For Machines Mfg. Since 7/09 | O P E R A T I O N | EVS Toolroom Lathes |

Moving Along Bedway

1.Pull the tailstock lock lever backward (away from the spindle) to unlock the tailstock from the bedway.

2.Slide the tailstock to the desired position.

3.Push the tailstock lock lever forward (toward the spindle) to lock the tailstock to the bedway.

Using Quill

1.Release the quill lock lever.

2.Turn the quill handwheel clockwise to move the quill towards the spindle, or turn counterclockwise to move the quill away from the spindle.

3.Push the quill lock forward to lock the quill in place.

To install tooling in the tailstock:

1.With the tailstock locked in place, unlock the quill, then use the handwheel to extend it to the 1" mark on the quill.

2.Insert the drill chuck arbor or drill shank into the quill, then quickly slap it in. Try to twist the tool to check if it is firmly seated. A firmly seated taper will not twist.

Note: If the tapered shaft has a tang, align it horizontally with the indent in the back of the quill before fully inserting it.

3.Unlock the tailstock and move it until the tip of the cutting tool is close to, but not touching, the workpiece, then

4.Start spindle rotation, unlock the quill, then turn the quill handwheel clockwise to feed the cutting tool into the workpiece.

Installing Tooling

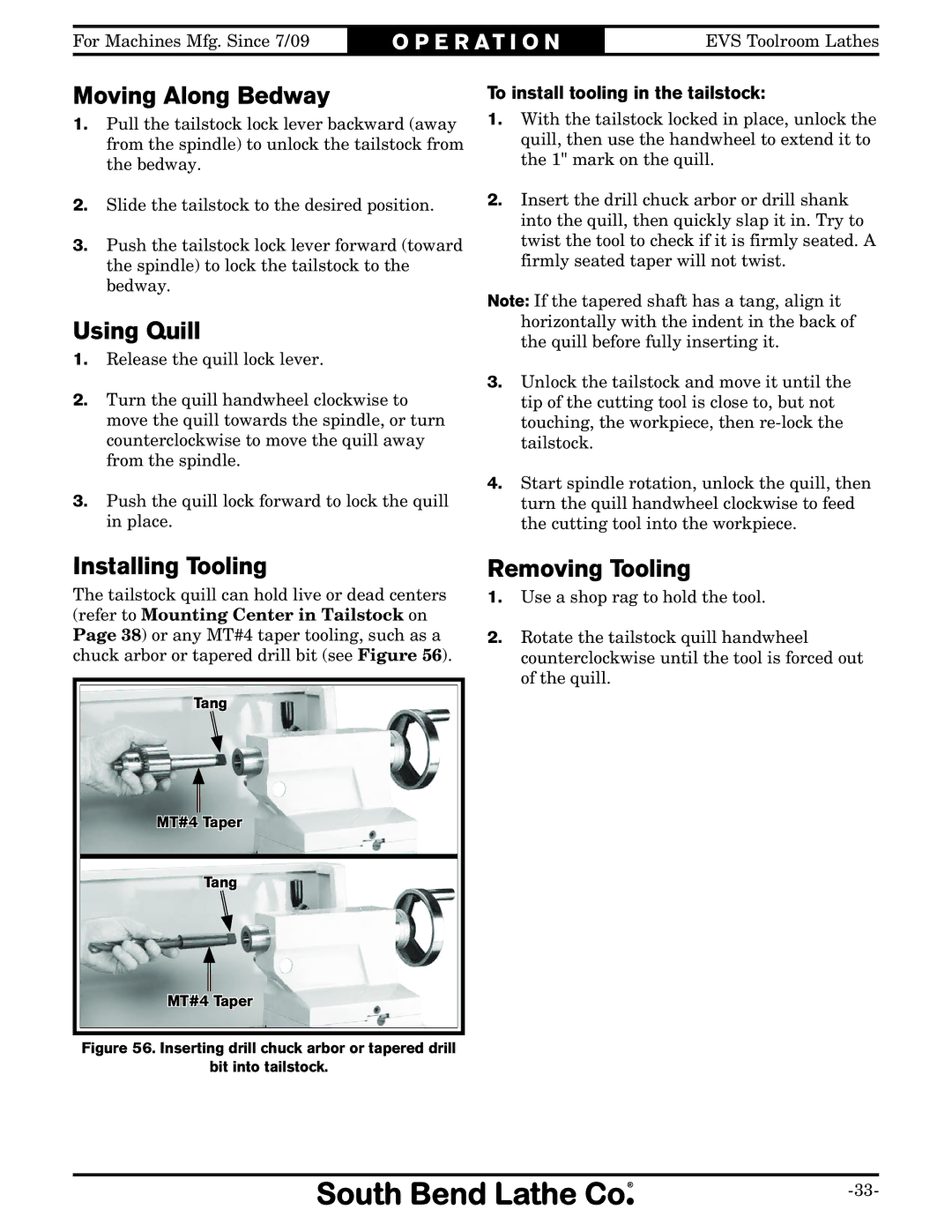

The tailstock quill can hold live or dead centers (refer to Mounting Center in Tailstock on Page 38) or any MT#4 taper tooling, such as a chuck arbor or tapered drill bit (see Figure 56).

Tang

MT#4 Taper

Tang

MT#4 Taper

Figure 56. Inserting drill chuck arbor or tapered drill

bit into tailstock.

Removing Tooling

1.Use a shop rag to hold the tool.

2.Rotate the tailstock quill handwheel counterclockwise until the tool is forced out of the quill.