V. Removal and Replacement of Components

![]() WARNING

WARNING

1.This unit should be diagnosed and repaired only by qualified service personnel to reduce the risk of death, electric shock, serious injury, or fire.

2.Move the control switch to the "OFF" position and turn off the power supply before servicing.

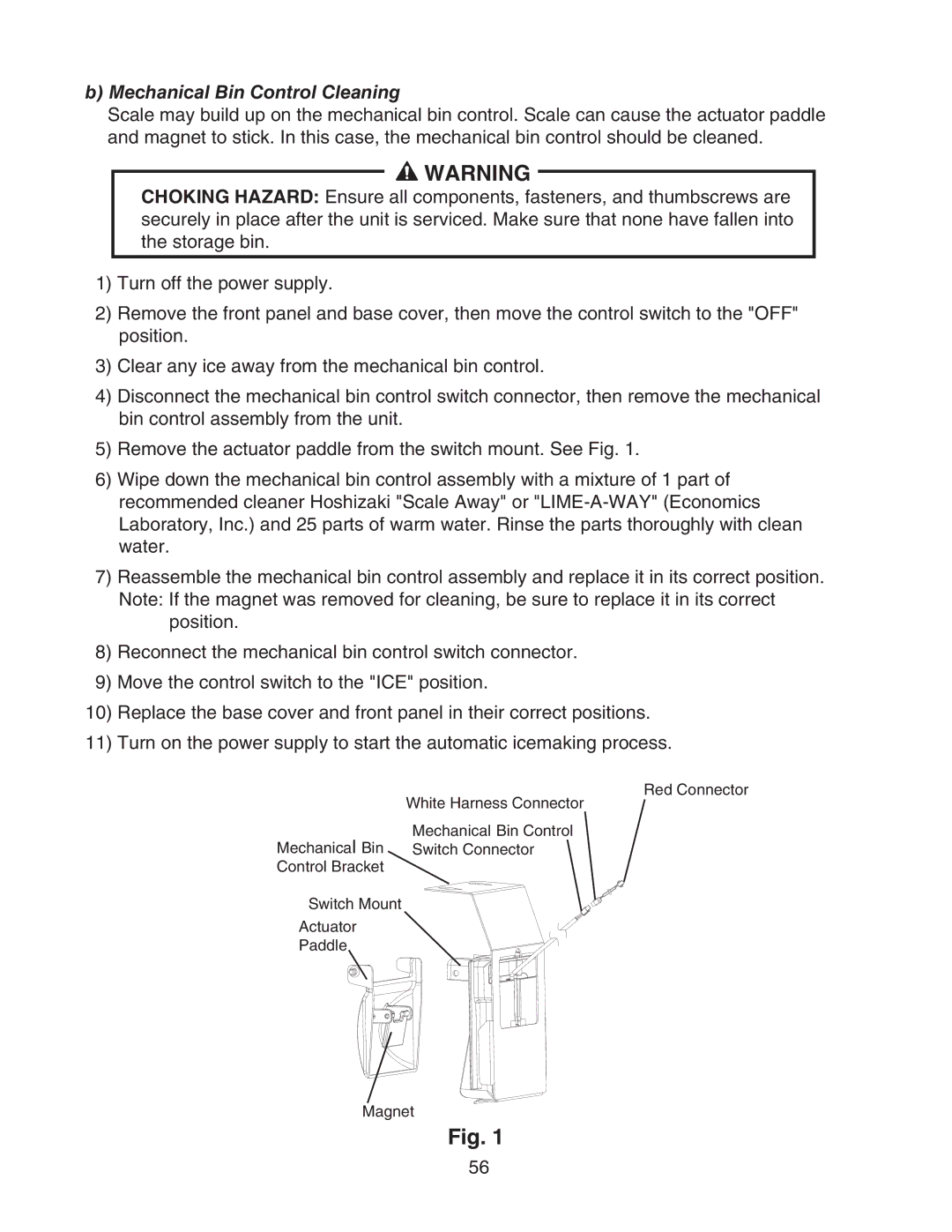

3.CHOKING HAZARD: Ensure all components, fasteners, and thumbscrews are securely in place after the unit is serviced. Make sure that none have fallen into the storage bin.

4.Make sure all food zones in the icemaker and storage bin are clean after the unit is serviced. For cleaning procedures, see "VI. Cleaning and Maintenance."

A.Service for Refrigerant Lines

![]() WARNING

WARNING

1.Repairs requiring the refrigeration circuit to be opened must be performed by properly trained and

2.Always recover the refrigerant and store it in an approved container. Do not discharge the refrigerant into the atmosphere.

