8300 |

| 8315 L&J Tankway Software Description |

|

|

|

|

|

|

|

|

|

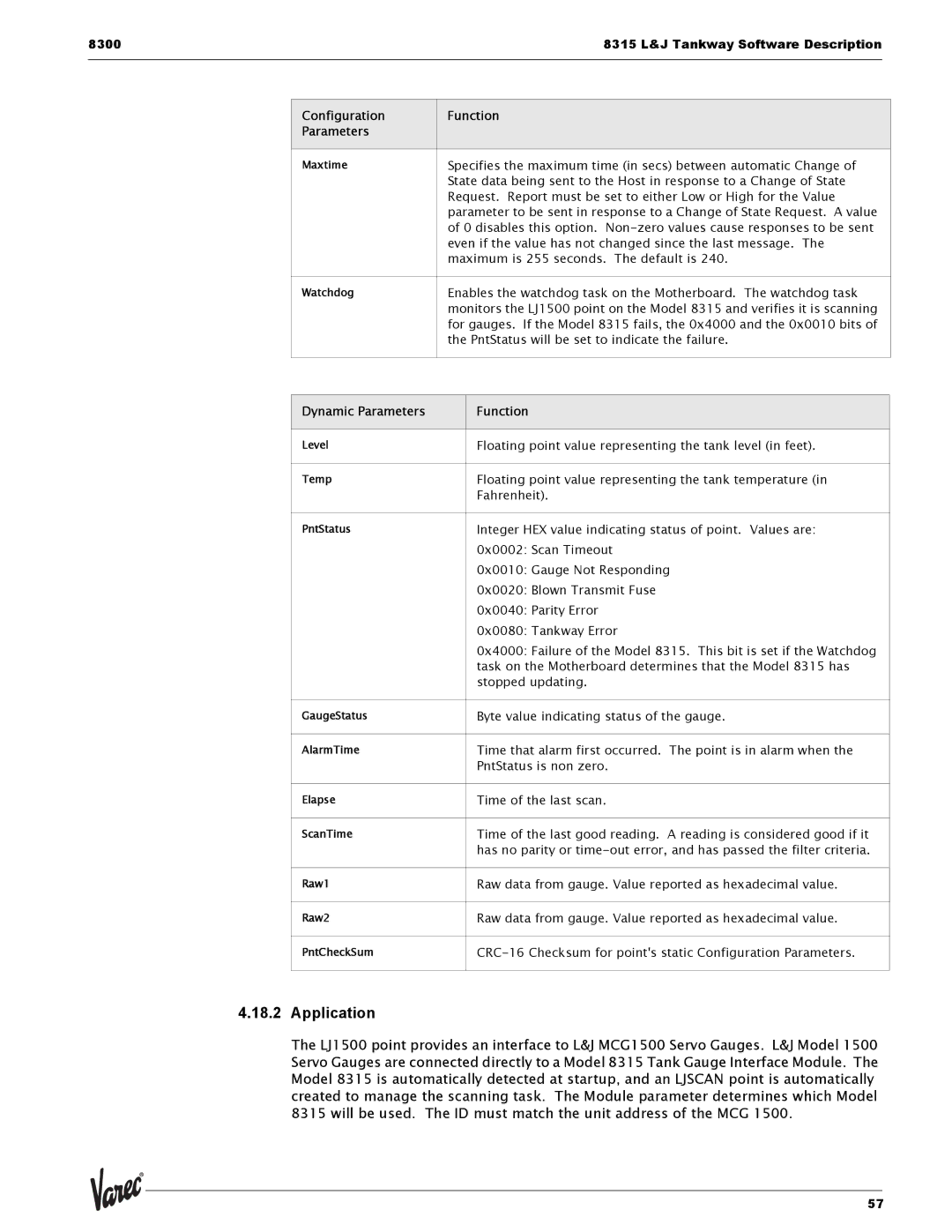

| Configuration | Function |

|

| Parameters |

|

|

|

|

|

|

| Maxtime | Specifies the maximum time (in secs) between automatic Change of |

|

|

| State data being sent to the Host in response to a Change of State |

|

|

| Request. Report must be set to either Low or High for the Value |

|

|

| parameter to be sent in response to a Change of State Request. A value |

|

|

| of 0 disables this option. |

|

|

| even if the value has not changed since the last message. The |

|

|

| maximum is 255 seconds. The default is 240. |

|

|

|

|

|

| Watchdog | Enables the watchdog task on the Motherboard. The watchdog task |

|

|

| monitors the LJ1500 point on the Model 8315 and verifies it is scanning |

|

|

| for gauges. If the Model 8315 fails, the 0x4000 and the 0x0010 bits of |

|

|

| the PntStatus will be set to indicate the failure. |

|

|

|

|

|

Dynamic Parameters | Function |

|

|

Level | Floating point value representing the tank level (in feet). |

|

|

Temp | Floating point value representing the tank temperature (in |

| Fahrenheit). |

|

|

PntStatus | Integer HEX value indicating status of point. Values are: |

| 0x0002: Scan Timeout |

| 0x0010: Gauge Not Responding |

| 0x0020: Blown Transmit Fuse |

| 0x0040: Parity Error |

| 0x0080: Tankway Error |

| 0x4000: Failure of the Model 8315. This bit is set if the Watchdog |

| task on the Motherboard determines that the Model 8315 has |

| stopped updating. |

|

|

GaugeStatus | Byte value indicating status of the gauge. |

|

|

AlarmTime | Time that alarm first occurred. The point is in alarm when the |

| PntStatus is non zero. |

|

|

Elapse | Time of the last scan. |

|

|

ScanTime | Time of the last good reading. A reading is considered good if it |

| has no parity or |

|

|

Raw1 | Raw data from gauge. Value reported as hexadecimal value. |

|

|

Raw2 | Raw data from gauge. Value reported as hexadecimal value. |

|

|

PntCheckSum | |

|

|

4.18.2Application

The LJ1500 point provides an interface to L&J MCG1500 Servo Gauges. L&J Model 1500 Servo Gauges are connected directly to a Model 8315 Tank Gauge Interface Module. The Model 8315 is automatically detected at startup, and an LJSCAN point is automatically created to manage the scanning task. The Module parameter determines which Model 8315 will be used. The ID must match the unit address of the MCG 1500.

57