period three

System Variations

notes

waterside economizer

Plate-and-Frame Heat Exchanger

plate-and-frame heat exchanger

heat exchanger

distribution  pump

pump

condenser water loop

Figure 84

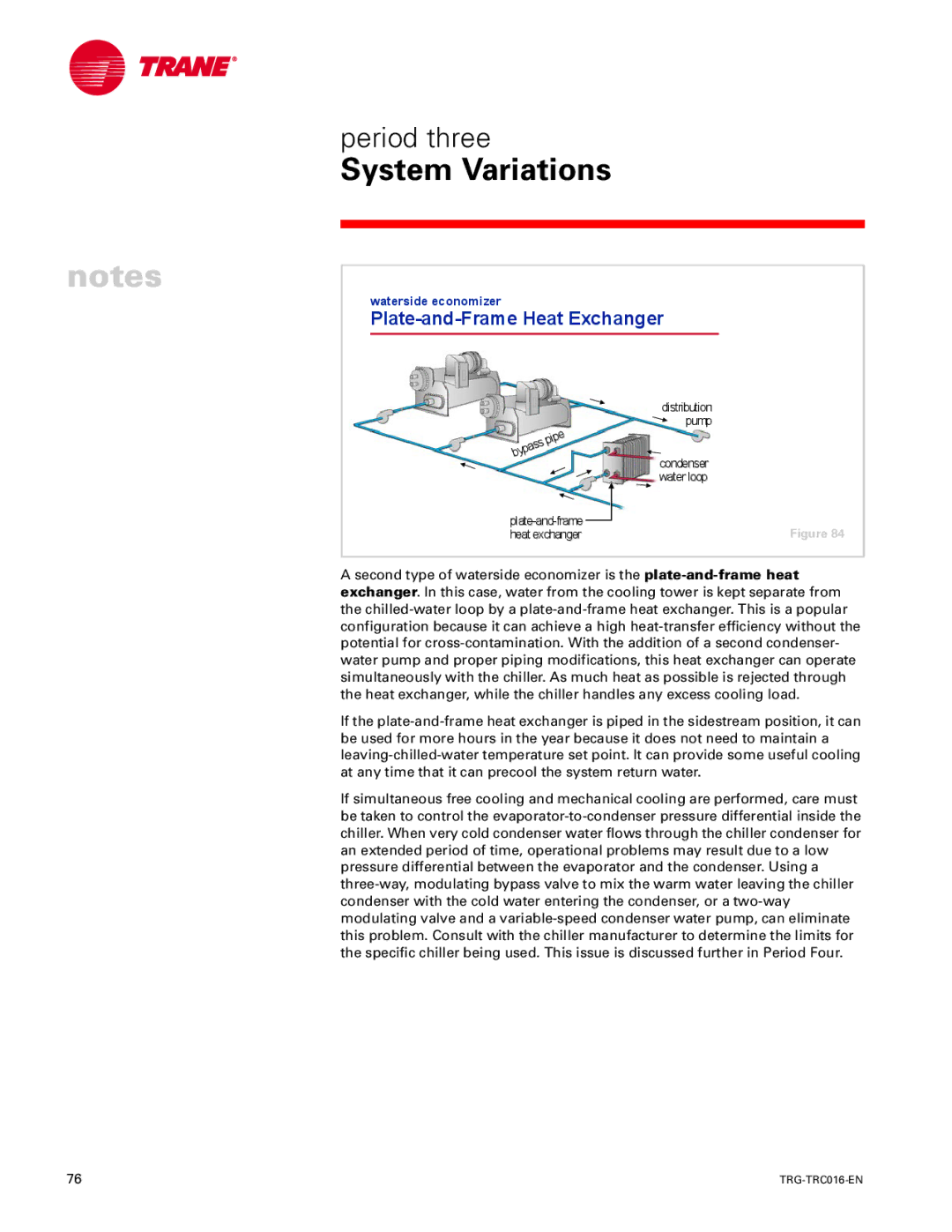

Asecond type of waterside economizer is the plate-and-frame heat exchanger. In this case, water from the cooling tower is kept separate from the chilled-water loop by a plate-and-frame heat exchanger. This is a popular configuration because it can achieve a high heat-transfer efficiency without the potential for cross-contamination. With the addition of a second condenser- water pump and proper piping modifications, this heat exchanger can operate simultaneously with the chiller. As much heat as possible is rejected through the heat exchanger, while the chiller handles any excess cooling load.

If the plate-and-frame heat exchanger is piped in the sidestream position, it can be used for more hours in the year because it does not need to maintain a leaving-chilled-water temperature set point. It can provide some useful cooling at any time that it can precool the system return water.

If simultaneous free cooling and mechanical cooling are performed, care must be taken to control the evaporator-to-condenser pressure differential inside the chiller. When very cold condenser water flows through the chiller condenser for an extended period of time, operational problems may result due to a low pressure differential between the evaporator and the condenser. Using a three-way, modulating bypass valve to mix the warm water leaving the chiller condenser with the cold water entering the condenser, or a two-way modulating valve and a variable-speed condenser water pump, can eliminate this problem. Consult with the chiller manufacturer to determine the limits for the specific chiller being used. This issue is discussed further in Period Four.

![]()

![]() pump

pump