11/2007

Zelio Logic Smart Relay

Table of Contents

Transfer Menu

Configuration Menu

Default Menu

Clear Program Menu

Sample Application

Diagnostics

Implementing a Basic Application

Debugging an Application

Important Information

Safety Information

Safety Information

At a Glance

About the Book

Presentation

Initial Power up and Discovering

Chapter Name Initial Power up and Discovering

Topic

Subject of this Chapter Whats in this Chapter?

Preliminary Advice

Safety

Risk of Electric SHOCK, Explosion or Electric Arcing

Involuntary Operation of Equipment

Introduction Description Smart Relay Front Panel

Presentation of the Smart Relay Front Panel

U 2 5 S E P 1 6 4

Prompt Element

Description of the LCD

An Active input or output is displayed in reverse video

Rectified and filtered

Characteristics and Connections

Regulated

Menu/OK Key

Control Keys on the Front Panel of the Smart Relay

N / S T O P

Shift Key

Navigation keys are used to move left or right, down or up

Round for a link only in programming mode

Zx Keys

Are marked above the keys

Menus Contextual menu appears Illustration Ins + Param Del

Using the contextual menu functions

Contextual

View

Examples

Introduction Language Selection

Step Action

E a R P R O G A N S F E R R S I O N N G U a G E

Or then

D E O P

View A N G E D / H U L 2 0 0 2 7 3 0 s Secs / WK

Then Times in LD mode

Modification of Date and Hour

View 3 4 B C D E

Chapter Chapter Name

Functions Accessible from the Front Panel

Subject of this Section Whats in this Part?

To return to the previous menu, press left navigation key

Overview of the Functions Accessible from the Front Panel

Line flashes to indicate where you are positioned

Extensions

Certain menus are specific to either LD or FBD mode

Configuring

Differences Between LD FBD Modes

Input/Output Screen

N 2 2 S E P 1 5 5

Programming type LD or FBD Mode Stop or RUN

Inputs-Outputs Screen

3 4 5

Main Menu

Access to

T e 1 1 / 2 0 0

Switching Between Screens

Text and Display screen

L u e c o u n t e r

Result Param is displayed at the bottom of the screen

Press the Shift key white key to display the contextual menu

Subject of this Chapter

Programming Menu

Chapter?

