IMPORTANT: There is no way to reset/restore the factory default configurations; use caution when making changes to any set point or operational variable.

The EconoMi$er+ control accepts an occupied/unoccupied switch input. This input is used to control the occupied and unoccupied minimum ventilation damper position as shown in Table 37 items 2 (ECONOMIN_SP) and 3 (U_ECONOMIN_SP). These values represent the minimum damper position. In addition, the controls allows for different modes of compressor operation in the unoccupied mode. Using item 13 in Table 37 (OCC_MODE), the user can select one of the following unoccupied modes:

•No unoccupied cooling

•Unoccupied free cooling (EconoMi$er+)

•Unoccupied free cooling and mechanical cooling

The EconoMi$er+ will control the cooling operation of the unit based on the demand from the thermostat outputs Y1 and Y2. The EconoMi$er+ will monitor the fan output G, but will not control the fan directly. Note that G must be ener- gized for any cooling to take place. Gas or electric heating will be controlled directly from the thermostat.

When a demand for cooling occurs, the control will check to see if it is in the occupied or unoccupied mode. Depending on the configuration, the control will move the outside air damper to the ventilation position. If the outside air condi- tions are acceptable, then the control will use the EconoMi$er+ for free cooling. If the supply air temperature does not meet the configurable set point, then the control will turn on additional stages of mechanical cooling. Several compressor sequences can be used depending on the applica- tion requirements; these will be covered in the mechanical compressor staging section.

A. Compressor Configuration and Control

The EconoMi$er+ control can support from 1 to 4 compressor stages. For the 3 to 12 1/2 ton units, there will only be 1 or 2 stages of compressor cooling, so the control is factory configured for 2 stages. There is no difference between 1 and 2 stages. The control also provides the option to configure for high sensible or high latent loads, but for units with only two compressors this option does not apply.

Compressors are configured using item 10 (STAGE_TYPE) in Table 37. The control also has the capability of controlling directly to Y1 and Y2 inputs. The control can be configured to control to the leaving air temperature using Y1 and Y2 as a low cool and high cool demand based on the supply air set point and the rate of change of supply air temperature. For low cool the leaving air temperature set point will be SAT_SP+2° F. For high cool the leaving air temperature set point will be the supply air temperature set point (SAT_SP).

To use this option, configure the compressor sequencing vari- able (STAGE_TYPE) to a value of 3. Configure the supply air temperature set point (SAT_SP) to the desired leaving-air temperature.

NOTE: The supply air temperature set point is also the tem- perature used for EconoMi$er+ control.

The logic will control the operation of the compressors depending on the configuration selected. If free cooling can be used, then the compressors will be integrated with the EconoMi$er+ to provide the lowest cost cooling control. The logic includes time guards on the compressors to provide a minimum of 3 minutes on and 3 minutes off time. The con- trol will also prevent two compressors from starting at the same time. The logic uses the EconoMi$er+ to prevent rapid cycling of the compressors and low air temperatures.

B. Ventilation Air and Free Cooling

In order for the EconoMi$er+ to control ventilation air and free cooling, several items must be configured.

EconoMi$er+ Type

First, select the EconoMi$er+ control type that will be used. This is the EconoMi$er+ Type function (ECONO_TYPE) defined by item 5 in Table 37. The choices are:

1.Vent only — This is used to have just ventilation con- trol. The EconoMi$er+ will not provide free cooling, but the occupied and unoccupied minimum positions can be used.

2.Proportional — In this configuration, full proportion- al EconoMi$er+ control will be used. When EconoMi$er+ free cooling cannot be used, the damp- ers will be set to the appropriate occupied and unoc- cupied minimum positions.

3.Three-Position — This mode of EconoMi$er+ is used to provide a minimum ventilation EconoMi$er+ posi- tion and a fixed free cooling or high ventilation posi- tion. The high ventilation position is controlled by the optional Remote EconoMi$er+ Enable Switch Input connected to terminals 11 and 12 on T3.

Supply Air Temperature Set Point

Once the type of EconoMi$er+ control has been selected, the user will need to set the Supply Air Temperature set point (SAT_SP). The SAT_SP has a range of 40 to 65 F.

NOTE: This will be the set point when both Y1 and Y2 are closed. When just Y1 is closed, the set point will be 2 F higher.

Minimum Damper Position

Set the occupied minimum damper position (ECONOMIN_SP) and unoccupied minimum position (U_ECONOMIN_SP). These should be set to provide the ventilation requirements at full occupancy as defined by the building specifications. When demand ventilation is used, the control will close the dampers below this position based on measured CO2 levels in the space to provide additional operation savings.

