Printer

Sato America, Inc

Table of Contents

Troubleshooting

Printer Configuration

Maintenance

Appendix

Offset

Introduction

Equipment Damage

About this Manual

1a, Primary Components

General Description

Operator Panel Features LED Definition

Control Features

Operator Panel

Technical Data

Processing

Physical Characteristics

Power

Environmental

Ribbon

Command

Sensing

Media

Character Font Capabilities

Postnet

Barcode Capabilties

UPC A/E

MSI

Installation

Unpacking & Parts Identification

Unpacking & Parts Identification

Printer Installation

Site Location

Cable Connection

Media & Ribbon Loading

Media Selection

3b, Fan-fold Media Loading

Operational Mode Selection

TEAR-OFF Mode

Continuous Mode

Label Print Direction

RS232C HIGH-SPEED Serial Interface

Interface Specifications

Accessories Installation unit for guidance

Interface Selection

OFF ON/X-OFF

PIN Direction Signal Definition

OFF

OFF ODD Even None

ON/X-OFF Cable Requirements

READY/BUSY Cable Requirements DB9

Host Direction

Printer

ACK

Specifications

PIN Assignments Signal Direction

IEEE1284 Parallel Interface

Local Area Network LAN Ethernet

Dipswitch Settings

Setting

Universal Serial BUS USB

Software Specifications

Accessory EXT Connector PIN Assignments

Direction Signal Definition

Ssid

802.11G Wireless

Switch Setting

LED Indicator Status Description

READY/BUSY Interface Signals

EXT Accessory Port

Low 0V when the printer is offline

+24V +/- 10% @2A Power for external devices

Waiting

8b, Timing Chart Repeat Print

Interface Signals

ALL Interfaces

Cable Requirements

50 of 500 items in the history buffer

Receive Buffer Control

Interface Installation

Accessories Installation

Printer Configuration

Unit 4 Printer Configuration

Dipswitch Settings

DSW1 Default Settings

DSW1 Configuration

Configuration

Function Description

DSW1 Function

DSW3 Default Settings

Normal Mode

Configuration Modes

Advanced Mode

Advanced Mode

User Download Mode

User Download Mode

Service Mode

Service Mode

Card Mode

Card Mode

DSW7 on Line + Feed + Power

Protocol Initialization Mode

Counters Mode

Counters Mode

Test Print Mode

Test Print Mode

Yes

Boot Download Mode

10, Flash Memory Download Mode

Flash Memory Download Mode

11, Default Setting Mode

Default Setting Mode

Online QTY

HEX Dump Mode

13, Maintenance Mode

Maintenance Mode

Menu Description

Normal Mode Table

Advanced Mode Table

Menu Definition Tables

Proportional is contemporarily preferred

