BM 2610012089

BM 2610012089 03-10 E:BM 2610012089 03-10 E 3/30/10 7:42 AM Page 31

Saw Operations

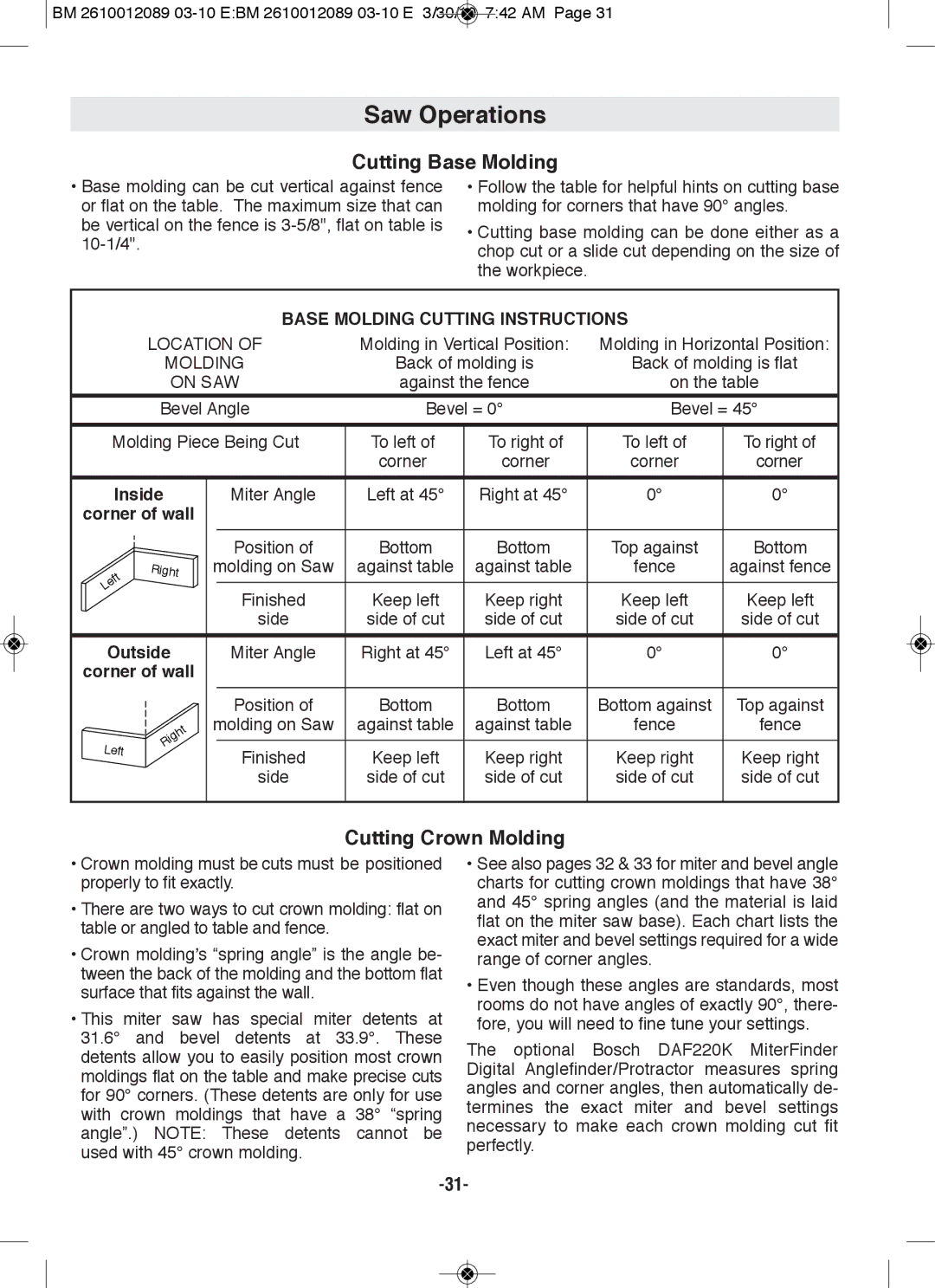

Cutting Base Molding

•Base molding can be cut vertical against fence or flat on the table. The maximum size that can be vertical on the fence is

•Follow the table for helpful hints on cutting base molding for corners that have 90° angles.

•Cutting base molding can be done either as a chop cut or a slide cut depending on the size of the workpiece.

| BASE MOlDING CUTTING INSTRUCTIONS |

| |||

LOCATION OF | Molding in Vertical Position: | Molding in Horizontal Position: | |||

| MOLDING | Back of molding is | Back of molding is flat | ||

| ON SAW | against the fence | on the table | ||

Bevel Angle | Bevel = 0° | Bevel = 45° | |||

|

|

|

|

| |

Molding Piece Being Cut | To left of | To right of | To left of | To right of | |

|

| corner | corner | corner | corner |

|

|

|

|

|

|

Inside | Miter Angle | Left at 45° | Right at 45° | 0° | 0° |

corner of wall

Right

Outside

corner of wall

Left | Right |

|

| Position of | Bottom | Bottom | Top against | Bottom |

molding on Saw | against table | against table | fence | against fence | |

|

|

|

|

|

|

| Finished | Keep left | Keep right | Keep left | Keep left |

| side | side of cut | side of cut | side of cut | side of cut |

| Miter Angle | Right at 45° | Left at 45° | 0° | 0° |

|

|

|

|

|

|

| Position of | Bottom | Bottom | Bottom against | Top against |

molding on Saw | against table | against table | fence | fence | |

|

|

|

|

|

|

| Finished | Keep left | Keep right | Keep right | Keep right |

| side | side of cut | side of cut | side of cut | side of cut |

Cutting Crown Molding

•Crown molding must be cuts must be positioned properly to fit exactly.

•There are two ways to cut crown molding: flat on table or angled to table and fence.

•Crown molding’s “spring angle” is the angle be- tween the back of the molding and the bottom flat surface that fits against the wall.

•This miter saw has special miter detents at 31.6° and bevel detents at 33.9°. These detents allow you to easily position most crown moldings flat on the table and make precise cuts for 90° corners. (These detents are only for use with crown moldings that have a 38° “spring angle”.) NOTE: These detents cannot be used with 45° crown molding.

•See also pages 32 & 33 for miter and bevel angle charts for cutting crown moldings that have 38° and 45° spring angles (and the material is laid flat on the miter saw base). Each chart lists the exact miter and bevel settings required for a wide range of corner angles.

•Even though these angles are standards, most rooms do not have angles of exactly 90°, there- fore, you will need to fine tune your settings.

The optional Bosch DAF220K MiterFinder Digital Anglefinder/Protractor measures spring angles and corner angles, then automatically de- termines the exact miter and bevel settings necessary to make each crown molding cut fit perfectly.