All installations and services must be performed by qualified service personnel.

The pressure drops for the remaining branches of the system must be set. This includes segment “G”; segments “I” and “J”; and segments “K”, “L”, and “M”. To balance the system, the pressure drop for each branch must be approximately equal to the pressure drops of the other branches. For example, segment “G” must equal segments “D”, “E” and “F” combined. Thus,

ΔPG = ΔPD + ΔPE + ΔPF .

Likewise for the other branches,

ΔPI + ΔPJ = 0.1 in. W.G.

ΔPK + ΔPl + ΔPm = 0.1 in. W.G. .

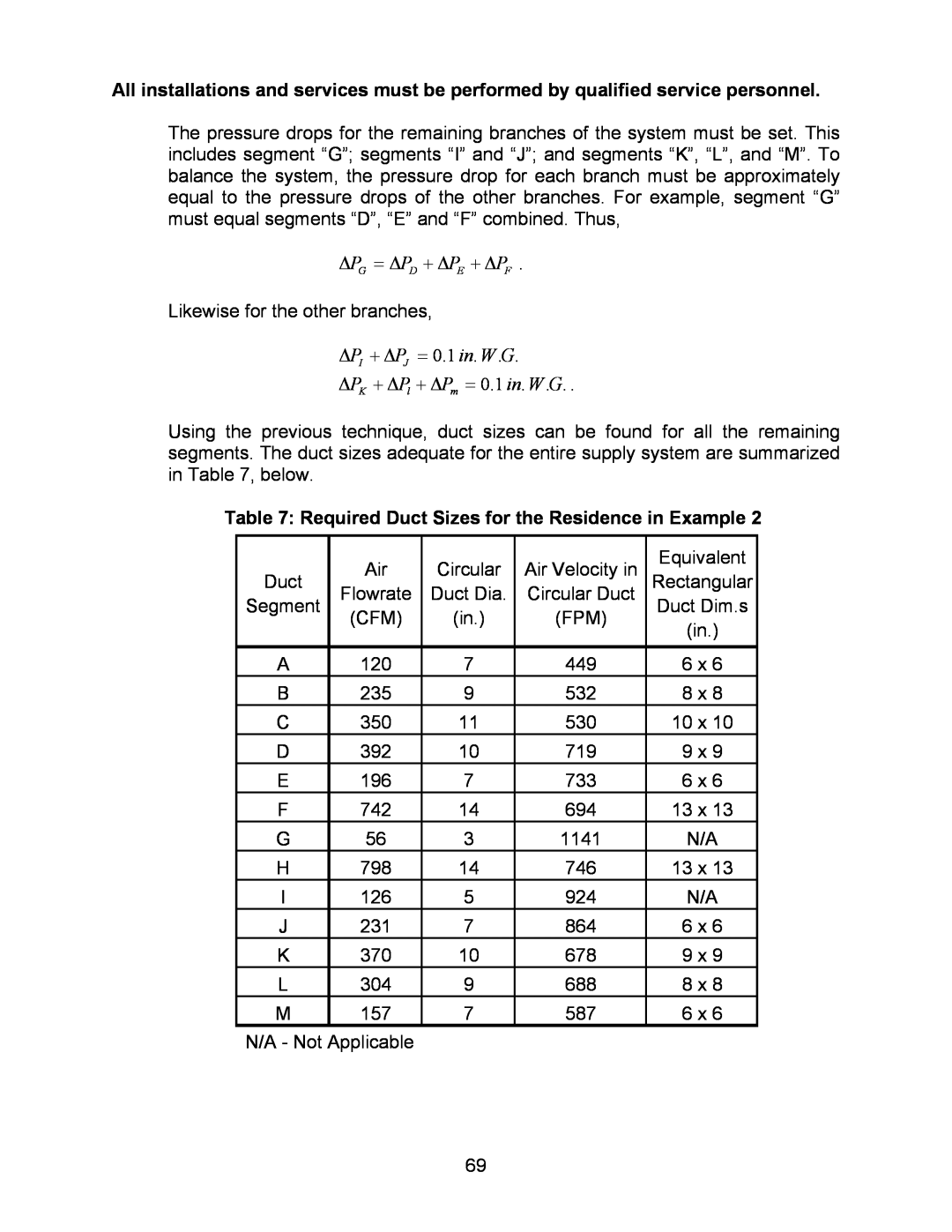

Using the previous technique, duct sizes can be found for all the remaining segments. The duct sizes adequate for the entire supply system are summarized in Table 7, below.

Table 7: Required Duct Sizes for the Residence in Example 2

| Air | Circular | Air Velocity in | Equivalent |

Duct | Rectangular | |||

Segment | Flowrate | Duct Dia. | Circular Duct | Duct Dim.s |

| (CFM) | (in.) | (FPM) | (in.) |

|

|

|

| |

|

|

|

|

|

A | 120 | 7 | 449 | 6 x 6 |

B | 235 | 9 | 532 | 8 x 8 |

C | 350 | 11 | 530 | 10 x 10 |

D | 392 | 10 | 719 | 9 x 9 |

E | 196 | 7 | 733 | 6 x 6 |

F | 742 | 14 | 694 | 13 x 13 |

G | 56 | 3 | 1141 | N/A |

H | 798 | 14 | 746 | 13 x 13 |

I | 126 | 5 | 924 | N/A |

J | 231 | 7 | 864 | 6 x 6 |

K | 370 | 10 | 678 | 9 x 9 |

L | 304 | 9 | 688 | 8 x 8 |

M | 157 | 7 | 587 | 6 x 6 |

N/A - Not Applicable

69