Following manner

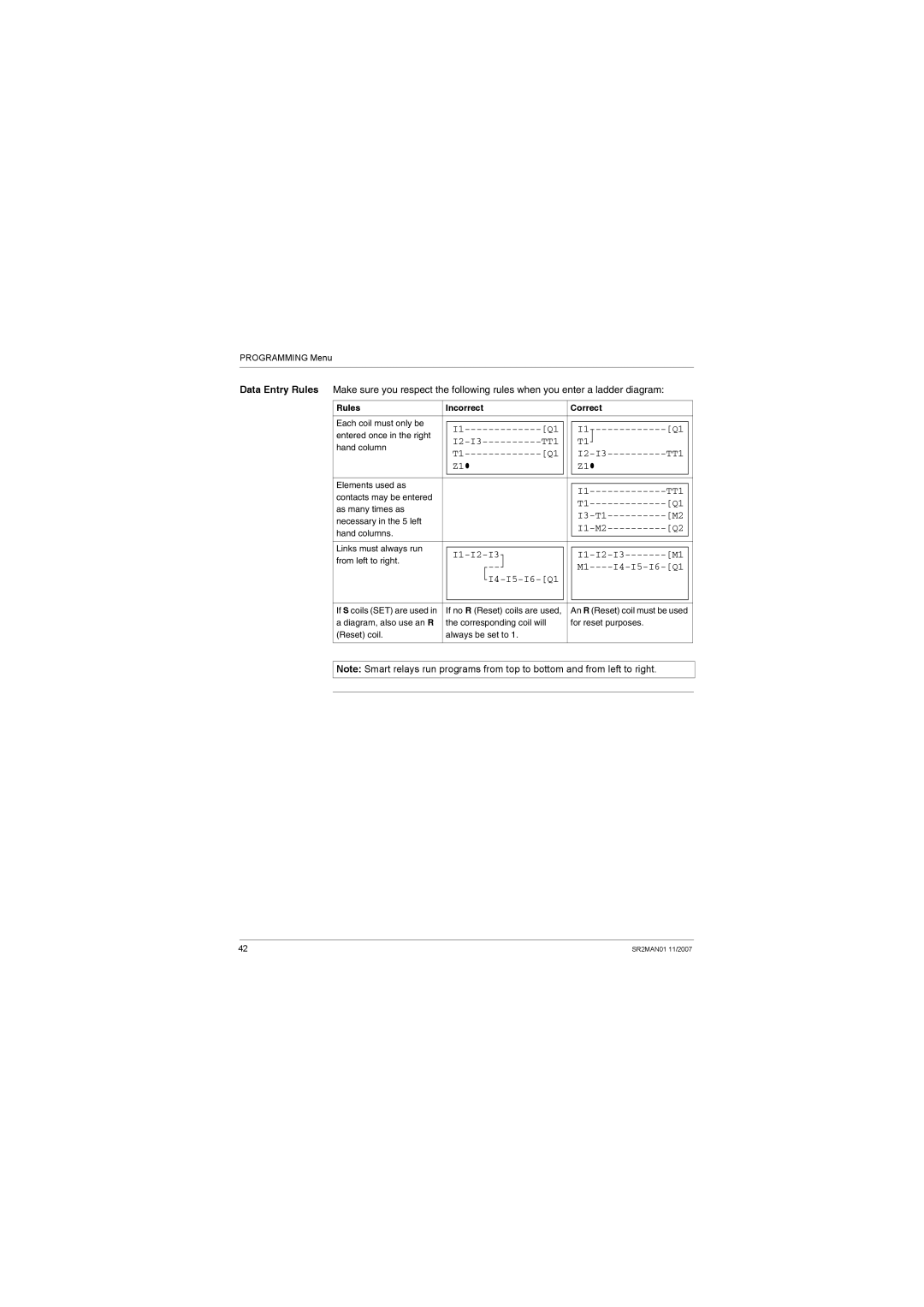

Rules for Entering Ladder Diagrams

Smart relay allows you to enter 120 line Ladder diagrams

Rules Incorrect Correct

M1----I4-I5-I6-Q1

Ins Del

Method for Entering a Contact or Coil

Description Entering an Element

Modifying an element Initialization Deleting an Element

Steps 7 to 9 are only necessary when entering a coil

Description Entering a Link

Entering a Link

Deleting a Link Replacing a Link with a Contact

Entry of Function Block Parameters

Description Accessibility of parameters

To modify the parameters of an existing element, simply

Entering Parameters on Creation of the Block

Ins. + Param Del

Modifying Parameters Existing Blocks

Insertion

Deletion and Insertion of Diagram Lines

Deletion

Parameters menu

LD mode

Parameters Menu

RUN Mode

FBD mode Parameter Modification

Monitoring Menu

To modify the parameters, proceed as follows

Following three choices for starting the program

RUN/STOP Menu

Startup

Off Smart Relays Without Screen

O P

Configuration Menu

Password to perform certain operations

Password Menu

Removing

Entering Password

Password

E a R 1

3 0 M I N U T E S

E a R 2

Fast

Filter Menu

Description Filter-Type Selection

Filtering Commutation Response time Slow

Zx Keys Menu

Description Zx Keys in RUN Mode

Illustration C L E = 0 5 x 0 2 m S

Watchdog Cycle Menu

Actions Cycle Time Watchdog Configuration

Description Clearing the Program

Clear Program Menu

Clear Prog Menu

M O R Y Z E L I O

Transfer Menu

L I O M E M O R Y

Module → Backup Memory Transfer

RUN, remove the Eeprom cartridge SR2 MEM02

Backup Memory → Module Transfer

With firmware on

Absence of backup memory

Application

Incompatible

MEM02

Use of SR2 MEM01 and SR2

R M W a R E 0 1

Version Menu

D U L E S R 3 B 2 6 1 B D

R D W a R E 0 1

1 4 1 B D

A L I a N O

Language Menu

Reset to Zero of the Fault Counter Illustration

Default Menu

Fault Menu

Fault 0 0

Fault Types

Default Menu

A N G E

Change DATE/TIME Menu

Steps Description

Clock Configuration

Example

Smart relays with a clock

Change SUMMER/WINTER Menu

To configure automatic time change, proceed as follows

Configuration of the Time Change

Chapter Chapter Name LD Language Elements

LD Language

LD Language Elements

Composition

Ladder Diagrams

Diagram Panel of a smart relay

Introduction

Use as a Contact

Normally open mode

Normally closed mode

Discrete Inputs

Contact

Modification

State of a

Zx Keys

Place the mouse over the letter representing the contact

Normally open mode direct state is inactive

Normally closed mode reverse state is active

Contact

Auxiliary Relays

They can be used as internal variables

Unlatch mode

Contactor mode

Impulse relay mode

Latch mode

Normally open mode

Following inputs I1, I2, I3, I4, I5 and IB

Modifying the Mode of a Coil or a Contact

Window

Latching

Initialization

Activated

Smart relay and any extensions

Discrete Discr Outputs

SQ1

Window associated with the output

Timers

Reset input

Coil TT Command Input

Coil RC Reset Input

Command input

Type of timer

Parameter lock

Preset value

Unit Symbol Form Maximum value

Time unit

Time unit

Command input timing diagram

Timer type

Number Parameter Description

Active, control held down type a

Following diagram shows the operation of the type a timer

Off delay type C

Following diagram shows the operation of the type C timer

Timing after pulse type W

Combination of a and C

On pulse one shot type B

Flasher unit, Press to start/stop, Synchronous type d

Following diagram shows the operation of the type D timer

Following diagram shows the operation of the type L timer

Flasher unit, control held down synchronously type D

Current values is are zeros

Following diagram shows the operation of the type T timer

Normally closed mode inverse state is active

Time on addition type T

Preset value t Illustration Timers configuration screen

Coil DC Counting Direction input

Coil RC Reset Initial Counter State Input

Counters

Coil CC Counting Pulse Input

Counting direction input

Reset Initial Counter State input

Every time key Z1 is pressed, the counter starts from

Contact is conducting as long as

Type of counting

Counter output Counter output timing diagram

Number Parameter Description Command input

Counter reset input timing diagram

Initialization R Counting

Examples

Mode toward the preset value

Current value is zero

Fast Counter

Enable function input

Coil TK1 Enable function input

Coil RK1 Reset initial counter state input

120

Duration of pulse

