For Machines Mfg. Since 7/09 | O P E R A T I O N | EVS Toolroom Lathes |

Note: As long as this dead center remains in the chuck, the point of the center will remain true to the spindle center line. The point will have to be refinished whenever the center is removed and then returned to the chuck.

5.Install a center in the tailstock.

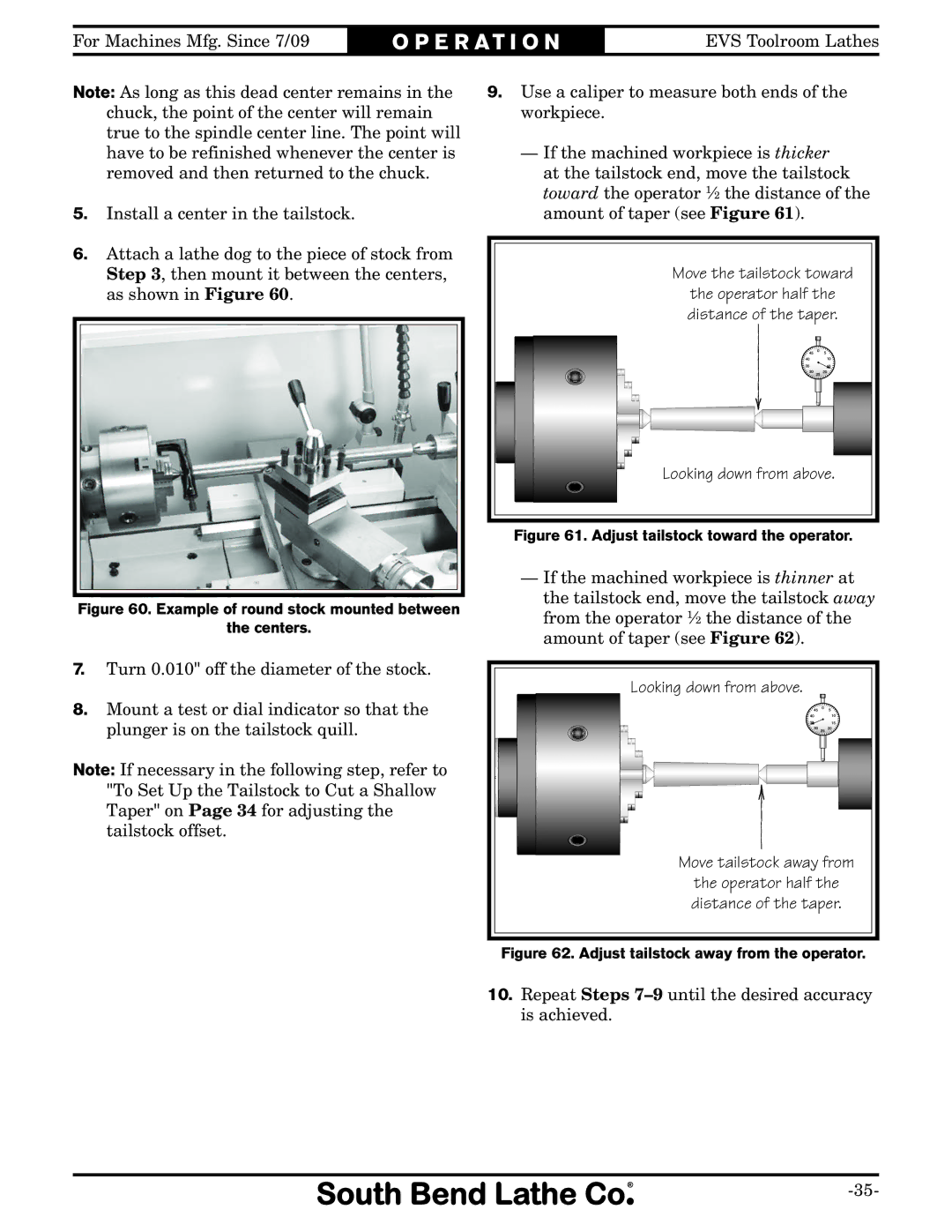

6.Attach a lathe dog to the piece of stock from Step 3, then mount it between the centers, as shown in Figure 60.

Figure 60. Example of round stock mounted between

the centers.

7.Turn 0.010" off the diameter of the stock.

8.Mount a test or dial indicator so that the plunger is on the tailstock quill.

Note: If necessary in the following step, refer to "To Set Up the Tailstock to Cut a Shallow Taper" on Page 34 for adjusting the tailstock offset.

9.Use a caliper to measure both ends of the workpiece.

—If the machined workpiece is thicker at the tailstock end, move the tailstock toward the operator 1⁄2 the distance of the amount of taper (see Figure 61).

Move the tailstock toward |

the operator half the |

distance of the taper. |

Looking down from above. |

Figure 61. Adjust tailstock toward the operator.

—If the machined workpiece is thinner at the tailstock end, move the tailstock away from the operator 1⁄2 the distance of the amount of taper (see Figure 62).

Looking down from above. |

Move tailstock away from |

the operator half the |

distance of the taper. |

Figure 62. Adjust tailstock away from the operator.

10.Repeat Steps