The control will also allow for the use of a remote minimum position potentiometer. This will only adjust the Occupied Minimum position. If used, the software set point ECONOMIN_SP should be set to 0 as the control will use the largest set point.

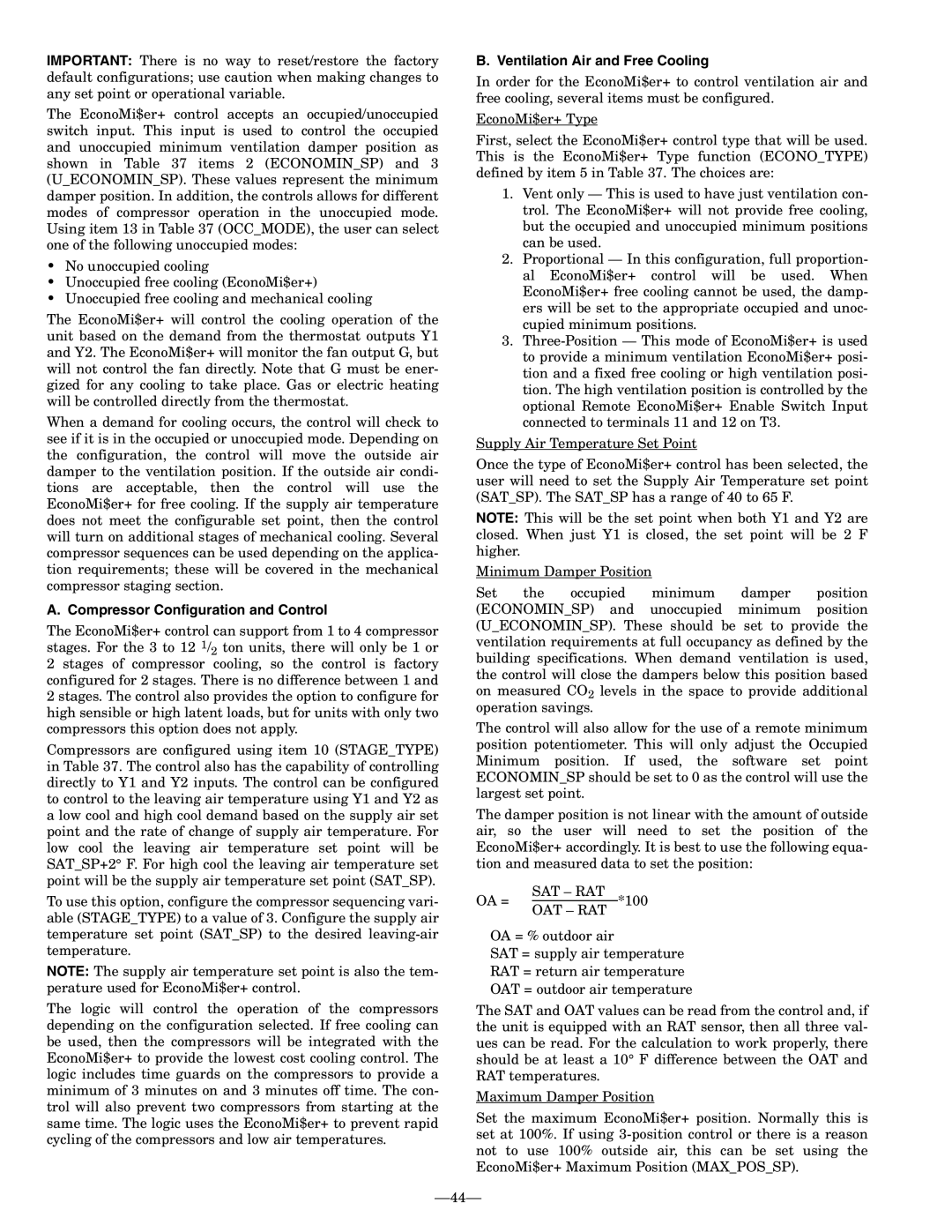

The damper position is not linear with the amount of outside air, so the user will need to set the position of the EconoMi$er+ accordingly. It is best to use the following equa- tion and measured data to set the position:

| OA = | SAT – RAT | *100 |

| OAT – RAT |

| | |

OA = % outdoor air

SAT = supply air temperature

RAT = return air temperature

OAT = outdoor air temperature

The SAT and OAT values can be read from the control and, if the unit is equipped with an RAT sensor, then all three val- ues can be read. For the calculation to work properly, there should be at least a 10° F difference between the OAT and RAT temperatures.

Maximum Damper Position

Set the maximum EconoMi$er+ position. Normally this is set at 100%. If using 3-position control or there is a reason not to use 100% outside air, this can be set using the EconoMi$er+ Maximum Position (MAX_POS_SP).