38AU

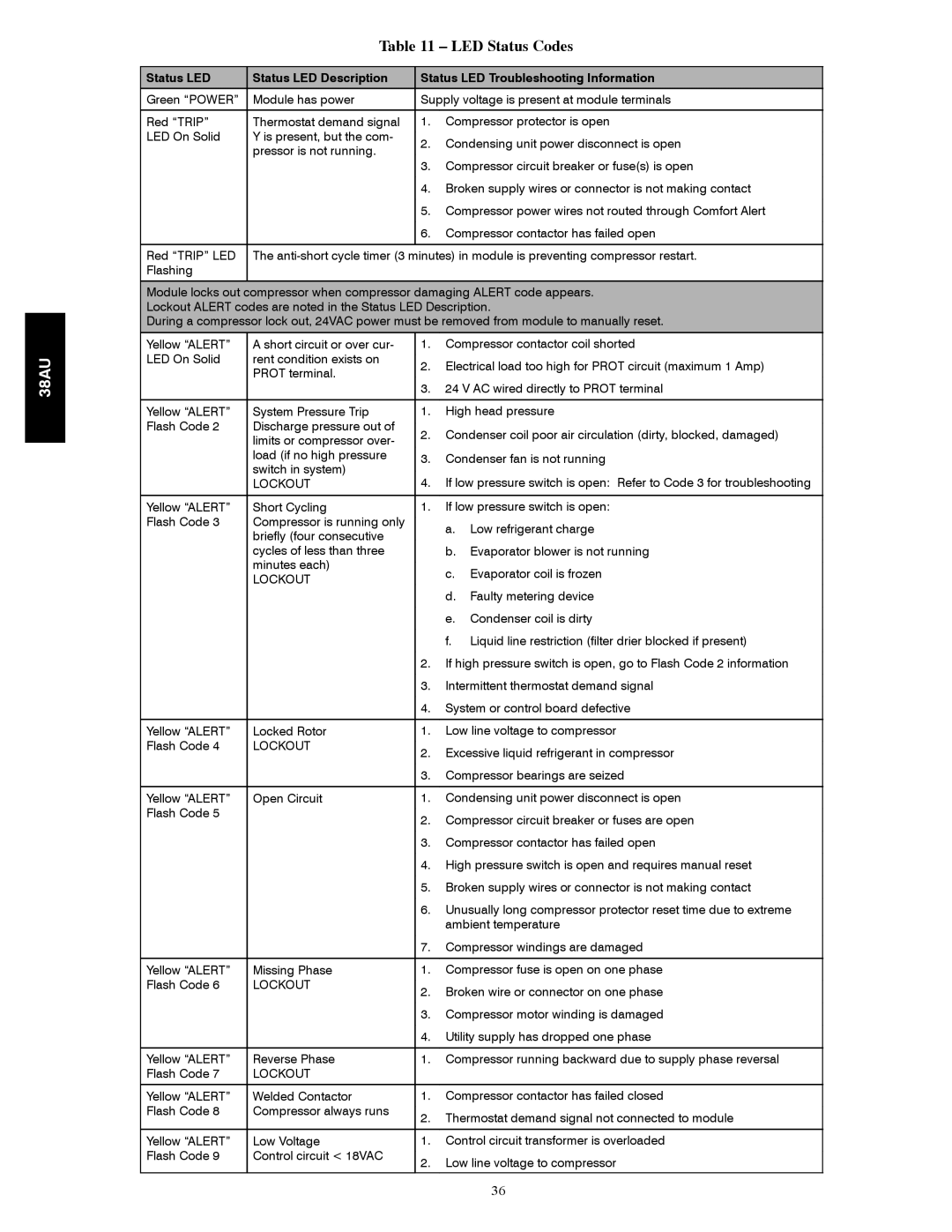

Table 11 – LED Status Codes

Status LED | Status LED Description | Status LED Troubleshooting Information | |

Green “POWER” | Module has power | Supply voltage is present at module terminals | |

|

|

|

|

Red “TRIP” | Thermostat demand signal | 1. | Compressor protector is open |

LED On Solid | Y is present, but the com- | 2. | Condensing unit power disconnect is open |

| pressor is not running. | ||

| 3. | Compressor circuit breaker or fuse(s) is open | |

|

| ||

|

| 4. | Broken supply wires or connector is not making contact |

|

| 5. | Compressor power wires not routed through Comfort Alert |

|

| 6. | Compressor contactor has failed open |

|

|

| |

Red “TRIP” LED | The | ||

Flashing |

|

|

|

|

|

|

|

Module locks out compressor when compressor damaging ALERT code appears. Lockout ALERT codes are noted in the Status LED Description.

