For Machines Mfg. Since 7/09 | O P E R A T I O N | EVS Toolroom Lathes |

Steady Rest

The steady rest supports long shafts and can be mounted anywhere along the length of the bed.

To install and use the steady rest:

1.DISCONNECT LATHE FROM POWER!

2.Thoroughly clean the machined base of the steady rest, then place it on the lathe bedways so the triangular notch fits over the bedway prism.

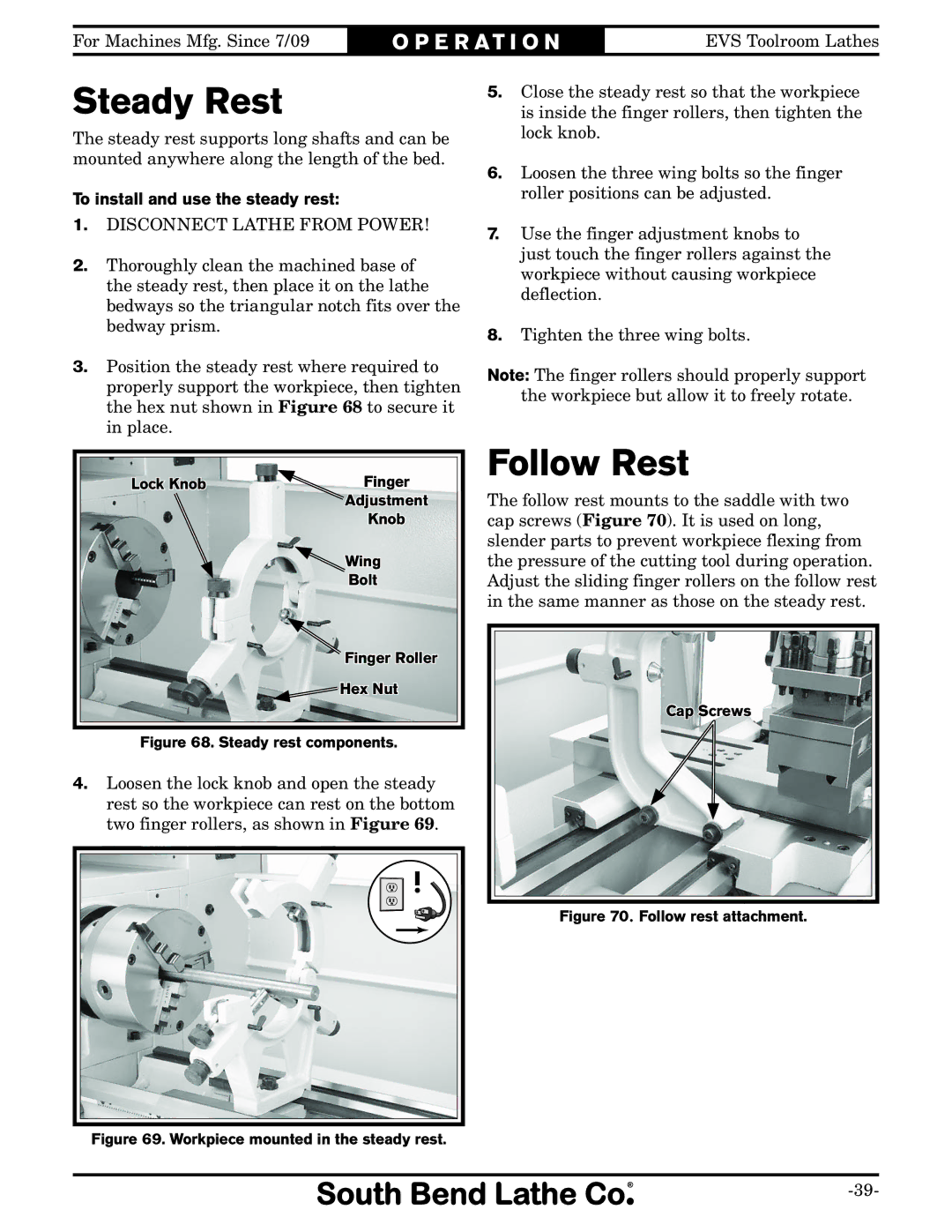

3.Position the steady rest where required to properly support the workpiece, then tighten the hex nut shown in Figure 68 to secure it in place.

Lock Knob | Finger |

Adjustment

Knob

![]() Wing

Wing

Bolt

Finger Roller

![]() Hex Nut

Hex Nut

Figure 68. Steady rest components.

4.Loosen the lock knob and open the steady rest so the workpiece can rest on the bottom two finger rollers, as shown in Figure 69.

!

5.Close the steady rest so that the workpiece is inside the finger rollers, then tighten the lock knob.

6.Loosen the three wing bolts so the finger roller positions can be adjusted.

7.Use the finger adjustment knobs to just touch the finger rollers against the workpiece without causing workpiece deflection.

8.Tighten the three wing bolts.

Note: The finger rollers should properly support the workpiece but allow it to freely rotate.

Follow Rest

The follow rest mounts to the saddle with two cap screws (Figure 70). It is used on long, slender parts to prevent workpiece flexing from the pressure of the cutting tool during operation. Adjust the sliding finger rollers on the follow rest in the same manner as those on the steady rest.

Cap Screws