For Machines Mfg. Since 7/09 | O P E R A T I O N | EVS Toolroom Lathes |

Installing and Adjusting Camlock Studs

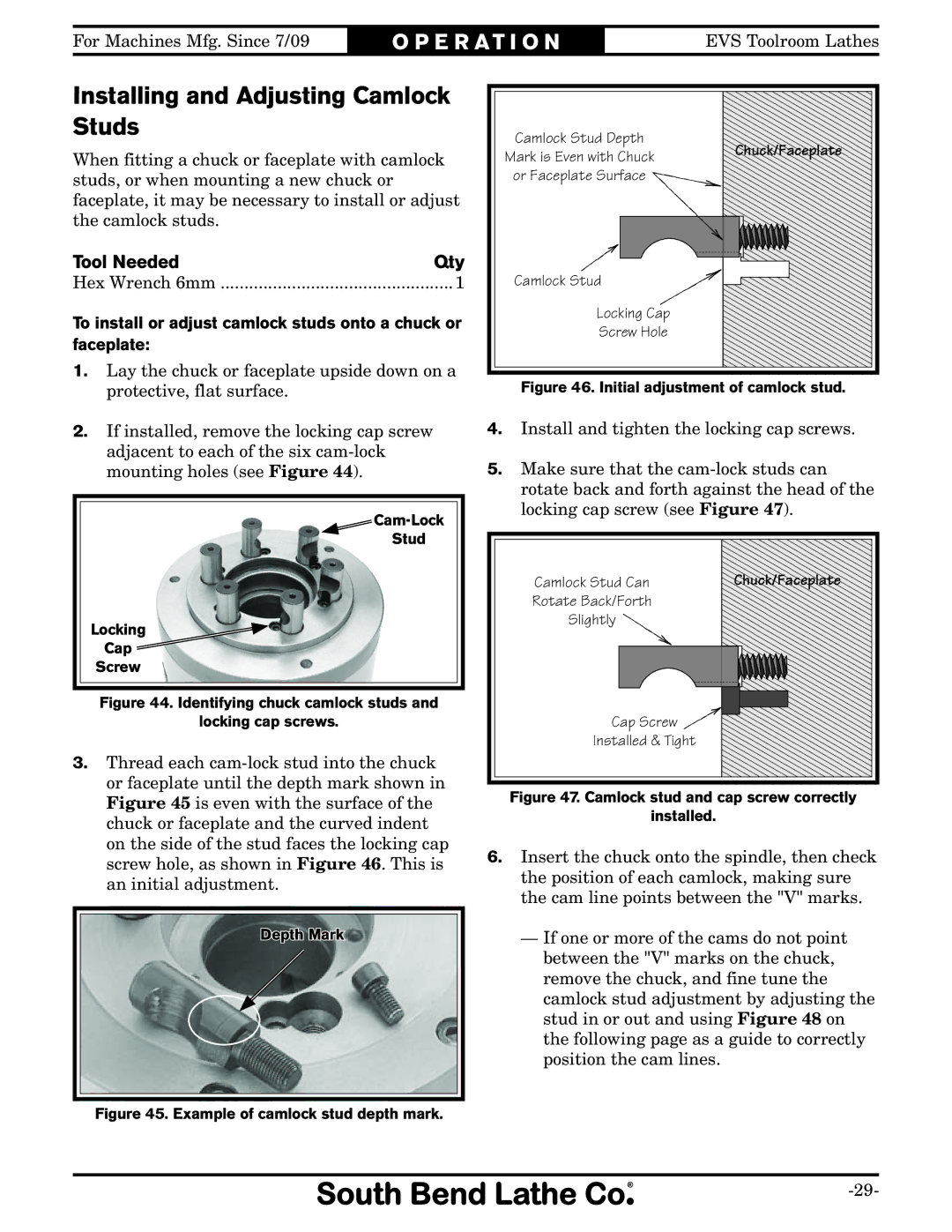

When fitting a chuck or faceplate with camlock studs, or when mounting a new chuck or faceplate, it may be necessary to install or adjust the camlock studs.

Tool Needed | Qty |

Hex Wrench 6mm | ................................................. 1 |

To install or adjust camlock studs onto a chuck or faceplate:

1.Lay the chuck or faceplate upside down on a protective, flat surface.

2.If installed, remove the locking cap screw adjacent to each of the six

![]()

Stud

Locking

Cap

Screw

Figure 44. Identifying chuck camlock studs and

locking cap screws.

3.Thread each

Depth Mark

Figure 45. Example of camlock stud depth mark.

Camlock Stud Depth

Mark is Even with ChuckChuck/Faceplate or Faceplate Surface ![]()

Camlock Stud

Locking Cap

Screw Hole

Figure 46. Initial adjustment of camlock stud.

4.Install and tighten the locking cap screws.

5.Make sure that the

Camlock Stud Can | Chuck/Faceplate |

Rotate Back/Forth |

|

Slightly |

|

Cap Screw ![]()

Installed & Tight

Figure 47. Camlock stud and cap screw correctly

installed.

6.Insert the chuck onto the spindle, then check the position of each camlock, making sure the cam line points between the "V" marks.

—If one or more of the cams do not point between the "V" marks on the chuck, remove the chuck, and fine tune the camlock stud adjustment by adjusting the stud in or out and using Figure 48 on the following page as a guide to correctly position the cam lines.