Routine Care and Adjustment

Media Sensor Position Adjustment

This procedure was covered in Chapter 1. See page 10.

Ribbon Supply Spindle Adjustment

This procedure was covered in Chapter 1. See page 11.

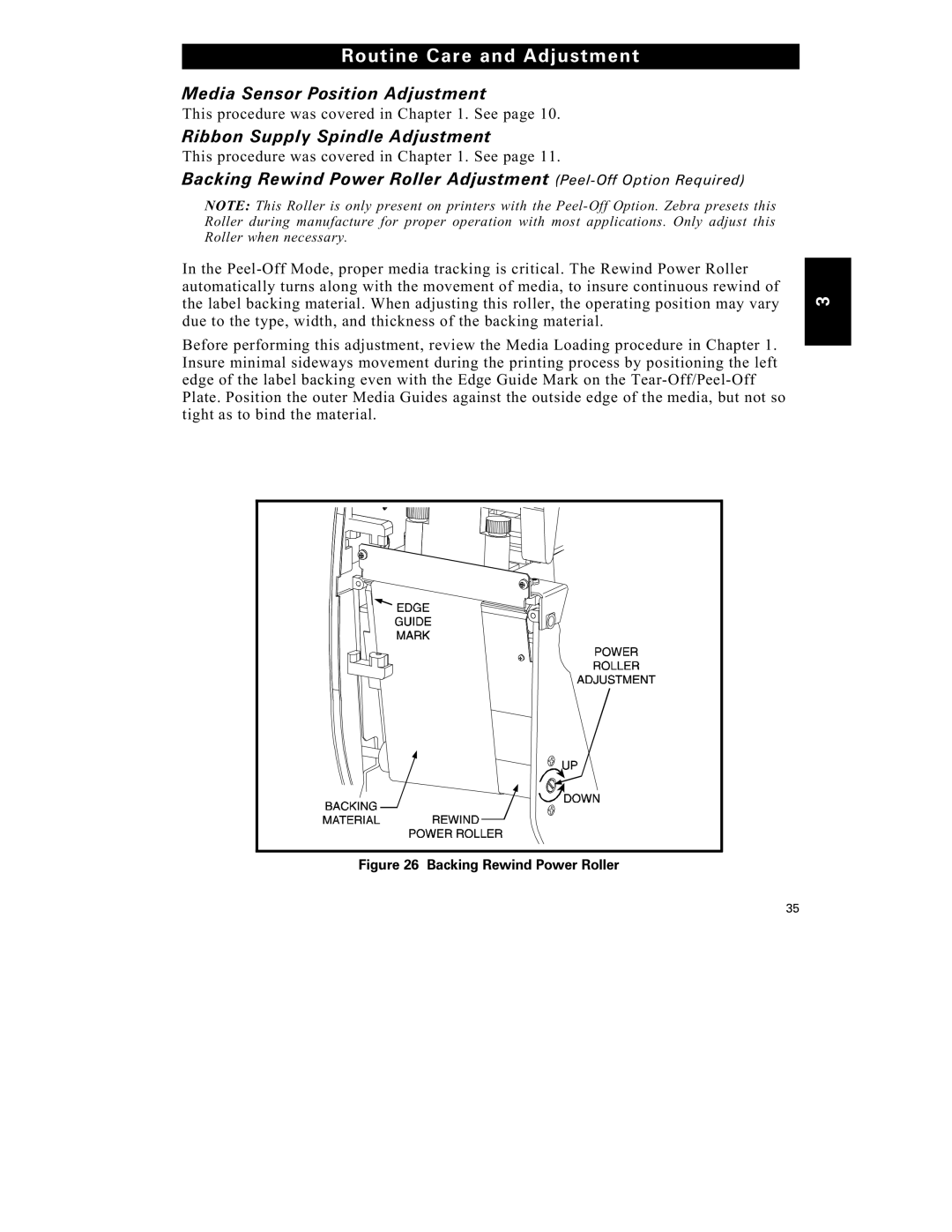

Backing Rewind Power Roller Adjustment (Peel-Off Option Required)

NOTE: This Roller is only present on printers with the Peel-Off Option. Zebra presets this Roller during manufacture for proper operation with most applications. Only adjust this Roller when necessary.

In the Peel-Off Mode, proper media tracking is critical. The Rewind Power Roller automatically turns along with the movement of media, to insure continuous rewind of the label backing material. When adjusting this roller, the operating position may vary due to the type, width, and thickness of the backing material.

Before performing this adjustment, review the Media Loading procedure in Chapter 1. Insure minimal sideways movement during the printing process by positioning the left edge of the label backing even with the Edge Guide Mark on the Tear-Off/Peel-Off Plate. Position the outer Media Guides against the outside edge of the media, but not so tight as to bind the material.

Figure 26 Backing Rewind Power Roller