period three

System Variations

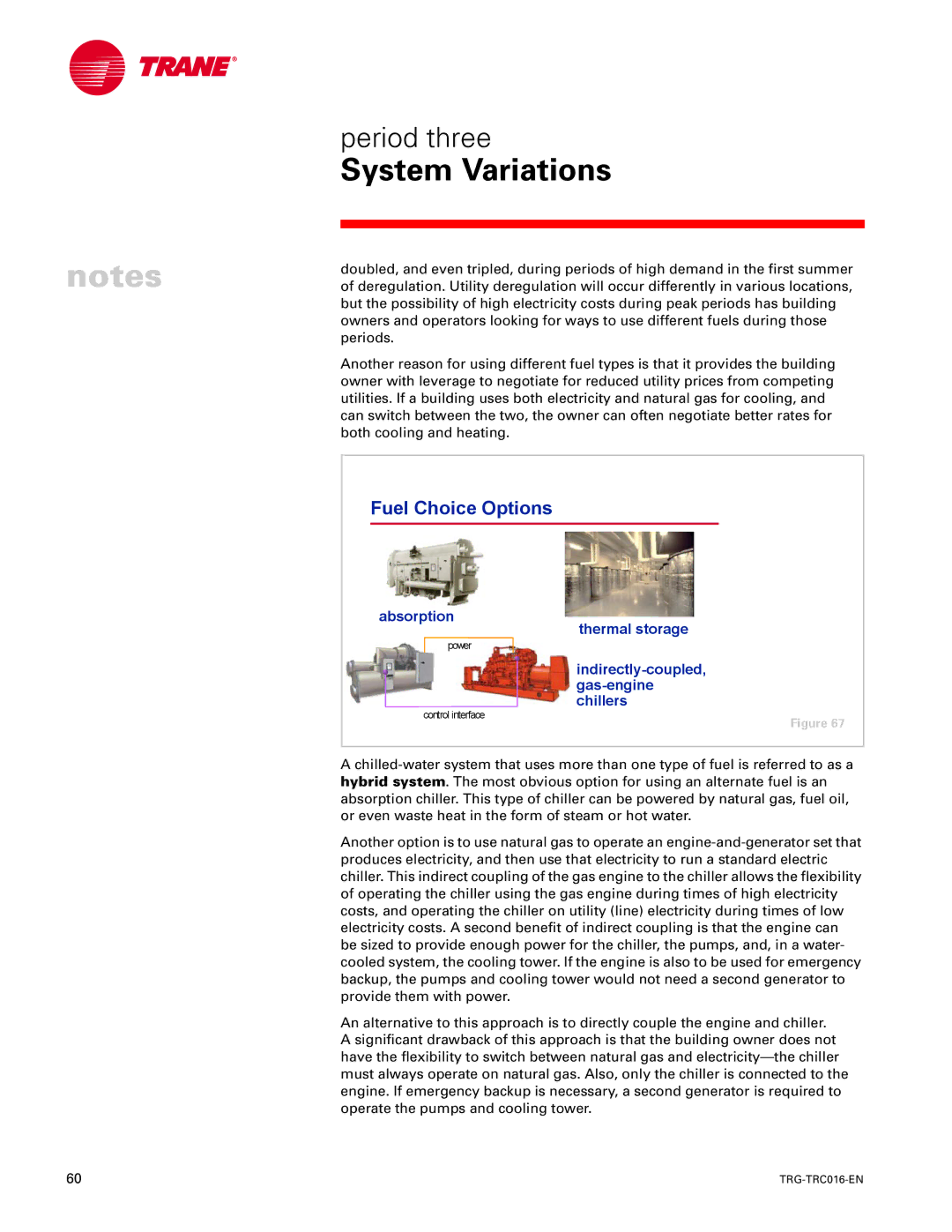

doubled, and even tripled, during periods of high demand in the first summer of deregulation. Utility deregulation will occur differently in various locations, but the possibility of high electricity costs during peak periods has building owners and operators looking for ways to use different fuels during those periods.

Another reason for using different fuel types is that it provides the building owner with leverage to negotiate for reduced utility prices from competing utilities. If a building uses both electricity and natural gas for cooling, and can switch between the two, the owner can often negotiate better rates for both cooling and heating.

Fuel Choice Options

absorption

thermal storage

power

indirectly-coupled, gas-engine chillers

control interface

Figure 67

A chilled-water system that uses more than one type of fuel is referred to as a hybrid system. The most obvious option for using an alternate fuel is an absorption chiller. This type of chiller can be powered by natural gas, fuel oil, or even waste heat in the form of steam or hot water.

Another option is to use natural gas to operate an engine-and-generator set that produces electricity, and then use that electricity to run a standard electric chiller. This indirect coupling of the gas engine to the chiller allows the flexibility of operating the chiller using the gas engine during times of high electricity costs, and operating the chiller on utility (line) electricity during times of low electricity costs. A second benefit of indirect coupling is that the engine can be sized to provide enough power for the chiller, the pumps, and, in a water- cooled system, the cooling tower. If the engine is also to be used for emergency backup, the pumps and cooling tower would not need a second generator to provide them with power.

An alternative to this approach is to directly couple the engine and chiller. A significant drawback of this approach is that the building owner does not have the flexibility to switch between natural gas and electricity—the chiller must always operate on natural gas. Also, only the chiller is connected to the engine. If emergency backup is necessary, a second generator is required to operate the pumps and cooling tower.