EVS Toolroom Lathes | O P E R A T I O N | For Machines Mfg. Since 7/09 |

| 6. After the workpiece is held in place by | |

the jaws, turn the chuck by hand and pay | ||

Refer to Chuck & Faceplate Mounting | attention to the workpiece alignment. | |

| ||

instructions on Page 27 to mount the | — If the workpiece is not correctly aligned | |

chuck to the spindle. | ||

for your operation as you turn the chuck, | ||

| ||

The | make fine adjustments by slightly | |

loosening one jaw and tightening the | ||

adjustable hardened steel jaws to hold non- | ||

opposing jaw until the workpiece is | ||

cylindrical or | ||

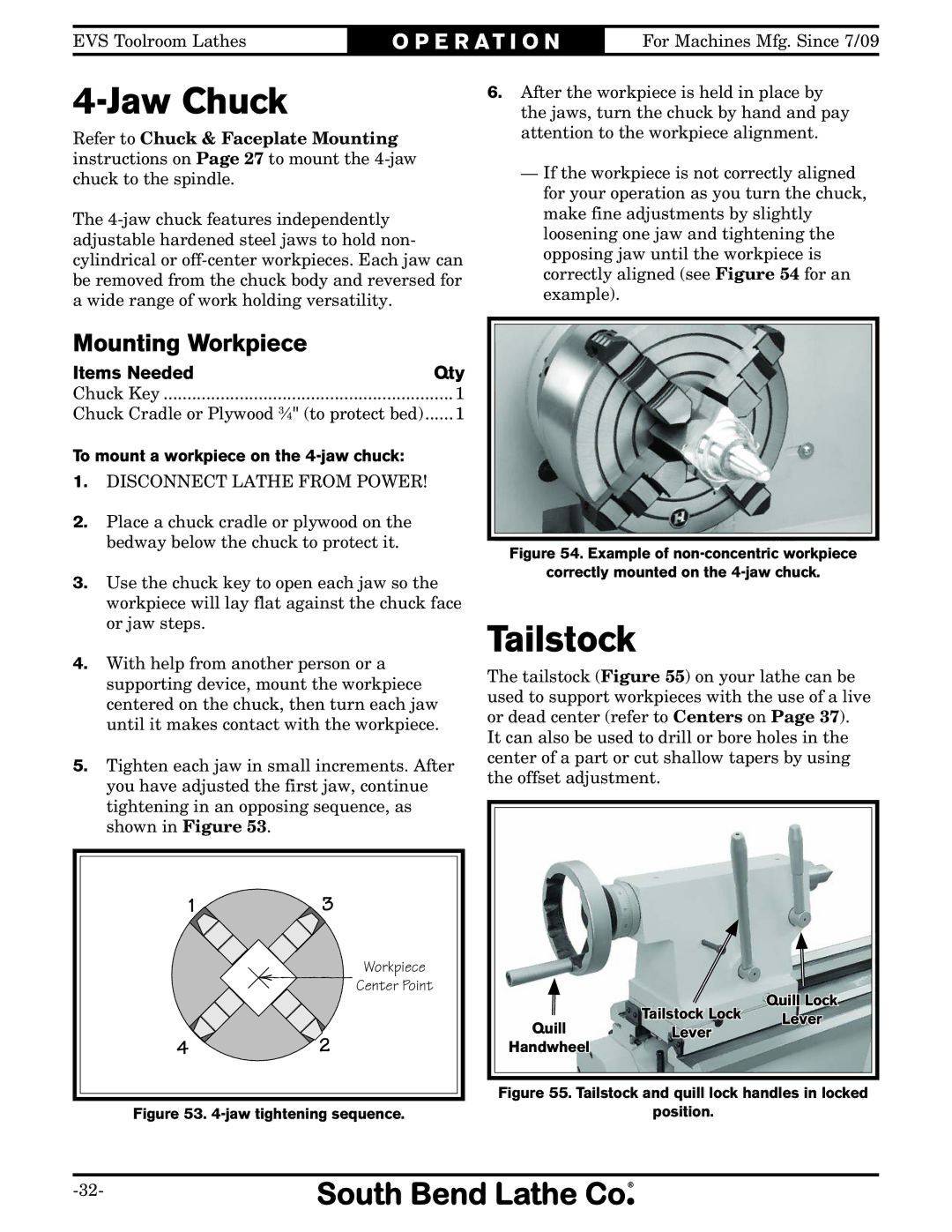

correctly aligned (see Figure 54 for an | ||

be removed from the chuck body and reversed for | ||

example). | ||

a wide range of work holding versatility. | ||

|

Mounting Workpiece |

|

Items Needed | Qty |

Chuck Key | 1 |

Chuck Cradle or Plywood 3⁄4" (to protect bed) | 1 |

To mount a workpiece on the 4-jaw chuck:

1.DISCONNECT LATHE FROM POWER!

2.Place a chuck cradle or plywood on the bedway below the chuck to protect it.

3.Use the chuck key to open each jaw so the workpiece will lay flat against the chuck face or jaw steps.

4.With help from another person or a supporting device, mount the workpiece centered on the chuck, then turn each jaw until it makes contact with the workpiece.

5.Tighten each jaw in small increments. After you have adjusted the first jaw, continue tightening in an opposing sequence, as shown in Figure 53.

13

Workpiece

Center Point

42

Figure 53. 4-jaw tightening sequence.

Figure 54. Example of non-concentric workpiece

correctly mounted on the 4-j

aw

aw chuck.

Tailstock

The tailstock (Figure 55) on your lathe can be used to support workpieces with the use of a live or dead center (refer to Centers on Page 37). It can also be used to drill or bore holes in the center of a part or cut shallow tapers by using the offset adjustment.

| Tailstock Lock | Quill Lock | |

Quill | Lever | ||

Lever | |||

|

H![]()

![]() andwheel

andwheel