For Machines Mfg. Since 7/09 | O P E R A T I O N | EVS Toolroom Lathes |

End Gear Setup

The gearbox drive gear on this lathe can be configured for the "normal position" or the "alternate position" (both described in following paragraphs), depending upon the type of operation to be performed. The lathe is shipped with the end gears in the normal position. Gears must be thoroughly cleaned and

Normal Position

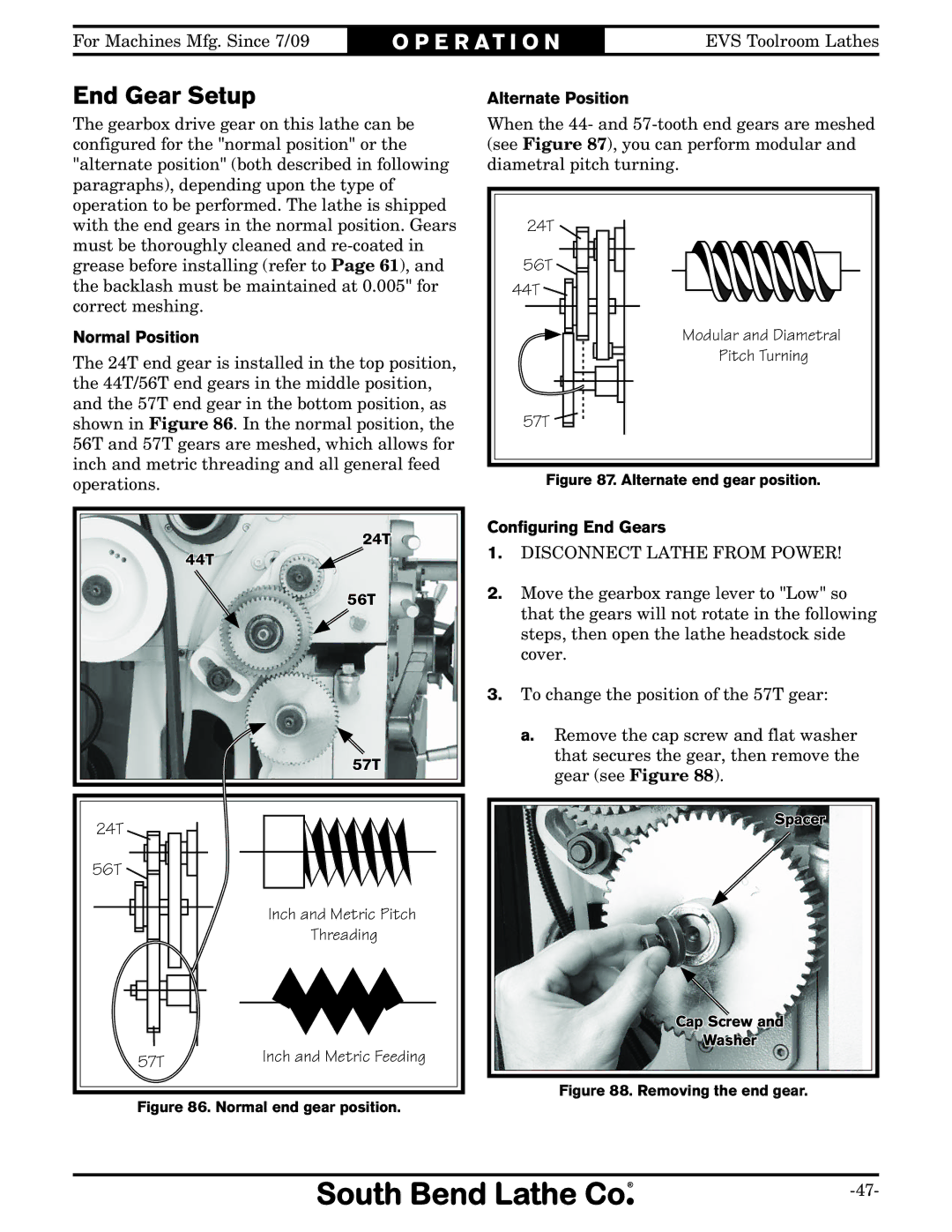

The 24T end gear is installed in the top position, the 44T/56T end gears in the middle position, and the 57T end gear in the bottom position, as shown in Figure 86. In the normal position, the 56T and 57T gears are meshed, which allows for inch and metric threading and all general feed operations.

Alternate Position

When the 44- and

24T |

56T |

44T |

Modular and Diametral |

Pitch Turning |

57T |

Figure 87. Alternate end gear position.

24T

44T

56T

| 57T |

24T |

|

56T |

|

| Inch and Metric Pitch |

| Threading |

57T | Inch and Metric Feeding |

|

Figure 86. Normal end gear position.

Configuring End Gears

1.DISCONNECT LATHE FROM POWER!

2.Move the gearbox range lever to "Low" so that the gears will not rotate in the following steps, then open the lathe headstock side cover.

3.To change the position of the 57T gear:

a.Remove the cap screw and flat washer that secures the gear, then remove the gear (see Figure 88).

Spacer

Cap Screw and

Washer