Symbol of the Duration of pulse parameter

Cycle type

Symbol of the Parameter Lock parameter Verrouillé

Number Parameter Description Cycle type Single/Repetitive

Value Counter reset to its initial state

Current Counter

Up-Counting in Single Cycle Mode

Up-counting in Repetitive Cycle Mode

Down-Counting in Single Cycle Mode

Down-Counting in Repetitive Cycle Mode

TK1 RK1

Counter Comparators

Analog Comparators

Values to compare

Configuration from Front Panel

Xl Comparison Operator

X1 H ≤ x2≤ x1 + H

Parameter locking

Reference value

Hysteresis parameter

N a L O G ≤ x = I d = I e

N a L O G

≤ ξ 2 ≤ x 1 + H

= 4 = R = 1 = I e

Comparison operator no is chosen, that is ≤

Temperature is below 20 C

Clocks

Mode or its inverse state mode normally closed, see below

Symbol of the normally open contact, representing a clock

Symbol of the normally closed contact, representing a clock

Operating ranges

D / W O N O F F

Relay

Number Parameter

Interval Start on Friday at End on Monday at

Day at

2 3

2 3 4

Display from the Text screen to the inputs-outputs screen

Texts

These function blocks are used as coils

Only the block with the highest number is displayed

Display deactivation

Display Activation coil Display Deactivation coil

Display Activation

Used as a Coil

LCD Screen Backlighting

Check the Activate Summer/Winter Time Change box

Access

Change to Summer / Winter Time

Europe Europe

Modifying the Mode of a Coil or a Contact Initialization

Words sent by the master

Modbus Inputs/Outputs

Smart relay

Message

Use of the Coil Command input

Configuration from the Front Panel Initialization

Creating and Debugging an Application

Implementing a Basic Application

Normal electrical diagram Ladder diagram

Presentation of Ladder Diagrams

Works a two-way switch

Mon

Module Wiring Below, an illustration of smart relay wiring

Operation Can be used in place of two position switches

Input I wired on the smart relay

Using the Reverse Function

Practical Example

Electrical diagram Connection to the smart relay

Ladder diagram 1 Light off when idle

Off delay Operating Electrical diagram

Equivalencies Between Notations

Electrical symbol Ladder symbol

Notation Used by the Smart Relay

156

Step Action Screen Comment

Application Implementing a Two-way Switch

Description Go to the Programming Screen

To enter the contacts in the first line, proceed as follows

Entering Contacts First Line

Step Action Screen

Fois

Entering the Coil and Joining it to the Contacts

To enter the contacts in the second line, proceed as follows

Entering Contacts Second Line

Flashes

Joining the Second Line to the First

To join the second line to the first, proceed as follows

Second 1 in the second line

Programming is selected

Launching the Program

To launch the program, proceed as follows

Debugging an Application

N L D

Module in RUN Mode Viewing Status

Menus RUN mode

Changing Ladder Diagrams

Dynamic Mode Ladder Diagrams

Viewing Ladder Diagrams

3 4 5 N 2 2 S E P 1 5 5

Using Z Keys as Pushbuttons

Presentation

Dynamic Mode Function Block Parameters

Accessing

Menus Not. Here is a summary table

Dynamic Mode Menus

Dynamic Mode

Option defined in the parameters window

Smart Relay Reaction to a Power Failure

Event of a power failure

Example of a non-locked coil

Safety Mode

With the clock function block 1 configured as follows

This allows

Backup and Transfer of Ladder Diagrams19

Saving and Transferring Ladder Diagrams

Memory optional and vice-versa

Sample Application

Specifications

Outputs

Specification Analysis

Inputs

Button

Smart relay label Name

Special function blocks

Description Implementing Ladder Diagram

Implementing the Solution

Function Blocks

O F F 1 2 0

Fan operating duration if the CO

Function block Comment Analog function block A1

Compares the measured CO 2 level

With the threshold value 8.5

Chapter Name Diagnostics 187

Diagnostics

Smart Relay Messages 188 Frequently Asked Questions 189

Message Cause Corrective action

Relay, their possible causes and how to remedy the problem

Smart Relay Messages

Questions are listed here

Frequently Asked Questions

Answer

Frequently

Asked Questions

Appendix?

Appendices

This section contains product-related appendices

Appendix contains the following chapters

Chapter

Compatibility

Subject of this

Version

Smart relay firmware version

Memory cartridge

Memory Cartridge to Smart Relay

Type of memory cartridge Version of firmware compatible

Smart relay firmware language

Index

Change DATE/TIME Change SUMMER/WINTER, 83 Clear Prog

Menu

35007143