R3 |

|

| End | Locking |

|

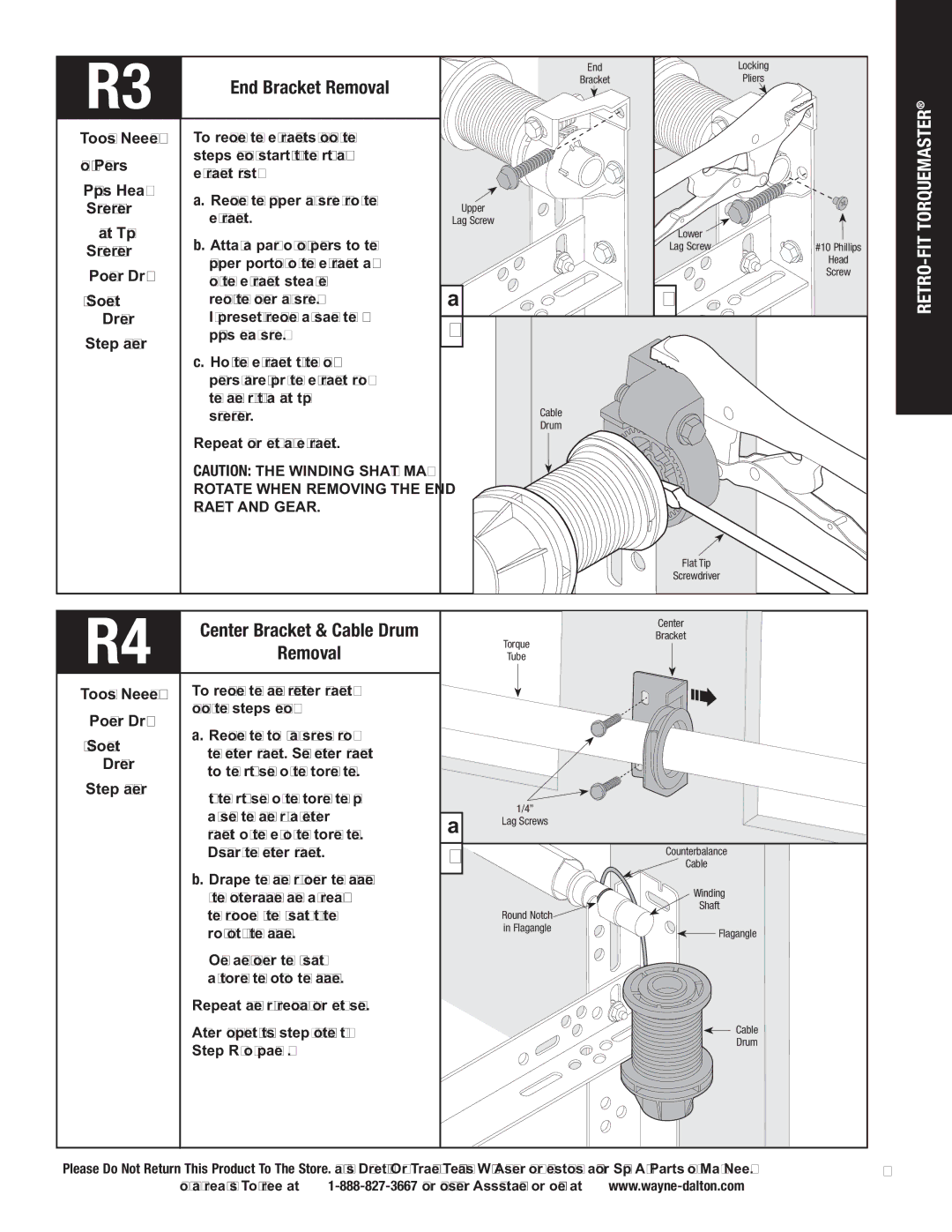

End Bracket Removal |

| Bracket | Pliers |

| |

|

|

| |||

|

|

|

|

| |

Tools Needed: | To remove the end brackets, follow the |

|

|

|

|

Locking Pliers | steps below starting with the right hand |

|

|

|

|

end bracket first: |

|

|

|

| |

|

|

|

|

| |

Phillips Head | a. Remove the upper lag screw from the |

|

|

|

|

Screwdriver | Upper |

|

|

| |

end bracket. |

|

|

| ||

Flat Tip | Lag Screw |

|

|

| |

b. Attach a pair of locking pliers to the |

|

| Lower |

| |

Screwdriver |

|

| Lag Screw | #10 Phillips | |

upper portion of the end bracket and |

|

|

| Head | |

|

|

|

| ||

Power Drill | hold the end bracket steady while |

|

|

| Screw |

|

|

|

| ||

| a |

| b |

| |

7/16” Socket | removing the lower lag screw. |

|

| ||

Driver | If present, remove and save the #10 | c |

|

|

|

Step Ladder | phillips head screw. |

|

|

| |

|

|

|

|

| |

| c. Holding the end bracket with the locking |

|

|

|

|

| pliers, carefully pry the end bracket from |

|

|

|

|

| the cable drum with a flat tip |

|

|

|

|

| screwdriver. |

| Cable |

|

|

|

|

| Drum |

|

|

| Repeat for left hand end bracket. |

|

|

|

|

| CAUTION: THE WINDING SHAFT MAY |

|

|

|

|

| ROTATE WHEN REMOVING THE END |

|

|

|

|

| BRACKET AND GEAR. |

|

|

|

|

|

|

|

| Flat Tip |

|

R4 |

|

|

| Screwdriver |

|

Center Bracket & Cable Drum |

|

| Center |

| |

|

|

|

| ||

|

| Torque | Bracket |

| |

| Removal |

|

|

| |

|

| Tube |

|

| |

Tools Needed: | To remove the cable drum/center bracket, |

|

|

|

|

Power Drill | follow the steps below: |

|

|

|

|

a. Remove the two 1/4" lag screws from |

|

|

|

| |

7/16" Socket |

|

|

|

| |

the center bracket. Slide center bracket |

|

|

|

| |

Driver |

|

|

|

| |

to the right side of the torque tube. |

|

|

|

| |

|

|

|

|

| |

Step Ladder | Lift the right side of the torque tube up |

|

|

|

|

|

| 1/4” |

|

| |

| and slide the cable drum and center | a |

|

| |

| Lag Screws |

|

| ||

| bracket off the end of the torque tube. |

|

|

| |

|

|

|

|

| |

| Discard the center bracket. | b |

| Counterbalance |

|

|

|

| Cable |

| |

| b. Drape the cable drum over the flagangle |

|

| Winding |

|

| by the counterbalance cable and |

|

|

| |

|

|

| Shaft |

| |

| the groove in the winding shaft with the |

| Round Notch |

| |

|

|

|

| ||

| round notch in the flagangle. |

| in Flagangle | Flagangle |

|

|

|

|

| ||

| Once aligned, lower the winding shaft |

|

|

|

|

| and torque tube onto the flagangle. |

|

|

|

|

| Repeat cable drum removal for left side. |

|

|

|

|

| After completing this step, continue with |

|

| Cable |

|

| Step R5 on page 5. |

|

| Drum |

|

|

|

|

|

|

RETRO-FIT TORQUEMASTER®

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need. 4 You can reach us Toll Free at