3.Use an electronic leak detector or soap bubbles to check for leaks. Add a trace of refrigerant to the system (if using an electronic leak detector), and then raise the pressure using nitrogen gas (140 PSIG). DO NOT use

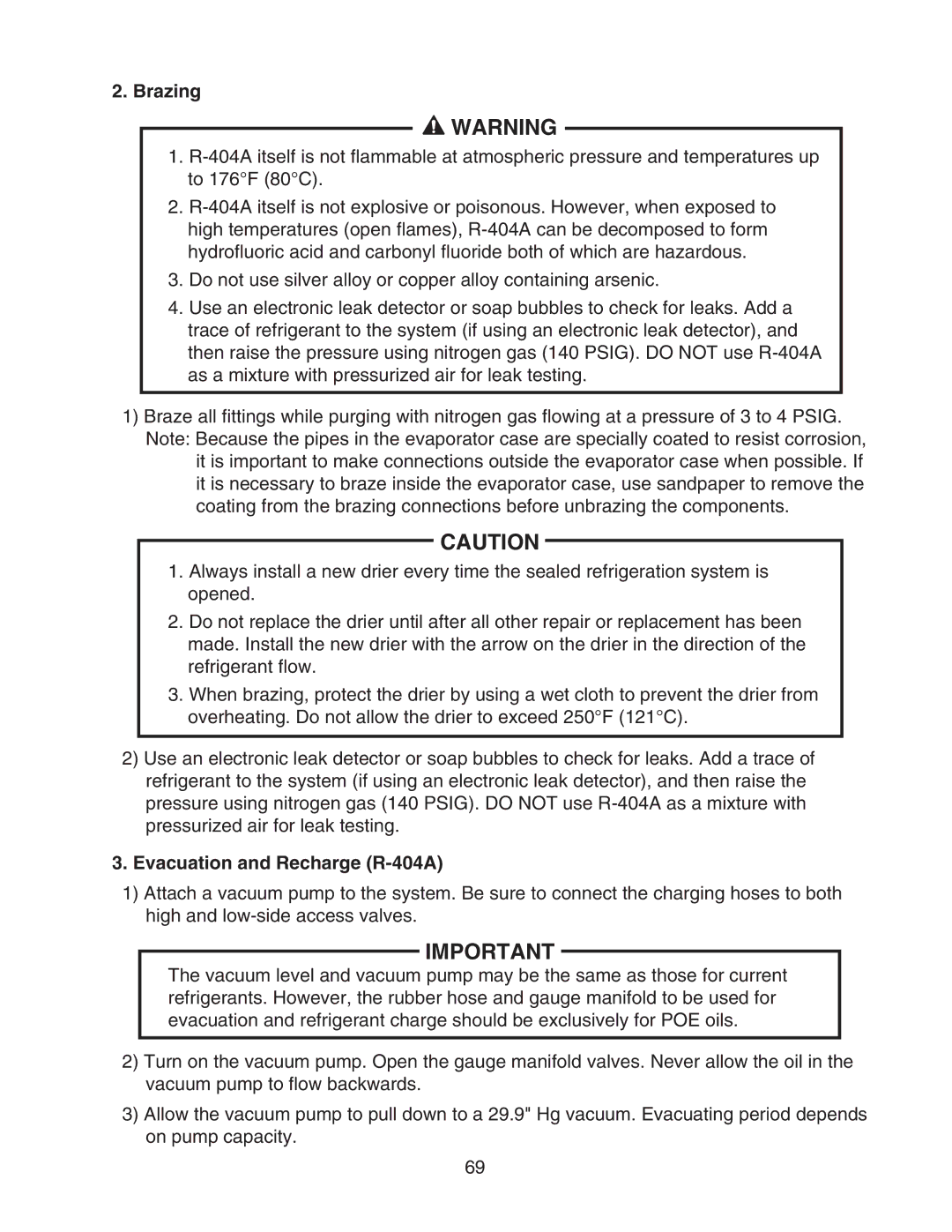

CAUTION

1.Do not leave the system open for longer than 15 minutes when replacing or servicing parts. The Polyol Ester (POE) oils used in

2.Always install a new drier every time the sealed refrigeration system is opened.

3.Do not replace the drier until after all other repair or replacement has been made. Install the new drier with the arrow on the drier in the direction of the refrigerant flow.

4.When brazing, protect the drier by using a wet cloth to prevent the drier from overheating. Do not allow the drier to exceed 250°F (121°C).

1.Refrigerant Recovery

The icemaker unit is provided with refrigerant access valves. Using proper refrigerant practices, recover the refrigerant from the access valves and store it in an approved container. Do not discharge the refrigerant into the atmosphere.

68