period two

Chilled-Water System Design

notes

chillers piped in parallel

Single Pump

54°F

off[12.2°C]

42°F

42°F  48°F

48°F

on [5.6°C] [8.9°C]

54°F

[12.2°C]

Figure 41

Parallel Configuration

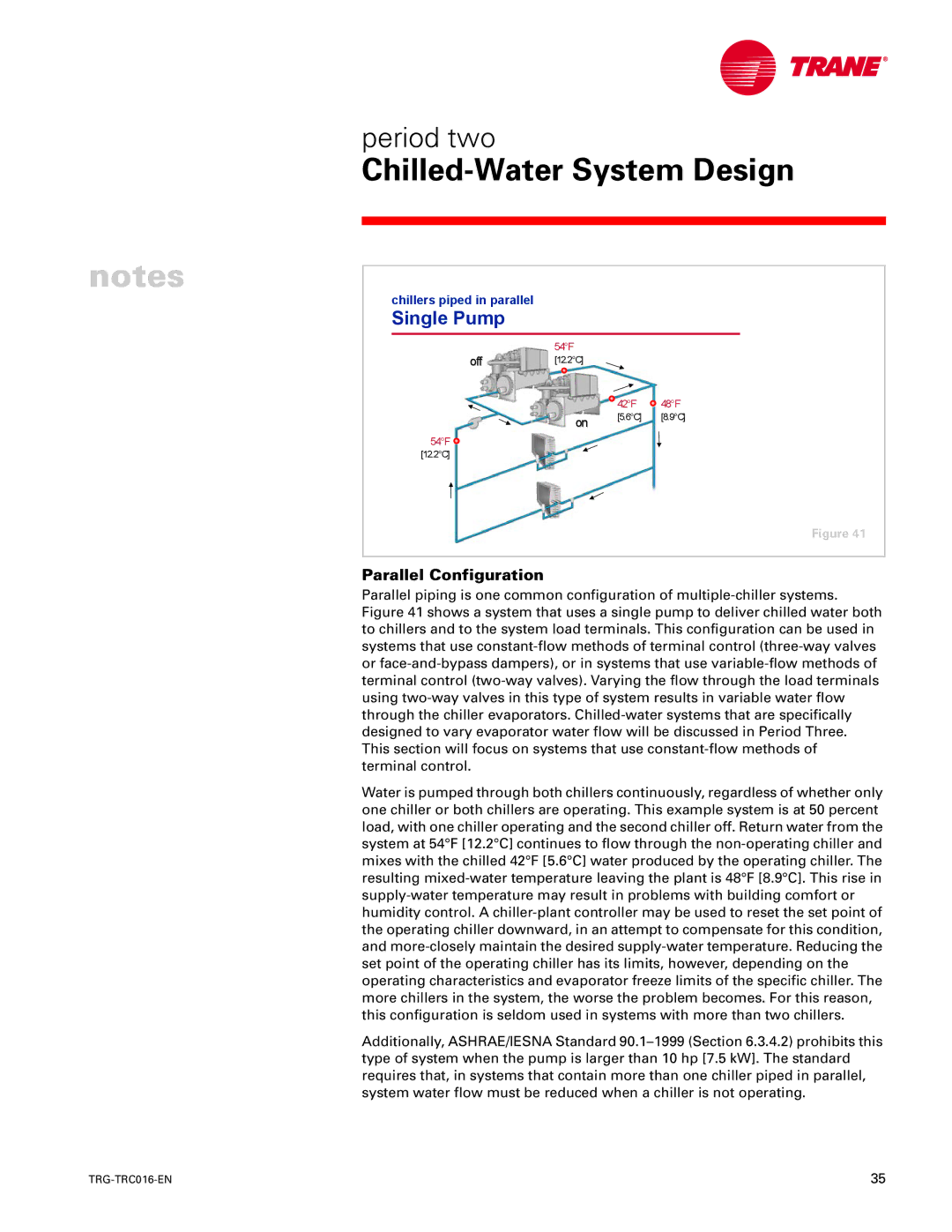

Parallel piping is one common configuration of multiple-chiller systems. Figure 41 shows a system that uses a single pump to deliver chilled water both to chillers and to the system load terminals. This configuration can be used in systems that use constant-flow methods of terminal control (three-way valves or face-and-bypass dampers), or in systems that use variable-flow methods of terminal control (two-way valves). Varying the flow through the load terminals using two-way valves in this type of system results in variable water flow through the chiller evaporators. Chilled-water systems that are specifically designed to vary evaporator water flow will be discussed in Period Three.

This section will focus on systems that use constant-flow methods of terminal control.

Water is pumped through both chillers continuously, regardless of whether only one chiller or both chillers are operating. This example system is at 50 percent load, with one chiller operating and the second chiller off. Return water from the system at 54°F [12.2°C] continues to flow through the non-operating chiller and mixes with the chilled 42°F [5.6°C] water produced by the operating chiller. The resulting mixed-water temperature leaving the plant is 48°F [8.9°C]. This rise in supply-water temperature may result in problems with building comfort or humidity control. A chiller-plant controller may be used to reset the set point of the operating chiller downward, in an attempt to compensate for this condition, and more-closely maintain the desired supply-water temperature. Reducing the set point of the operating chiller has its limits, however, depending on the operating characteristics and evaporator freeze limits of the specific chiller. The more chillers in the system, the worse the problem becomes. For this reason, this configuration is seldom used in systems with more than two chillers.

Additionally, ASHRAE/IESNA Standard 90.1–1999 (Section 6.3.4.2) prohibits this type of system when the pump is larger than 10 hp [7.5 kW]. The standard requires that, in systems that contain more than one chiller piped in parallel, system water flow must be reduced when a chiller is not operating.

![]() 42°F

42°F ![]() 48°F

48°F![]()