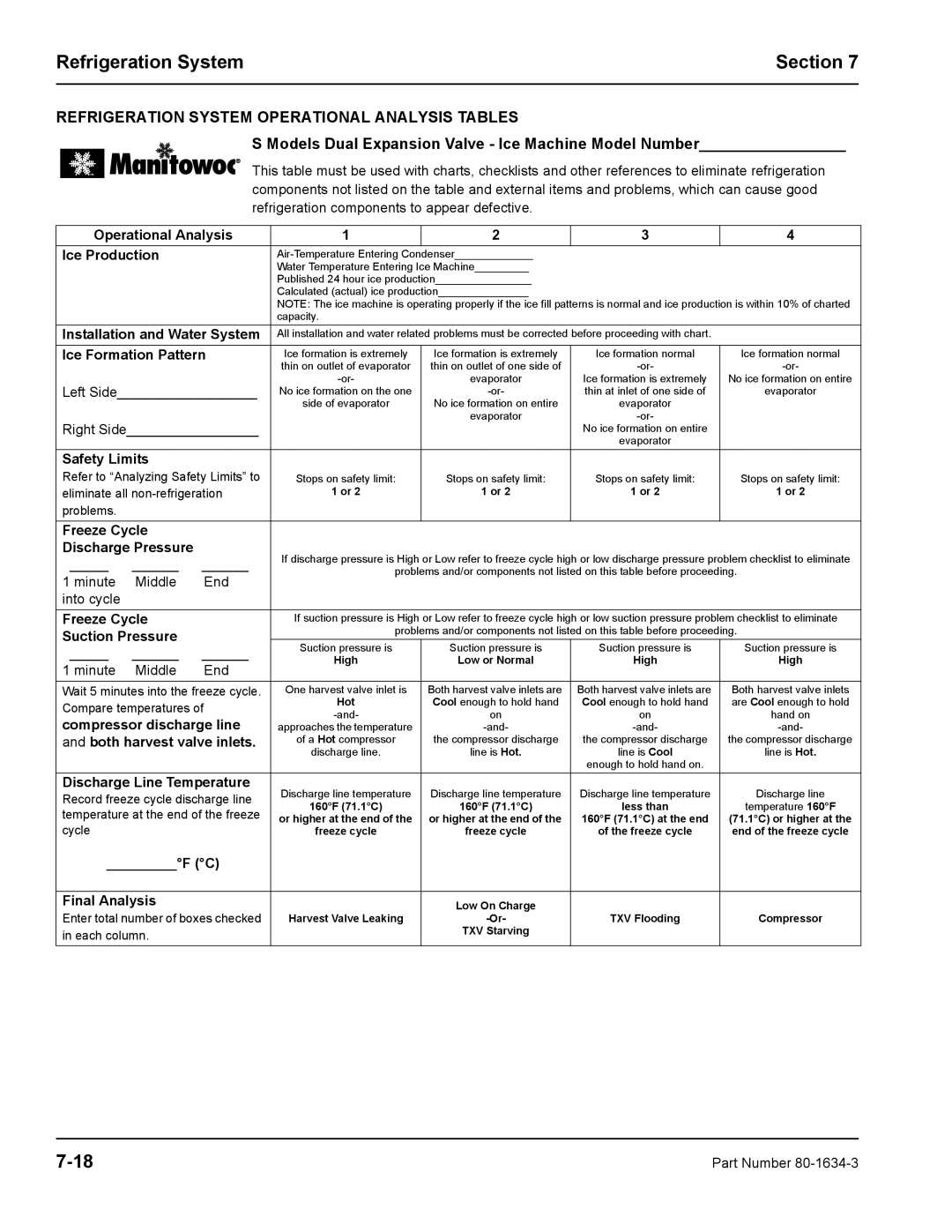

REFRIGERATION SYSTEM OPERATIONAL ANALYSIS TABLES |

|

|

| |||||||||

|

|

|

|

|

| S Models Dual Expansion Valve - Ice Machine Model Number_________________ | ||||||

|

|

|

|

|

| This table must be used with charts, checklists and other references to eliminate refrigeration | ||||||

|

|

|

|

|

| |||||||

|

|

|

|

|

| components not listed on the table and external items and problems, which can cause good | ||||||

