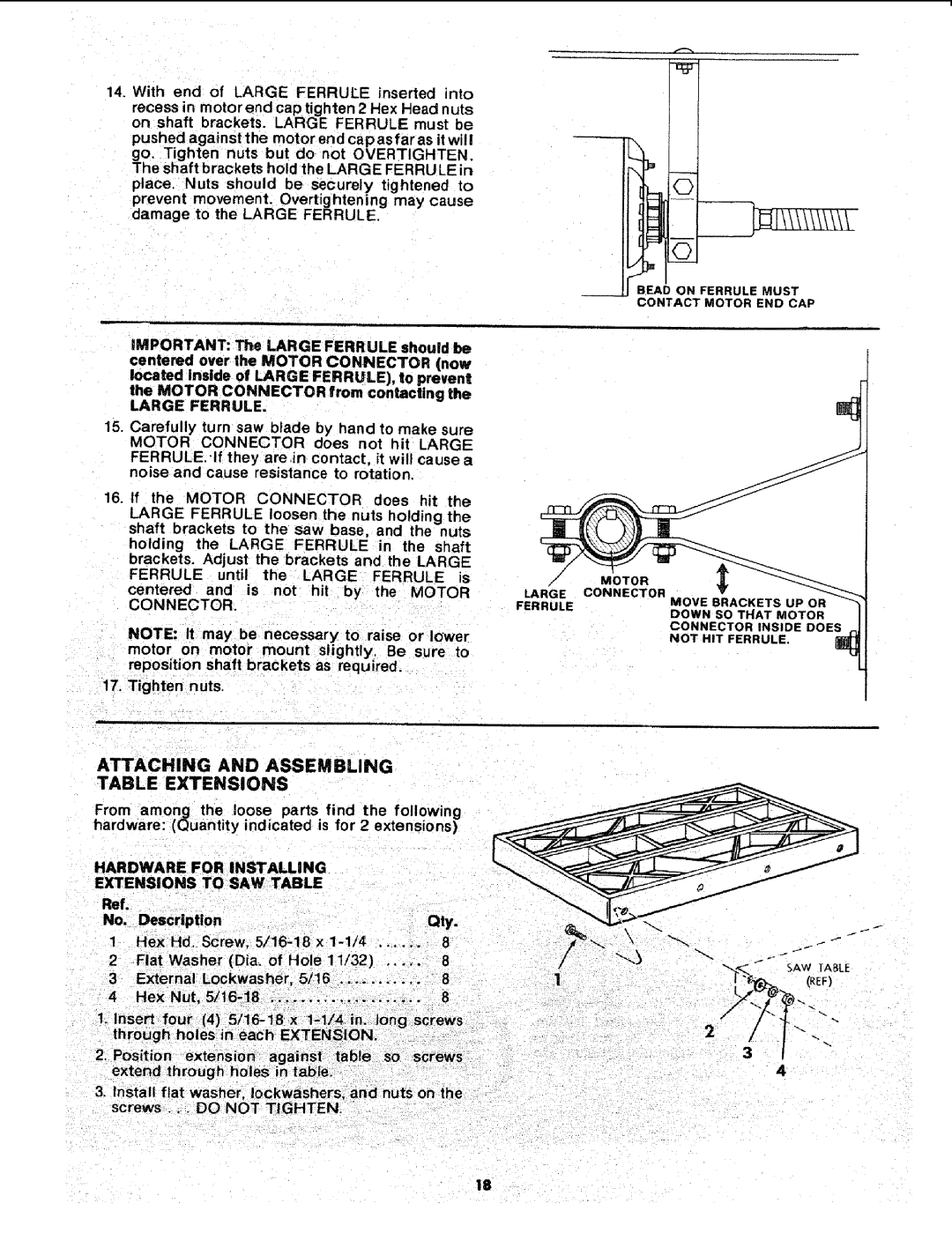

14.With end of LARGE FERRULE inserted into

recess in motor end cap tighten 2 Hex Head nuts on shaft brackets. LARGE FERRULE must be

pushed against the motor end ca p as far as it wil I go. Tighten nuts but do not OVERTIGHTEN. The shaft brackets hold the LARGE FERRULE in place. Nuts should be securely tightened to prevent movement. Overtightening may cause damage to the LARGE FERRULE.

IMPORTANT: The LARGE FERRULE should be centered over the MOTOR CONNECTOR (now located Inside of LARGE FERRULE), to prevent

the MOTOR CONNECTOR from contacting the

LARGE FERRULE.

15.Carefully turn saw blade by hand to make sure MOTOR CONNECTOR does not hit LARGE

16.If the MOTOR CONNECTOR does hit the

LARGE FERRULE loosen the nuts holding the shaft brackets to the saw base, and the nuts

holding the LARGE FERRULE in the shaft brackets. Adjust the brackets and the LARGE FERRULE until the LARGE FERRULE is

centered and is not hit by the MOTOR CONNECTOR.

NOTE: It may be necessary to raise or lower

motor on motor mount slightly. Be sure to reposition shaft brackets as required.

17.Tighten nuts.

ATTACHING AND ASSEMBLING

TABLE EXTENSIONS

From among the loose parts find the following hardware: ((_uantity indicated is for 2 extensions)

HARDWARE | FOR INSTALLING |

|

EXTENSIONS | TO SAW TABLE |

|

Ref. |

|

|

No. Description | Qty. | |

1Hex Hd. Screw,

2 | Flat Washer (Dia. of | Hole 11/32) | 8 |

3 | External Lockwasher, | 5/16_ | 8 |

__BEAD ON FERRULE MUST

CONTACT MOTOR END CAP

/ | MOTOR |

|

| |

z |

|

| ||

LARGE | CONNECTOR | BRACKETS | UP OR | |

FERRULE | MOVE | |||

DOWN | SO THAT | MOTOR | ||

|

CONNECTOR INSIDE DOES

NOT HIT FERRULE.