EVS Toolroom Lathes | P R E P A R A T I O N | For Machines Mfg. Since 7/09 |

Lifting & Moving

This machine and its parts are heavy! Serious personal injury may occur if safe moving methods are not used. To reduce the risk of a lifting or dropping injury, ask others for help and use power equipment.

Do not attempt to lift or move this lathe if you do not have the proper equipment or the necessary assistance from other people. All lifting equipment must be rated to at least 5,000 lbs. to account for dynamic loads from bouncing or pulling that may be applied while lifting. Refer to the Things You'll Need section on Page 8 for details.

To lift and move your lathe:

1.Prepare the permanent location for the lathe.

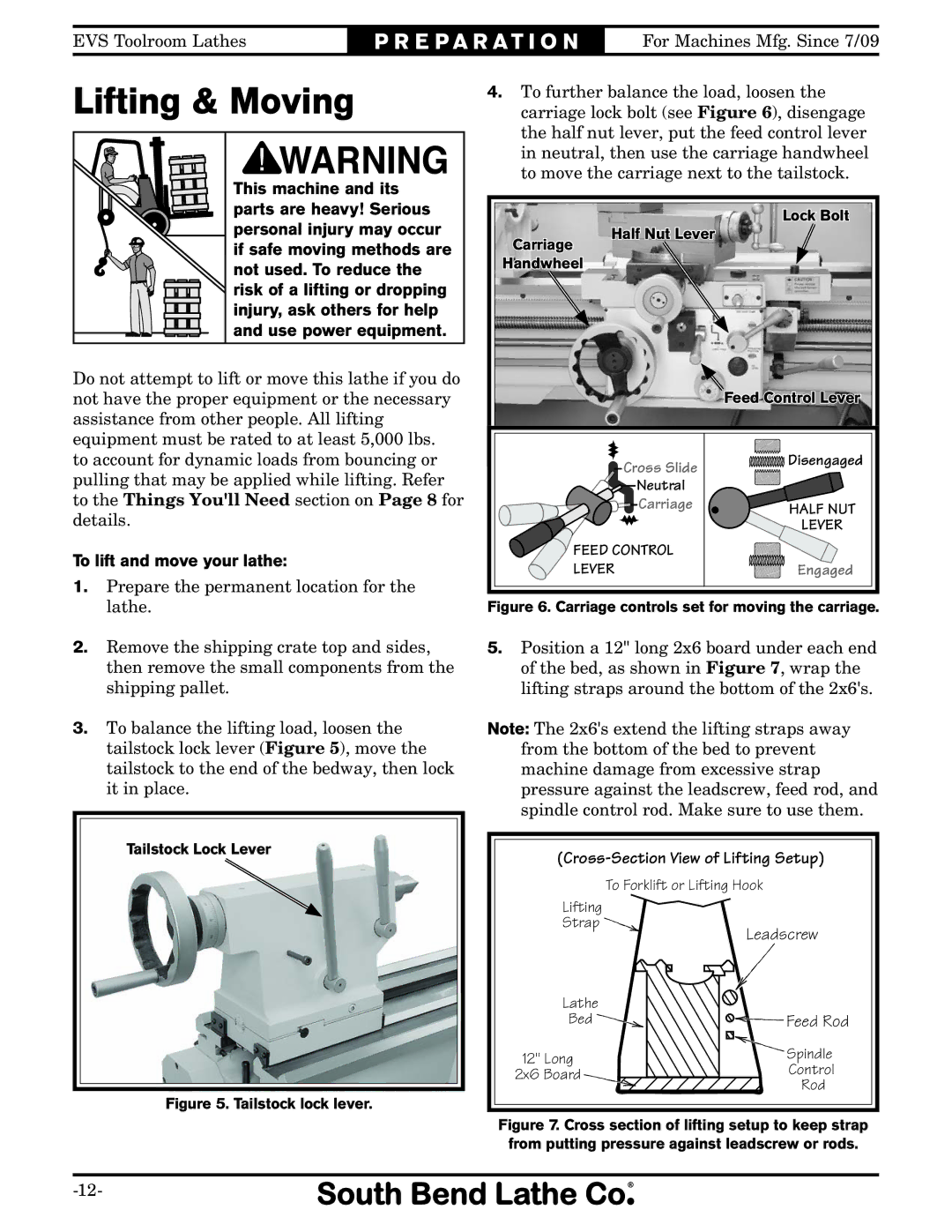

4.To further balance the load, loosen the carriage lock bolt (see Figure 6), disengage the half nut lever, put the feed control lever in neutral, then use the carriage handwheel to move the carriage next to the tailstock.

Half Nut Lever | Lock Bolt |

| |

Carriage |

|

Handwheel |

|

| Feed Control Lever |

Cross Slide | Disengaged |

| |

Neutral |

|

Carriage | HALF NUT |

| LEVER |

FEED CONTROL |

|

LEVER | Engaged |

Figure 6. Carriage controls set for moving the carriage.

2.Remove the shipping crate top and sides, then remove the small components from the shipping pallet.

3.To balance the lifting load, loosen the tailstock lock lever (Figure 5), move the tailstock to the end of the bedway, then lock it in place.

Tailstock Lock Lever

Figure 5. Tailstock lock lever.

5.Position a 12" long 2x6 board under each end of the bed, as shown in Figure 7, wrap the lifting straps around the bottom of the 2x6's.

Note: The 2x6's extend the lifting straps away

from the bottom of the bed to prevent machine damage from excessive strap pressure against the leadscrew, feed rod, and spindle control rod. Make sure to use them.

(Cross-Section View of Lifting Setup)

| To Forklift or Lifting Hook | |

Lifting |

| |

Strap | Leadscrew | |

| ||

Lathe |

| |

Bed | Feed Rod | |

12" Long | Spindle | |

Control | ||

2x6 Board | ||

Rod | ||

|