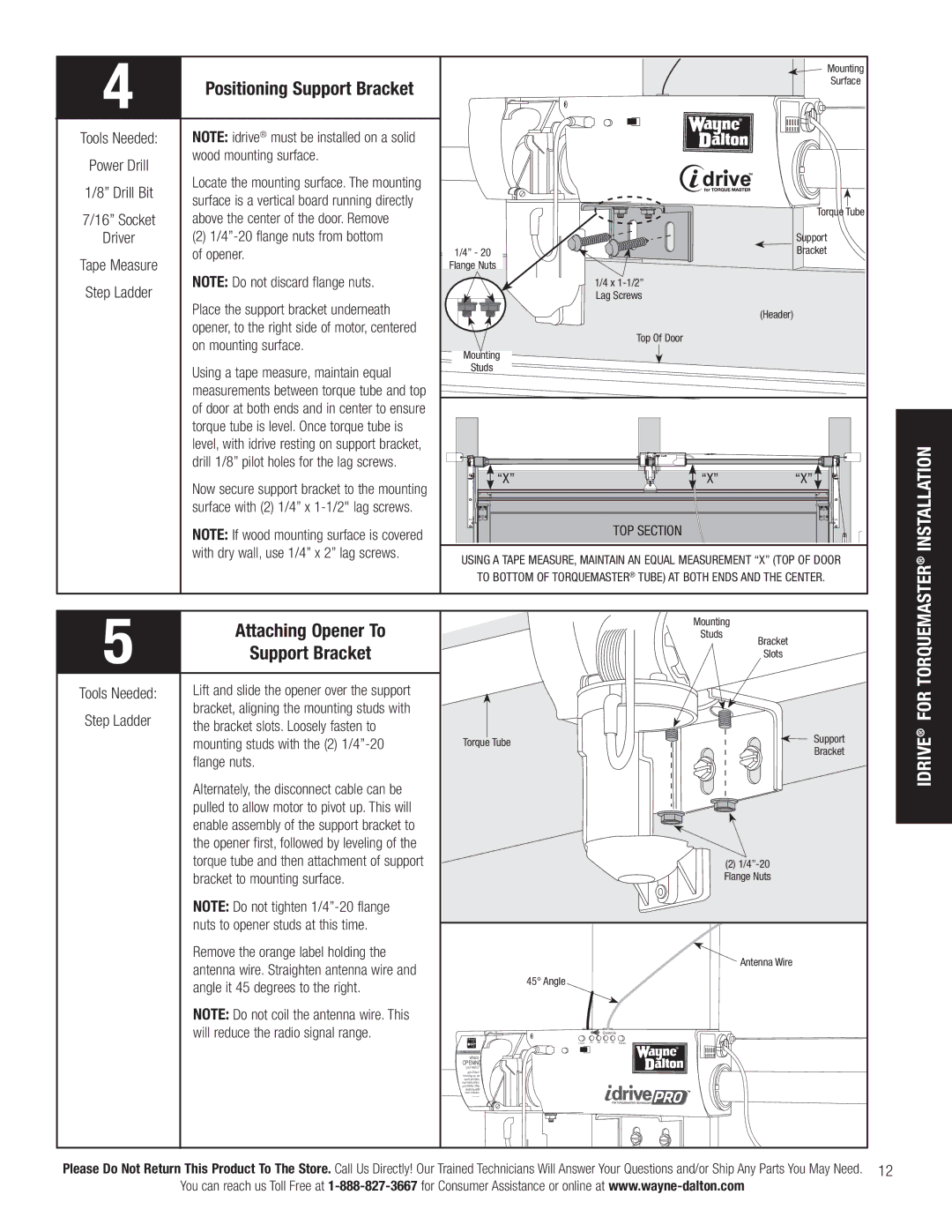

4Positioning Support Bracket

Tools Needed: | NOTE: idrive® must be installed on a solid | |

Power Drill | wood mounting surface. | |

| ||

1/8” Drill Bit | Locate the mounting surface. The mounting | |

surface is a vertical board running directly | ||

| ||

7/16” Socket | above the center of the door. Remove | |

Driver | (2) | |

Tape Measure | of opener. | |

NOTE: Do not discard flange nuts. | ||

Step Ladder | ||

| ||

| Place the support bracket underneath | |

| opener, to the right side of motor, centered | |

| on mounting surface. | |

| Using a tape measure, maintain equal | |

| measurements between torque tube and top | |

| of door at both ends and in center to ensure | |

| torque tube is level. Once torque tube is | |

| level, with idrive resting on support bracket, | |

| drill 1/8” pilot holes for the lag screws. | |

| Now secure support bracket to the mounting | |

| surface with (2) 1/4” x | |

| NOTE: If wood mounting surface is covered | |

| with dry wall, use 1/4” x 2” lag screws. |

|

| Mounting |

|

| Surface |

|

| Torque Tube |

|

| Support |

1/4” - 20 |

| Bracket |

Flange Nuts |

|

|

| 1/4 x |

|

| Lag Screws |

|

|

| (Header) |

| Top Of Door |

|

Mounting |

|

|

Studs |

|

|

“X” | “X” | “X” |

| TOP SECTION |

|

USING A TAPE MEASURE, MAINTAIN AN EQUAL MEASUREMENT “X” (TOP OF DOOR | ||

TO BOTTOM OF TORQUEMASTER® TUBE) AT BOTH ENDS AND THE CENTER. | ||

® INSTALLATION

5 | Attaching Opener To |

|

|

|

| Mounting | |

|

|

|

|

| |||

|

|

|

|

| Studs | Bracket | |

| Support Bracket |

|

|

|

|

| |

|

|

|

|

|

| Slots | |

Tools Needed: | Lift and slide the opener over the support |

|

|

|

|

|

|

Step Ladder | bracket, aligning the mounting studs with |

