For Machines Mfg. Since 7/09 | P R E P A R A T I O N | EVS Toolroom Lathes |

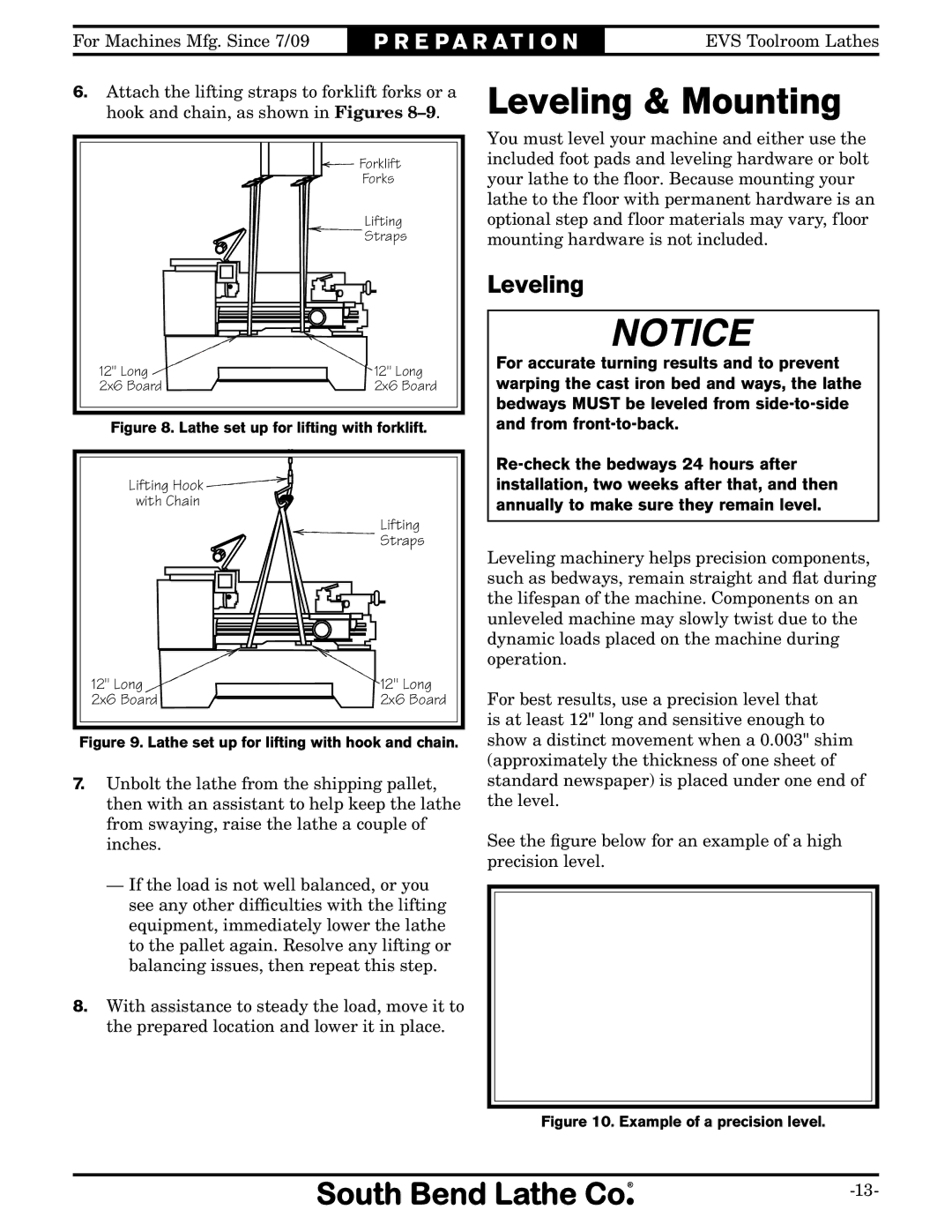

6.Attach the lifting straps to forklift forks or a hook and chain, as shown in Figures

![]() Forklift

Forklift

Forks

Lifting

Straps

12" Long | 12" Long |

2x6 Board | 2x6 Board |

Figure 8. Lathe set up for lifting with forklift.

Lifting Hook ![]()

![]()

with Chain

Lifting

Straps

12" Long | 12" Long |

2x6 Board | 2x6 Board |

Figure 9. Lathe set up for lifting with hook and chain.

7.Unbolt the lathe from the shipping pallet, then with an assistant to help keep the lathe from swaying, raise the lathe a couple of inches.

—If the load is not well balanced, or you see any other difficulties with the lifting equipment, immediately lower the lathe to the pallet again. Resolve any lifting or balancing issues, then repeat this step.

8.With assistance to steady the load, move it to the prepared location and lower it in place.

Leveling & Mounting

You must level your machine and either use the included foot pads and leveling hardware or bolt your lathe to the floor. Because mounting your lathe to the floor with permanent hardware is an optional step and floor materials may vary, floor mounting hardware is not included.

Leveling

For accurate turning results and to prevent warping the cast iron bed and ways, the lathe bedways MUST be leveled from

Leveling machinery helps precision components, such as bedways, remain straight and flat during the lifespan of the machine. Components on an unleveled machine may slowly twist due to the dynamic loads placed on the machine during operation.

For best results, use a precision level that is at least 12" long and sensitive enough to show a distinct movement when a 0.003" shim (approximately the thickness of one sheet of standard newspaper) is placed under one end of the level.

See the figure below for an example of a high precision level.