During a compressor lock out, 24VAC power must be removed from module to manually reset.

Yellow “ALERT” | A short circuit or over cur- | 1. | Compressor contactor coil shorted | |

LED On Solid | rent condition exists on | 2. | Electrical load too high for PROT circuit (maximum 1 Amp) | |

| PROT terminal. | |||

| 3. | 24 V AC wired directly to PROT terminal | ||

|

| |||

|

|

|

| |

Yellow “ALERT” | System Pressure Trip | 1. | High head pressure | |

Flash Code 2 | Discharge pressure out of | 2. | Condenser coil poor air circulation (dirty, blocked, damaged) | |

| limits or compressor over- | |||

|

|

|

| |

| load (if no high pressure | 3. | Condenser fan is not running | |

| switch in system) | 4. | If low pressure switch is open: Refer to Code 3 for troubleshooting | |

| LOCKOUT | |||

|

|

|

| |

Yellow “ALERT” | Short Cycling | 1. | If low pressure switch is open: | |

Flash Code 3 | Compressor is running only |

| a. | Low refrigerant charge |

| briefly (four consecutive |

| ||

|

|

|

| |

| cycles of less than three |

| b. | Evaporator blower is not running |

| minutes each) |

| c. | Evaporator coil is frozen |

| LOCKOUT |

| ||

|

|

|

| |

|

|

| d. | Faulty metering device |

|

|

| e. Condenser coil is dirty | |

|

|

| f. | Liquid line restriction (filter drier blocked if present) |

|

| 2. | If high pressure switch is open, go to Flash Code 2 information | |

|

| 3. | Intermittent thermostat demand signal | |

|

| 4. | System or control board defective | |

|

|

|

| |

Yellow “ALERT” | Locked Rotor | 1. | Low line voltage to compressor | |

Flash Code 4 | LOCKOUT | 2. | Excessive liquid refrigerant in compressor | |

|

| |||

|

| 3. | Compressor bearings are seized | |

|

|

|

| |

Yellow “ALERT” | Open Circuit | 1. | Condensing unit power disconnect is open | |

Flash Code 5 |

| 2. | Compressor circuit breaker or fuses are open | |

|

| |||

|

| 3. | Compressor contactor has failed open | |

|

| 4. | High pressure switch is open and requires manual reset | |

|

| 5. | Broken supply wires or connector is not making contact | |

|

| 6. | Unusually long compressor protector reset time due to extreme | |

|

|

| ambient temperature | |

|

| 7. | Compressor windings are damaged | |

|

|

|

| |

Yellow “ALERT” | Missing Phase | 1. | Compressor fuse is open on one phase | |

Flash Code 6 | LOCKOUT | 2. | Broken wire or connector on one phase | |

|

| |||

|

| 3. | Compressor motor winding is damaged | |

|

| 4. | Utility supply has dropped one phase | |

|

|

|

| |

Yellow “ALERT” | Reverse Phase | 1. | Compressor running backward due to supply phase reversal | |

Flash Code 7 | LOCKOUT |

|

|

|

|

|

|

| |

Yellow “ALERT” | Welded Contactor | 1. | Compressor contactor has failed closed | |

Flash Code 8 | Compressor always runs | 2. | Thermostat demand signal not connected to module | |

|

| |||

|

|

|

| |

Yellow “ALERT” | Low Voltage | 1. | Control circuit transformer is overloaded | |

Flash Code 9 | Control circuit < 18VAC | 2. | Low line voltage to compressor | |

|

| |||

|

|

|

|

|

36