38AU

Liquid Line Filter Drier —

The

When removing a filter drier, use a tubing cutter to cut the drier from the system. Do not unsweat a filter drier from the system. Heat from unsweating will release moisture and contaminants from drier into system.

Field Refrigerant Access Ports —

Field service access to refrigerant pressures is through the access ports located at the service valves (see Figs 34 and 38). These ports are

Factory High-Flow Access Ports —

There are two additional access ports in the system - on the suction tube between the compressor and the suction service valve and on the liquid tube near the liquid service valve (see Figs 35 and 39). These are brass fittings with black plastic caps. The hose connection fittings are standard

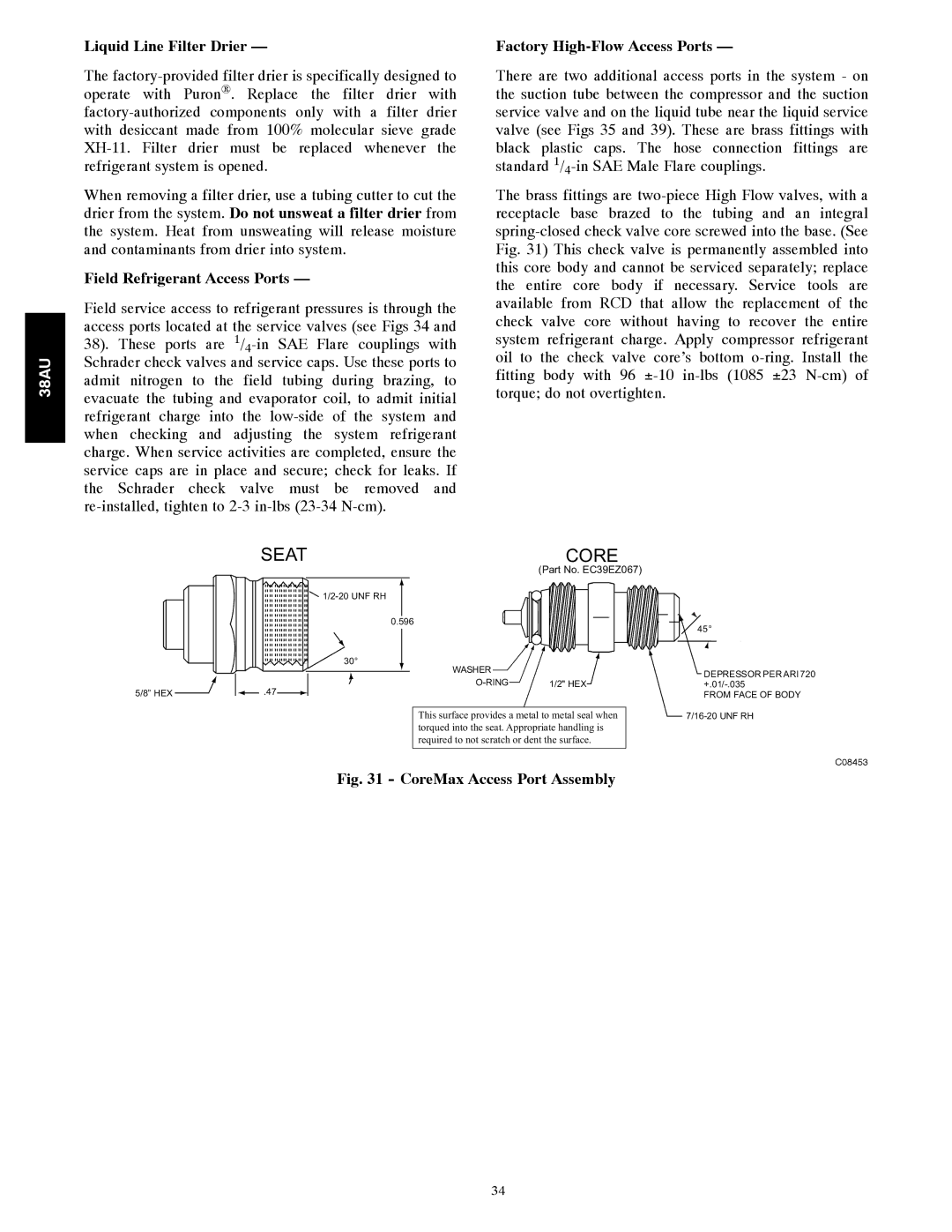

The brass fittings are

5/8” HEX![]()

SEAT | CORE | |||

|

| (Part No. EC39EZ067) | ||

|

|

|

|

|

![]()

0.596

30°

WASHER |

|

| 1/2" HEX |

![]() .47

.47![]()

This surface provides a metal to metal seal when torqued into the seat. Appropriate handling is required to not scratch or dent the surface.

Fig. 31 - CoreMax Access Port Assembly

45°

DEPRESSOR PER ARI 720

FROM FACE OF BODY

C08453

34