| period two |

|

| |

|

| |||

notes |

|

|

| |

|

|

| ||

effects. System effects include | ||||

variations, and variation in distribution system flow. | ||||

| There are benefits to maintaining a constant water flow rate through the chiller | |||

| evaporator. Constant flow provides | |||

| operation. However, there is potential for energy savings by varying the water | |||

| flow in the distribution system. Applying these two | |||

| principles to | |||

| understanding of hydraulic system operation. | |||

| Due to advances in technology, however, many of today’s chillers can operate | |||

| with variable evaporator water flow. | |||

| designed to vary evaporator water flow are discussed in Period Three. This | |||

| period focuses on systems that employ constant water flow through the chiller | |||

| and either constant or variable water flow through the rest of the distribution | |||

| system. |

|

| |

|

|

|

| |

|

| |||

|

|

|

| |

|

| chiller |

|

|

|

| pump | coil | |

|

|

|

| |

Figure 39 |

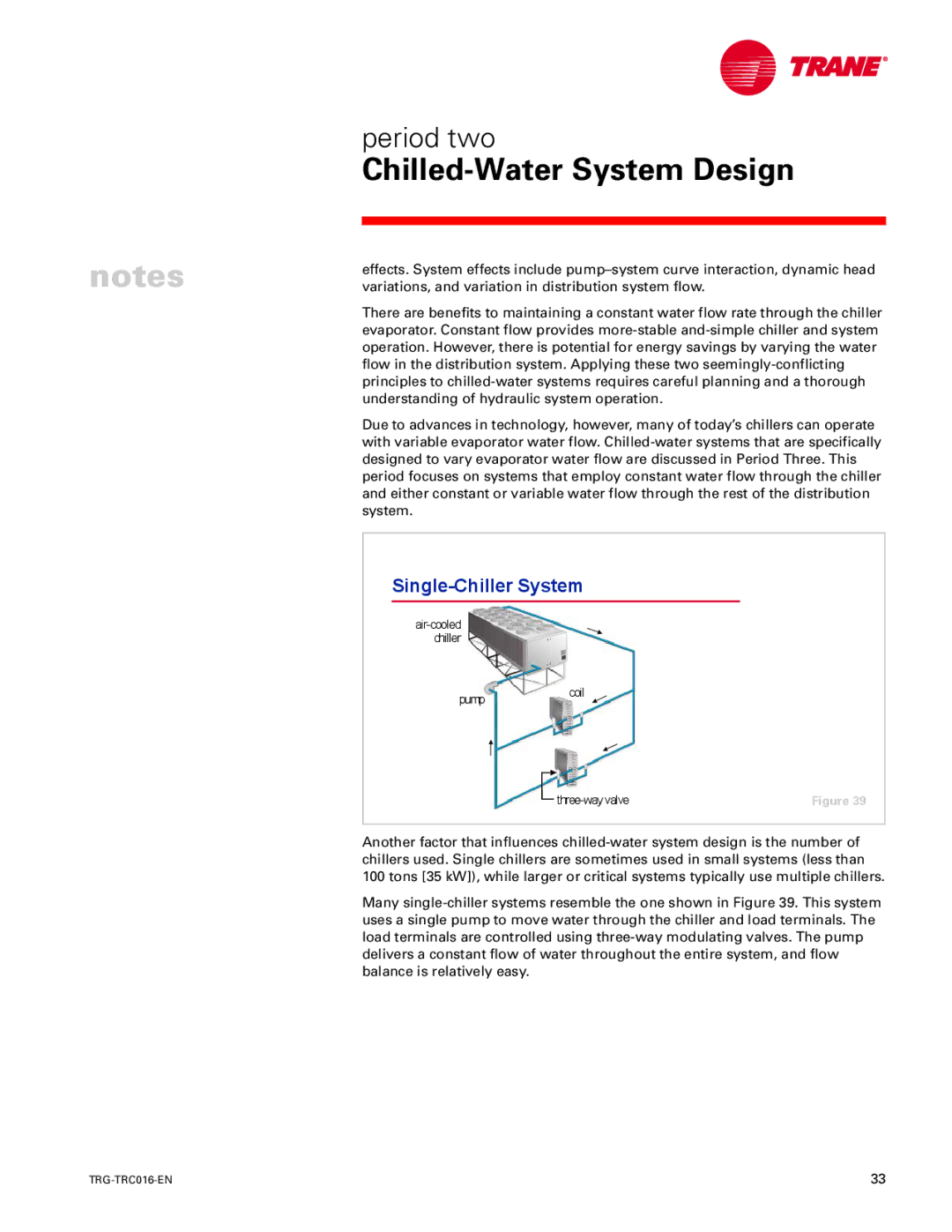

Another factor that influences

Many

33 |