05/08 Rev. AB | OPERATOR’S HANDBOOK | Specifications | |||

|

| 9844/9854 |

|

| |

|

|

|

|

| |

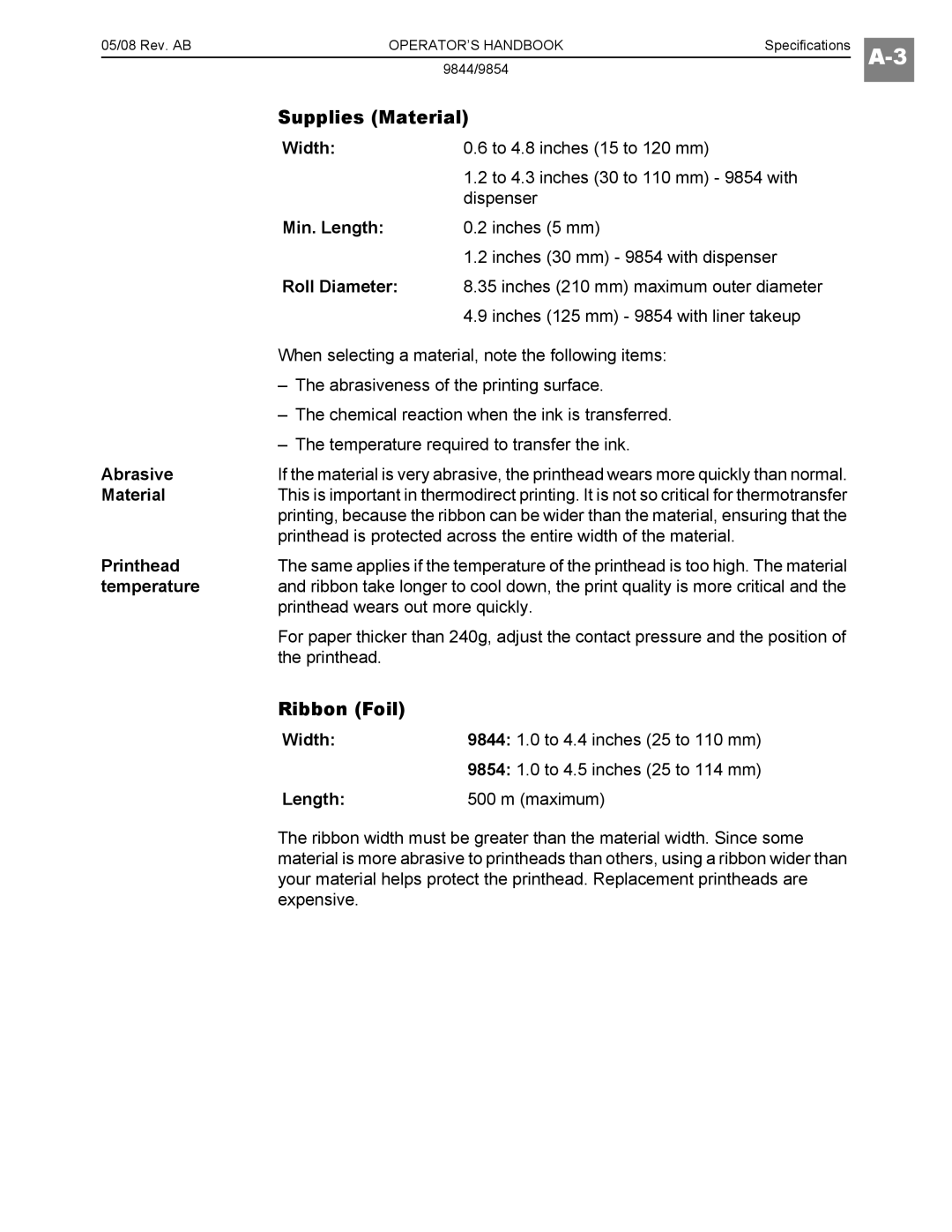

| Supplies (Material) |

|

|

| |

| Width: | 0.6 to 4.8 inches (15 to 120 mm) |

|

|

|

|

| 1.2 to 4.3 inches (30 to 110 mm) - 9854 with |

| ||

|

| dispenser |

|

|

|

| Min. Length: | 0.2 inches (5 mm) |

|

|

|

|

| 1.2 inches (30 mm) - 9854 with dispenser |

| ||

| Roll Diameter: | 8.35 inches (210 mm) maximum outer diameter |

| ||

|

| 4.9 inches (125 mm) - 9854 with liner takeup |

| ||

| When selecting a material, note the following items: |

|

|

| |

| – The abrasiveness of the printing surface. |

|

|

| |

| – The chemical reaction when the ink is transferred. |

|

|

| |

| – The temperature required to transfer the ink. |

|

|

| |

Abrasive | If the material is very abrasive, the printhead wears more quickly than normal. |

| |||

Material | This is important in thermodirect printing. It is not so critical for thermotransfer |

| |||

| printing, because the ribbon can be wider than the material, ensuring that the |

| |||

| printhead is protected across the entire width of the material. |

|

|

| |

Printhead | The same applies if the temperature of the printhead is too high. The material |

| |||

temperature | and ribbon take longer to cool down, the print quality is more critical and the |

| |||

| printhead wears out more quickly. |

|

|

| |

| For paper thicker than 240g, adjust the contact pressure and the position of |

| |||

| the printhead. |

|

|

|

|

| Ribbon (Foil) |

|

|

|

|

| Width: | 9844: 1.0 to 4.4 inches (25 to 110 mm) |

|

|

|

|

| 9854: 1.0 to 4.5 inches (25 to 114 mm) |

|

|

|

| Length: | 500 m (maximum) |

|

|

|

| The ribbon width must be greater than the material width. Since some |

| |||

| material is more abrasive to printheads than others, using a ribbon wider than |

| |||

your material helps protect the printhead. Replacement printheads are expensive.