All installations and services must be performed by qualified service personnel.

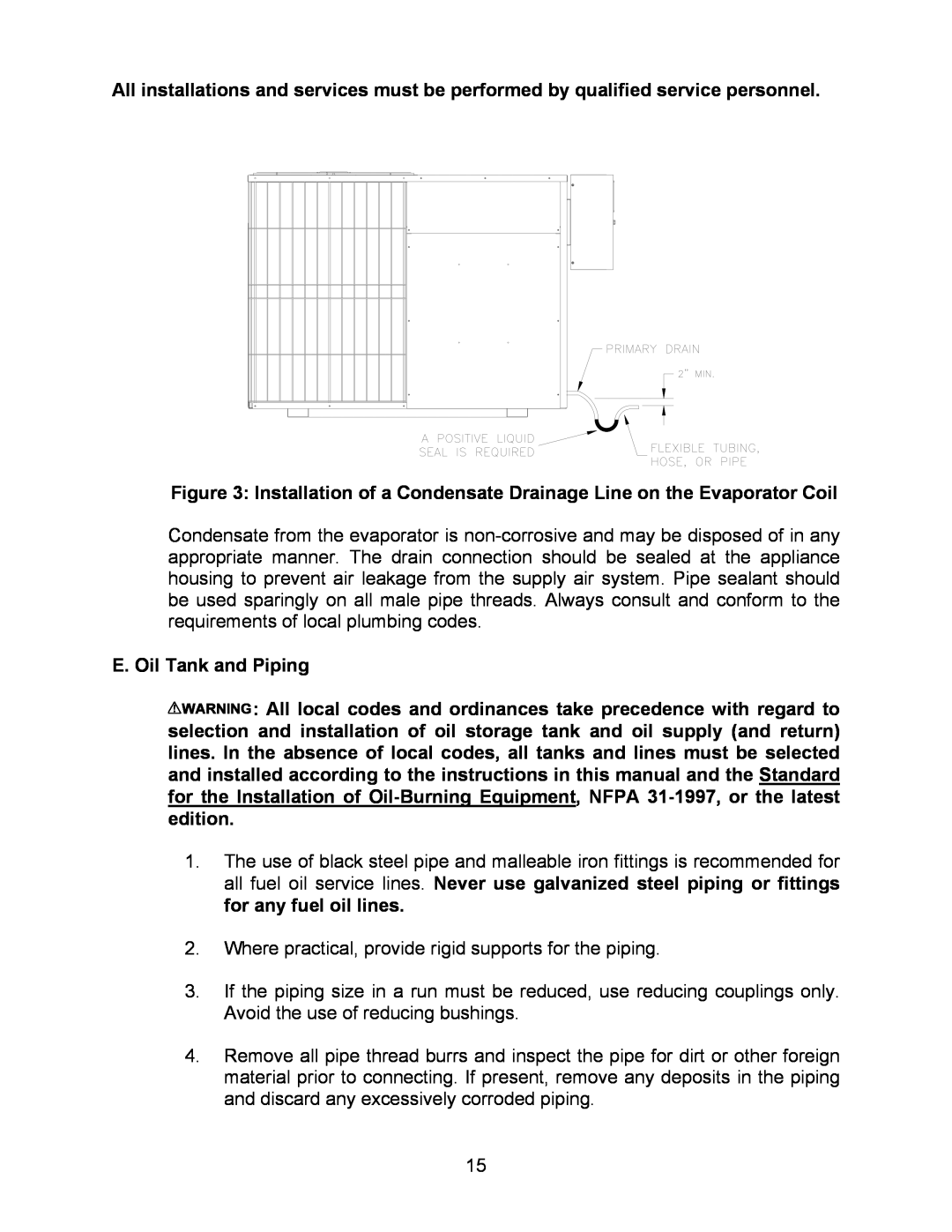

Figure 3: Installation of a Condensate Drainage Line on the Evaporator Coil

Condensate from the evaporator is

E. Oil Tank and Piping

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() : All local codes and ordinances take precedence with regard to selection and installation of oil storage tank and oil supply (and return) lines. In the absence of local codes, all tanks and lines must be selected and installed according to the instructions in this manual and the Standard for the Installation of

: All local codes and ordinances take precedence with regard to selection and installation of oil storage tank and oil supply (and return) lines. In the absence of local codes, all tanks and lines must be selected and installed according to the instructions in this manual and the Standard for the Installation of

1.The use of black steel pipe and malleable iron fittings is recommended for all fuel oil service lines. Never use galvanized steel piping or fittings for any fuel oil lines.

2.Where practical, provide rigid supports for the piping.

3.If the piping size in a run must be reduced, use reducing couplings only. Avoid the use of reducing bushings.

4.Remove all pipe thread burrs and inspect the pipe for dirt or other foreign material prior to connecting. If present, remove any deposits in the piping and discard any excessively corroded piping.

15