All installations and services must be performed by qualified service personnel.

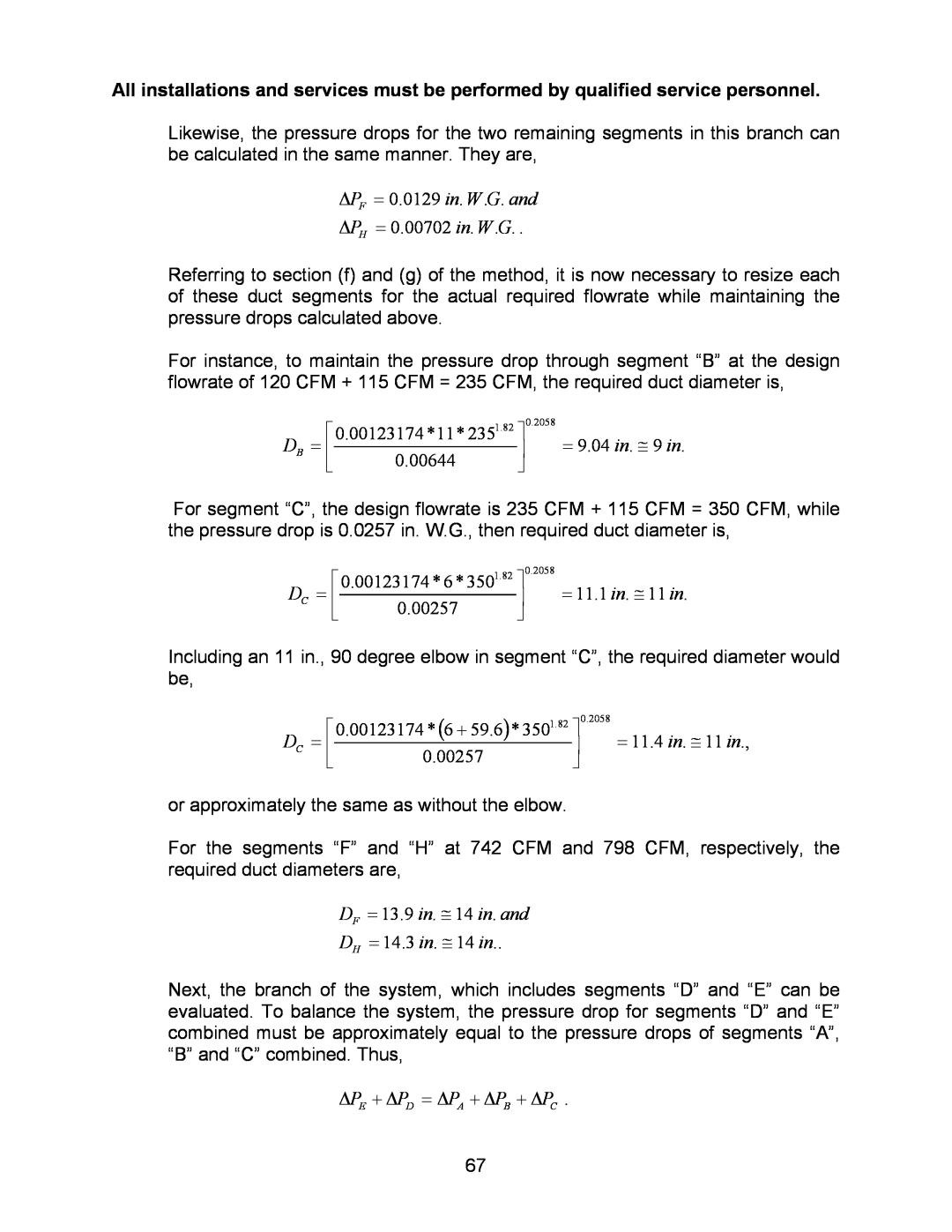

Likewise, the pressure drops for the two remaining segments in this branch can be calculated in the same manner. They are,

ΔPF = 0.0129 in. W.G. and ΔPH = 0.00702 in. W.G. .

Referring to section (f) and (g) of the method, it is now necessary to resize each of these duct segments for the actual required flowrate while maintaining the pressure drops calculated above.

For instance, to maintain the pressure drop through segment “B” at the design flowrate of 120 CFM + 115 CFM = 235 CFM, the required duct diameter is,

| ⎡ | 1.82 | ⎤ | 0.2058 |

D | = ⎢ | 0.00123174 *11* 235 | ⎥ | = 9.04 in. ≅ 9 in. |

| ||||

B | ⎣ | 0.00644 | ⎦ |

|

|

|

For segment “C”, the design flowrate is 235 CFM + 115 CFM = 350 CFM, while the pressure drop is 0.0257 in. W.G., then required duct diameter is,

| ⎡ | 1.82 | ⎤ | 0.2058 |

D | = ⎢ | 0.00123174 * 6 * 350 | ⎥ | = 11.1 in. ≅ 11 in. |

| ||||

C | ⎣ | 0.00257 | ⎦ |

|

|

|

Including an 11 in., 90 degree elbow in segment “C”, the required diameter would be,

| ⎡ | 1.82 | ⎤ | 0.2058 |

D | = ⎢ | 0.00123174 * (6 + 59.6)* 350 | ⎥ | = 11.4 in. ≅ 11 in., |

| ||||

C | ⎣ | 0.00257 | ⎦ |

|

|

|

or approximately the same as without the elbow.

For the segments “F” and “H” at 742 CFM and 798 CFM, respectively, the required duct diameters are,

DF = 13.9 in. ≅ 14 in. and

DH = 14.3 in. ≅ 14 in..

Next, the branch of the system, which includes segments “D” and “E” can be evaluated. To balance the system, the pressure drop for segments “D” and “E” combined must be approximately equal to the pressure drops of segments “A”, “B” and “C” combined. Thus,

ΔPE + ΔPD = ΔPA + ΔPB + ΔPC .

67