![]() BM 2610012089

BM 2610012089

Adjustments

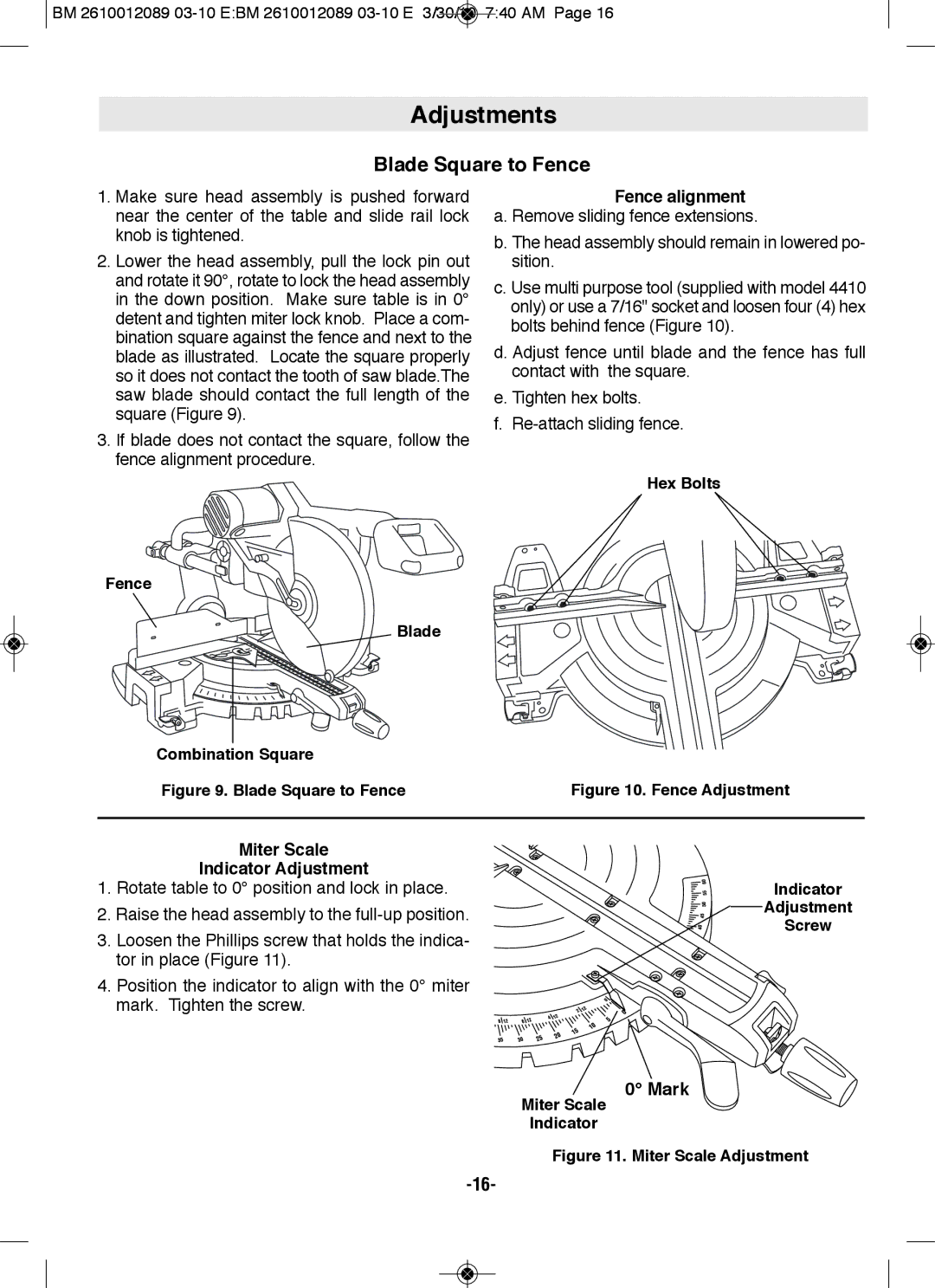

Blade Square to fence

1.Make sure head assembly is pushed forward near the center of the table and slide rail lock knob is tightened.

2.Lower the head assembly, pull the lock pin out and rotate it 90°, rotate to lock the head assembly in the down position. Make sure table is in 0° detent and tighten miter lock knob. Place a com- bination square against the fence and next to the blade as illustrated. Locate the square properly so it does not contact the tooth of saw blade.The saw blade should contact the full length of the square (Figure 9).

3.If blade does not contact the square, follow the fence alignment procedure.

fence

Blade

Combination Square

figure 9. Blade Square to fence

fence alignment

a. Remove sliding fence extensions.

b. The head assembly should remain in lowered po- sition.

c. Use multi purpose tool (supplied with model 4410 only) or use a 7/16" socket and loosen four (4) hex bolts behind fence (Figure 10).

d. Adjust fence until blade and the fence has full contact with the square.

e. Tighten hex bolts.

f.

Hex Bolts

figure 10. fence Adjustment

Miter Scale

Indicator Adjustment

1. Rotate table to 0° position and lock in place.

2. Raise the head assembly to the

3.Loosen the Phillips screw that holds the indica- tor in place (Figure 11).

4. Position the indicator to align with the 0° miter mark. Tighten the screw.

0° Mark

Miter Scale

Indicator

Indicator