For Machines Mfg. Since 7/09 | O P E R A T I O N | EVS Toolroom Lathes |

Changing Jaws |

|

Item Needed | Qty |

Chuck Key | 1 |

White Lithium Grease | As Needed |

To change the jaw:

1.DISCONNECT LATHE FROM POWER!

2.Place a piece of wood over the ways to protect them from potential damage.

3.Insert the chuck key and turn it counterclockwise to back the jaws out and remove them.

4.Clean the jaw mating surfaces and apply a thin film of white lithium grease to the mating surfaces.

5.Set the previously mounted jaws aside in a safe place free of moisture and abrasives.

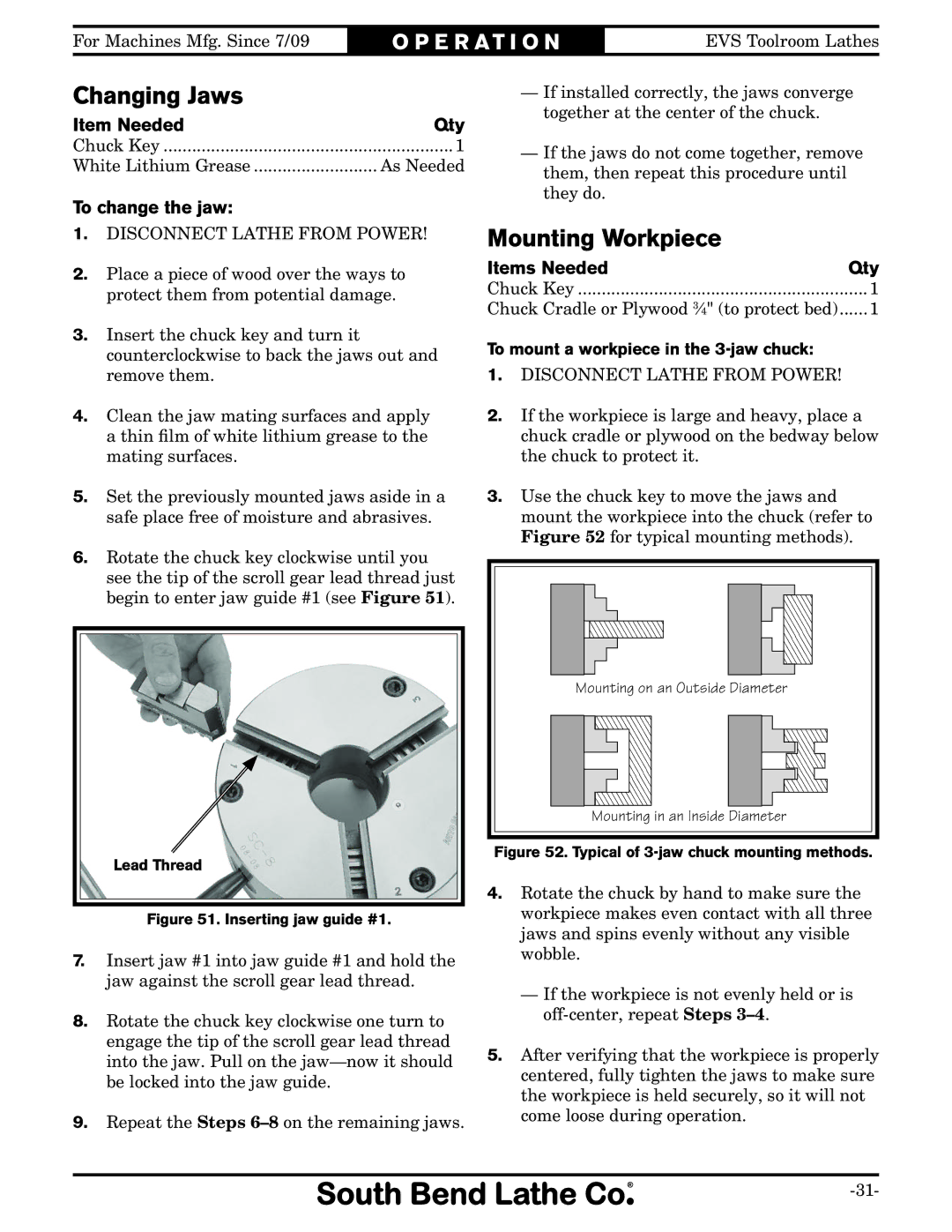

6.Rotate the chuck key clockwise until you see the tip of the scroll gear lead thread just begin to enter jaw guide #1 (see Figure 51).

Lead Thread

Figure 51. Inserting jaw guide #1.

7.Insert jaw #1 into jaw guide #1 and hold the jaw against the scroll gear lead thread.

8.Rotate the chuck key clockwise one turn to engage the tip of the scroll gear lead thread into the jaw. Pull on the

9.Repeat the Steps

—If installed correctly, the jaws converge together at the center of the chuck.

—If the jaws do not come together, remove them, then repeat this procedure until they do.

Mounting Workpiece |

|

Items Needed | Qty |

Chuck Key | 1 |

Chuck Cradle or Plywood 3⁄4" (to protect bed) | 1 |

To mount a workpiece in the 3-jaw chuck:

1.DISCONNECT LATHE FROM POWER!

2.If the workpiece is large and heavy, place a chuck cradle or plywood on the bedway below the chuck to protect it.

3.Use the chuck key to move the jaws and mount the workpiece into the chuck (refer to Figure 52 for typical mounting methods).

Mounting on an Outside Diameter

Mounting in an Inside Diameter

Figure 52. Typical of 3-jaw chuck mounting methods.

4.Rotate the chuck by hand to make sure the workpiece makes even contact with all three jaws and spins evenly without any visible wobble.

—If the workpiece is not evenly held or is

5.After verifying that the workpiece is properly centered, fully tighten the jaws to make sure the workpiece is held securely, so it will not come loose during operation.