|

|

|

|

|

|

the bracket slots. Loosely fasten to |

|

|

|

|

|

| |

|

|

|

|

|

| Support | |

| mounting studs with the (2) | Torque Tube |

|

|

|

| |

|

|

|

|

| Bracket | ||

| flange nuts. |

|

|

|

|

| |

|

|

|

|

|

|

| |

| Alternately, the disconnect cable can be |

|

|

|

|

|

|

| pulled to allow motor to pivot up. This will |

|

|

|

|

|

|

| enable assembly of the support bracket to |

|

|

|

|

|

|

| the opener first, followed by leveling of the |

|

|

|

|

|

|

| torque tube and then attachment of support |

|

|

|

|

| (2) |

| bracket to mounting surface. |

|

|

|

|

| Flange Nuts |

| NOTE: Do not tighten |

|

|

|

|

|

|

| nuts to opener studs at this time. |

|

|

|

|

|

|

| Remove the orange label holding the |

|

|

|

|

| Antenna Wire |

| antenna wire. Straighten antenna wire and |

|

|

|

|

| |

| 45° Angle |

|

|

|

|

| |

| angle it 45 degrees to the right. |

|

|

|

|

| |

|

|

|

|

|

|

| |

| NOTE: Do not coil the antenna wire. This |

|

|

|

|

|

|

| will reduce the radio signal range. |

|

|

| Controls |

|

|

|

| Learn | S1 | S2 | S3 S4 | Delete |

|

|

|

|

|

|

|

| |

|

| what’s |

|

|

|

|

|

|

| OPENING |

|

|

|

|

|

|

| your world? |

|

|

|

|

|

|

| ® |

|

|

|

|

|

|

| With |

|

|

|

|

|

|

| technology you can |

|

|

|

|

|

|

| control yourlights, |

|

|

|

|

|

|

| thermostat andstart |

|

|

|

|

|

|

| your morning coffee, |

|

|

|

|

|

|

| all withthe single |

|

|

|

|

|

|

| touchof a button. |

|

|

|

|

|

|

| Find out more: |

|

|

|

|

|

|

|

|

|

|

|

| |

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need. 12 You can reach us Toll Free at

IDRIVE® FOR TORQUEMASTER