|

|

|

|

|

| refrigeration components to appear defective. |

|

|

| |||

|

|

|

|

|

|

|

|

|

| |||

| Operational Analysis | 1 | 2 | 3 | 4 |

| ||||||

| Ice Production |

|

|

|

| |||||||

|

|

|

|

|

|

| Water Temperature Entering Ice Machine_________ |

|

|

| ||

|

|

|

|

|

|

| Published 24 hour ice production________________ |

|

|

| ||

|

|

|

|

|

|

| Calculated (actual) ice production_______________ |

|

|

| ||

|

|

|

|

|

|

| NOTE: The ice machine is operating properly if the ice fill patterns is normal and ice production is within 10% of charted | |||||

|

|

|

|

|

|

| capacity. |

|

|

|

| |

| Installation and Water System | All installation and water related problems must be corrected before proceeding with chart. |

|

| ||||||||

| Ice Formation Pattern | Ice formation is extremely | Ice formation is extremely | Ice formation normal | Ice formation normal | |||||||

|

|

|

|

|

|

| thin on outlet of evaporator | thin on outlet of one side of | ||||

| Left Side__________________ | evaporator | Ice formation is extremely | No ice formation on entire | ||||||||

| No ice formation on the one | thin at inlet of one side of | evaporator | |||||||||

|

|

|

|

|

|

| side of evaporator | No ice formation on entire | evaporator |

|

| |

| Right Side_________________ |

| evaporator |

|

| |||||||

|

|

| No ice formation on entire |

|

| |||||||

|

|

|

|

|

|

|

|

| evaporator |

|

| |

| Safety Limits |

|

|

|

|

|

| |||||

| Refer to “Analyzing Safety Limits” to | Stops on safety limit: | Stops on safety limit: | Stops on safety limit: | Stops on safety limit: | |||||||

| eliminate all | 1 or 2 | 1 or 2 | 1 or 2 | 1 or 2 | |||||||

| problems. |

|

|

|

|

|

|

|

|

| ||

| Freeze Cycle |

|

|

|

|

|

| |||||

| Discharge Pressure |

| If discharge pressure is High or Low refer to freeze cycle high or low discharge pressure problem checklist to eliminate | |||||||||

_____ | ______ | ______ | ||||||||||

problems and/or components not listed on this table before proceeding. | ||||||||||||

| 1 minute | Middle | End | |||||||||

|

|

|

|

|

| |||||||

| into cycle |

|

|

|

|

|

|

|

|

| ||

| Freeze Cycle |

| If suction pressure is High or Low refer to freeze cycle high or low suction pressure problem checklist to eliminate | |||||||||

| Suction Pressure |

| problems and/or components not listed on this table before proceeding. | |||||||||

_____ | ______ | ______ | Suction pressure is | Suction pressure is | Suction pressure is | Suction pressure is | ||||||

High | Low or Normal | High | High | |||||||||

| 1 minute | Middle | End | |||||||||

|

|

|

|

|

| |||||||

| Wait 5 minutes into the freeze cycle. | One harvest valve inlet is | Both harvest valve inlets are | Both harvest valve inlets are | Both harvest valve inlets | |||||||

| Compare temperatures of | Hot | Cool enough to hold hand | Cool enough to hold hand | are Cool enough to hold | |||||||

| on | on | hand on | |||||||||

| compressor discharge line | |||||||||||

| approaches the temperature | |||||||||||

| and both harvest valve inlets. | of a Hot compressor | the compressor discharge | the compressor discharge | the compressor discharge | |||||||

|

|

|

|

|

|

| discharge line. | line is Hot. | line is Cool | line is Hot. | ||

|

|

|

|

|

|

|

|

| enough to hold hand on. |

|

| |

| Discharge Line Temperature | Discharge line temperature | Discharge line temperature | Discharge line temperature | Discharge line | |||||||

| Record freeze cycle discharge line | |||||||||||

| 160°F (71.1°C) | 160°F (71.1°C) | less than | temperature 160°F | ||||||||

| temperature at the end of the freeze | |||||||||||

| or higher at the end of the | or higher at the end of the | 160°F (71.1°C) at the end | (71.1°C) or higher at the | ||||||||

| cycle |

|

|

|

| freeze cycle | freeze cycle | of the freeze cycle | end of the freeze cycle | |||

|

| _________°F (°C) |

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

| ||

| Final Analysis |

|

| Low On Charge |

|

|

| |||||

| Enter total number of boxes checked | Harvest Valve Leaking | TXV Flooding | Compressor | ||||||||

| in each column. |

|

| TXV Starving |

|

|

| |||||

Part Number |