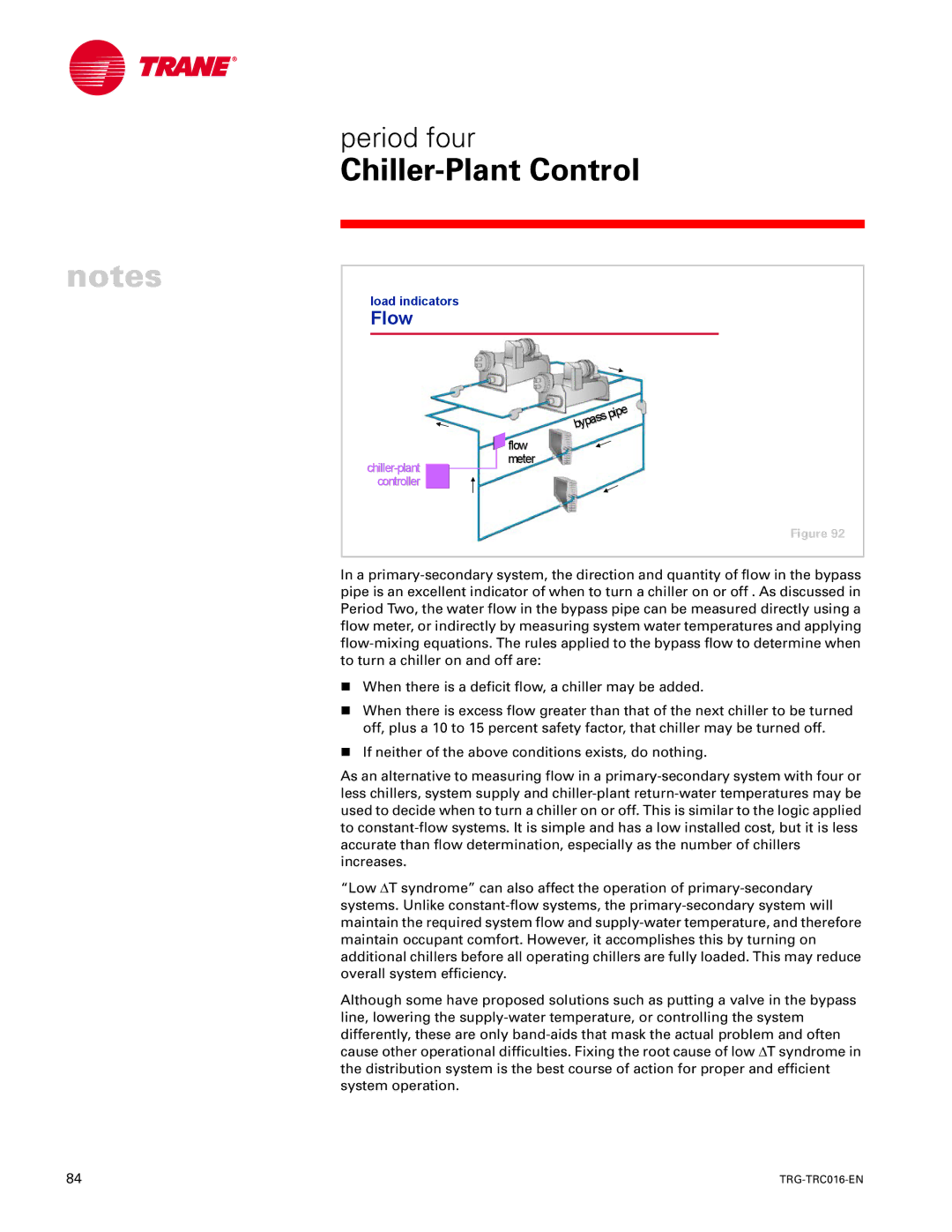

In a primary-secondary system, the direction and quantity of flow in the bypass pipe is an excellent indicator of when to turn a chiller on or off . As discussed in Period Two, the water flow in the bypass pipe can be measured directly using a flow meter, or indirectly by measuring system water temperatures and applying flow-mixing equations. The rules applied to the bypass flow to determine when to turn a chiller on and off are:

nWhen there is a deficit flow, a chiller may be added.

nWhen there is excess flow greater than that of the next chiller to be turned off, plus a 10 to 15 percent safety factor, that chiller may be turned off.

nIf neither of the above conditions exists, do nothing.

As an alternative to measuring flow in a primary-secondary system with four or less chillers, system supply and chiller-plant return-water temperatures may be used to decide when to turn a chiller on or off. This is similar to the logic applied to constant-flow systems. It is simple and has a low installed cost, but it is less accurate than flow determination, especially as the number of chillers increases.

“Low ∆T syndrome” can also affect the operation of primary-secondary systems. Unlike constant-flow systems, the primary-secondary system will maintain the required system flow and supply-water temperature, and therefore maintain occupant comfort. However, it accomplishes this by turning on additional chillers before all operating chillers are fully loaded. This may reduce overall system efficiency.

Although some have proposed solutions such as putting a valve in the bypass line, lowering the supply-water temperature, or controlling the system differently, these are only band-aids that mask the actual problem and often cause other operational difficulties. Fixing the root cause of low ∆T syndrome in the distribution system is the best course of action for proper and efficient system operation.

![]() flow meter

flow meter