EVS Toolroom Lathes | O P E R A T I O N | For Machines Mfg. Since 7/09 |

Mounting Chuck or Faceplate

The

To mount a chuck or faceplate:

1.DISCONNECT LATHE FROM POWER!

2.Lay a chuck cradle (see Figure 39) or plywood under the chuck or faceplate and over the bedway to protect the precision ground surfaces from damage and reduce injury if fingers get pinched.

3.Clean away debris and oily substances from the mating surfaces of the spindle and chuck or faceplate.

4.Inspect and make sure that all camlock studs are undamaged, are clean and lightly oiled, and that the camlock stud cap screws are in place and snug.

Never install a chuck or faceplate without having the camlock cap screws in place or fully tightened. If you ignore this notice, the chuck may not be removable since the camlock studs may turn with the camlocks and never release.

5.Position the chuck/faceplate in front of the spindle nose, align the chuck timing marks, as shown in Figure 42, and align the cam- lock studs with the sockets, then carefully insert the chuck or faceplate onto the spindle.

6.Tighten camlocks in a star pattern to draw the chuck up evenly on all sides while reducing chance of alignment, and make sure to tighten camlocks in an incremental manner to ensure that no camlock gets fully tightened all at once (i.e., snug the camlocks on the first pass, then moderately tighten on the next pass, then fully tighten on the third pass).

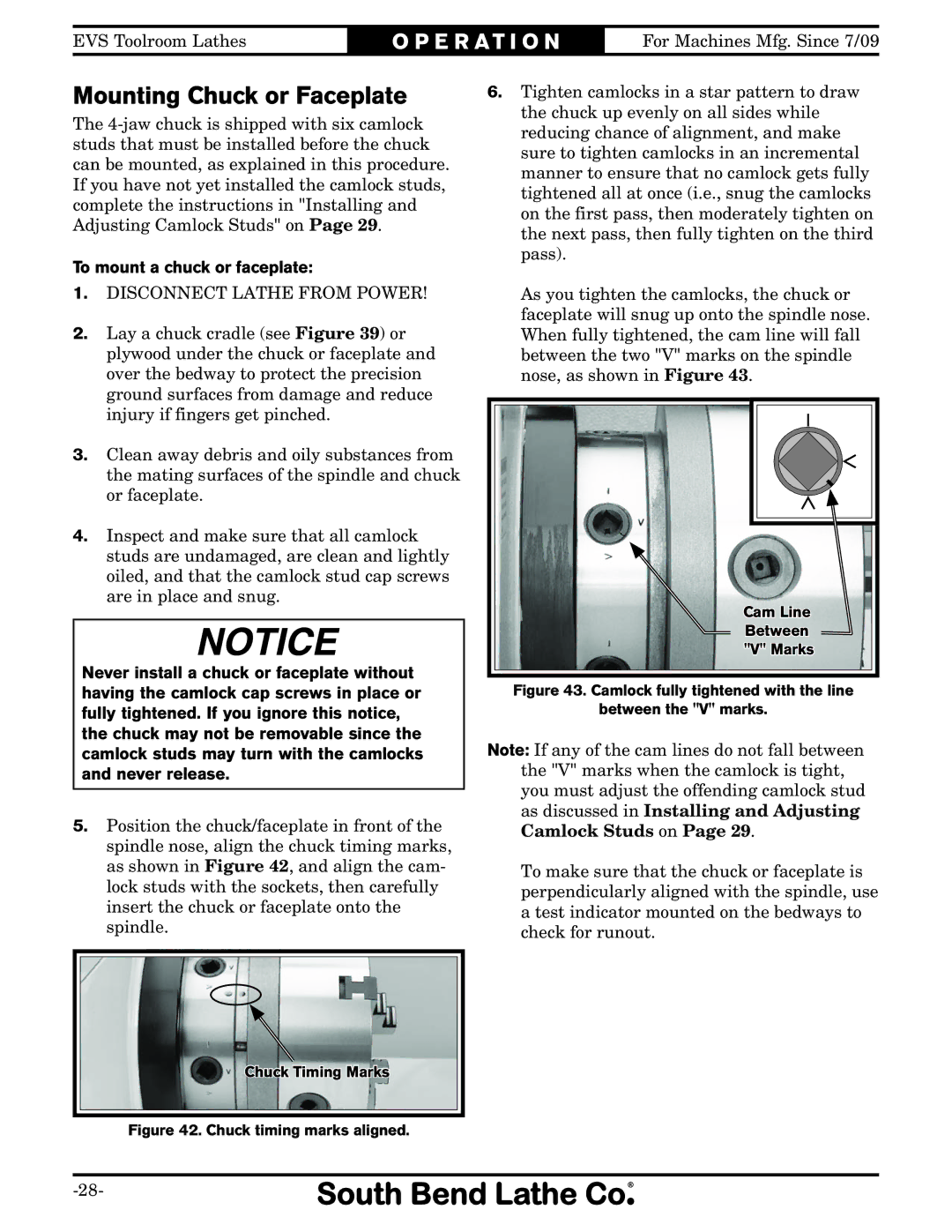

As you tighten the camlocks, the chuck or faceplate will snug up onto the spindle nose. When fully tightened, the cam line will fall between the two "V" marks on the spindle nose, as shown in Figure 43.

Cam Line |

Between |

"V" Marks |

Figure 43. Camlock fully tightened with the line

between the "V" marks.

Note: If any of the cam lines do not fall between the "V" marks when the camlock is tight, you must adjust the offending camlock stud as discussed in Installing and Adjusting Camlock Studs on Page 29.

To make sure that the chuck or faceplate is perpendicularly aligned with the spindle, use a test indicator mounted on the bedways to check for runout.

Chuck Timing Marks