Real-time clock is not installed

Point respectively

Stream including graphics and 2D barcodes

Service Mode Table

Operator to manage the expanded memory card

As most important where conflicting data exists

Is only a transitional menu screen for the Service Mode

Languages are provided as options

Card Mode Table

Transitional menu screen to access the Counters Mode

Allows the selection of which counter to be viewed to reset

Or use

Font The contents of the installed fonts

Is the initial screen of the Test Print Mode

Configuration The printer’s configuration settings

Barcode The printer’s installed barcodes

Also prompts the operator on how to proceed

Reboot the printer to return to normal operation

Select the Interface option for a standard download

Clear its Eeprom of all data

To proceed to the Factory Mode

Print buffer

Clear

Page. These are the only two options

Maintenance Mode Table

Troubleshooting

Error Signal Troubleshooting

Troubleshooting Table

Smeared Print Images

No Printed Image

Printer Creates a Blank Label

Incorrect Label Positioning

CHK Troubleshooting Step

Interface Troubleshooting

LAN Ethernet Interface

Power

Test Print Troubleshooting

Test Label Printing

Sample Test Label

Maintenance

PRINTER, Excersize Care to Prevent Print Head Damage

Cleaning Procedures

Print Head Replacement

Replacement Procedures

1b, Print Head Replacement

Interface Board Replacement

Interface Board Replacement

Fuse Replacement

Fuse Replacement

Print Head Balance Adjustment

Adjustment Procedures

5a, Print Head Alignment

Print Head Alignment

Head Balance and Print Head Alignment

Ribbon Guide Alignment

Label Sensor Positioning

Label Sensor Positioning

Ribbon Spindle Tensioning

Ribbon Spindle Tensioning

Operational Adjustments

Potentiometer DESCRIPTION/PROCEDURE

Darkness

Print Base Reference Position

Appendix

Direction

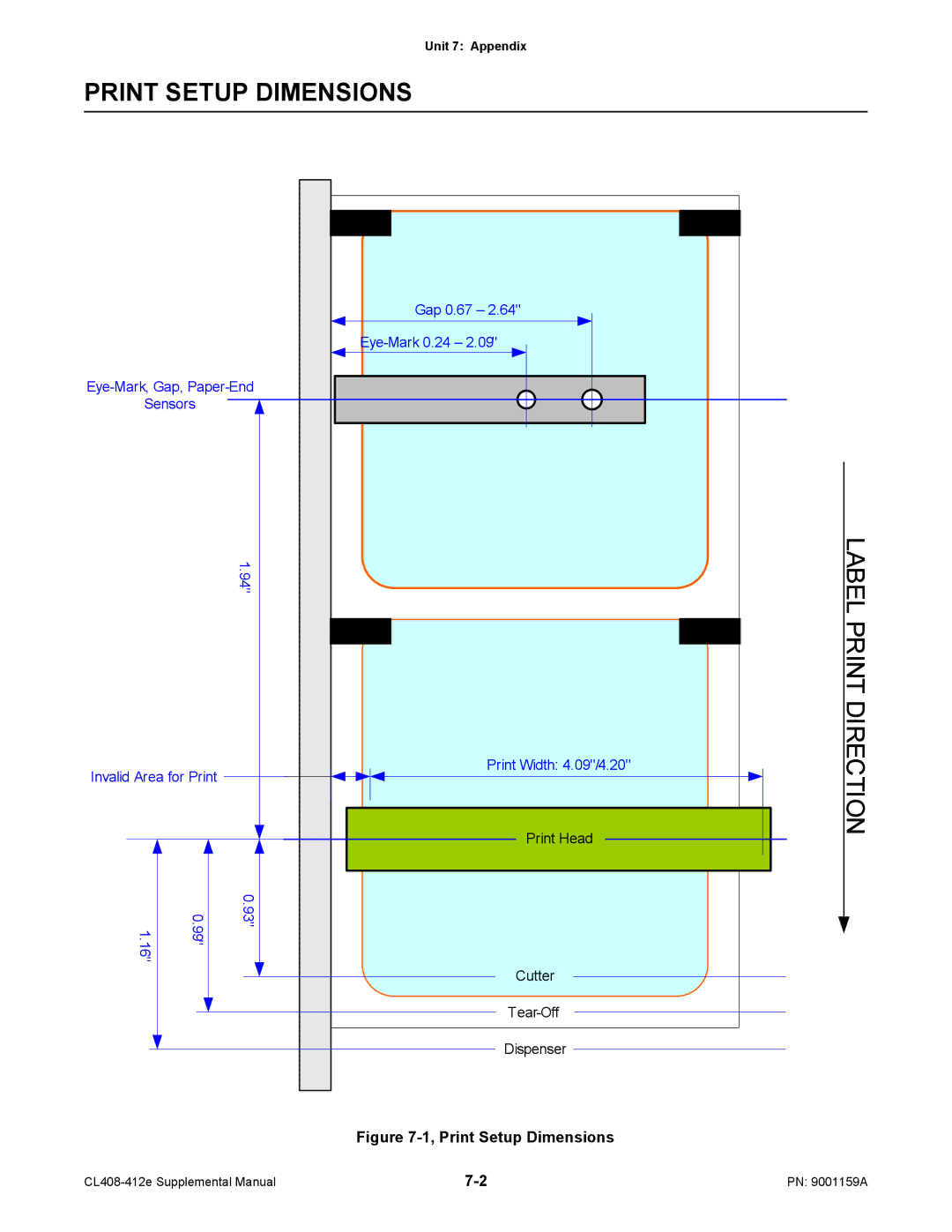

Print Setup Dimensions

Label Reference Position

Label Reference Position Diagram

Glossary

Glossary

Ascii

Half. The core is convexed and the cavity is concaved

Bytes Collection of 8 bits used in the binary system

Being its mating half

Is a plug male and the other is a socket female

Data transmission, seven additional bits are required

DPI

Dram

Eeprom

To attach two or more objects

Power

Tag would typically have to be removed from its object

Next label for printing

LED

LCD

Or voltage divider Primary

Potentiometer

Rfid

RAM

RF/AIS

RF/DC

Sbpl

ROM

RPM

SAM

Sram

Glossary