38AU

7.Hold garden sprayer nozzle close to finned areas and apply cleaner with a vertical,

8.Ensure cleaner thoroughly penetrates deep into finned areas.

9.Interior and exterior finned areas must be thoroughly cleaned.

10.Finned surfaces should remain wet with cleaning solution for 10 minutes.

11.Ensure surfaces are not allowed to dry before rinsing. Reapply cleaner as needed to ensure

12.Thoroughly rinse all surfaces with low velocity clean water using downward rinsing motion of water spray nozzle. Protect fins from damage from the spray nozzle.

13.Replace top cover and rear corner posts.

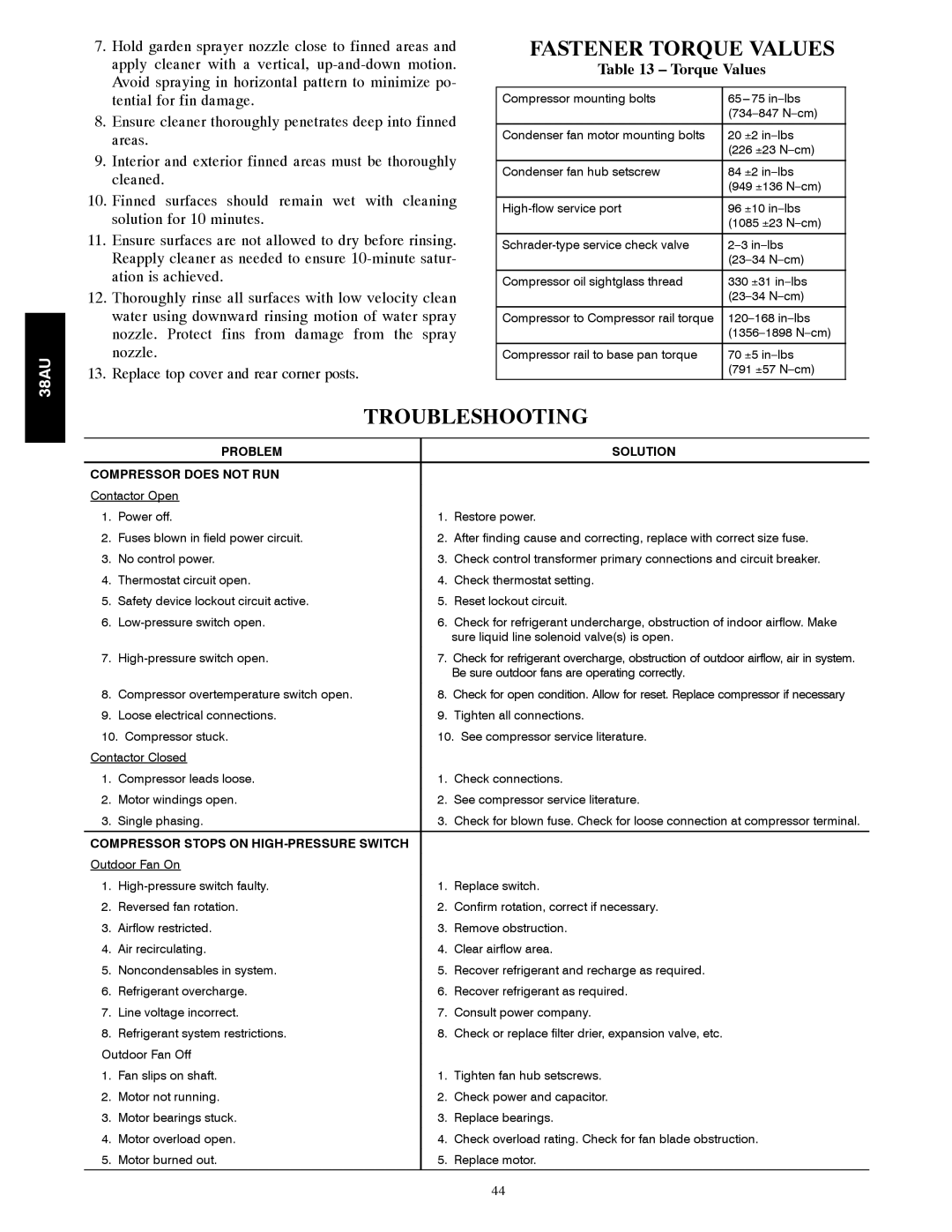

FASTENER TORQUE VALUES

Table 13 – Torque Values

Compressor mounting bolts | |

| |

|

|

Condenser fan motor mounting bolts | 20 ±2 |

| (226 ±23 |

|

|

Condenser fan hub setscrew | 84 ±2 |

| (949 ±136 |

|

|

96 ±10 | |

| (1085 ±23 |

|

|

| |

|

|

Compressor oil sightglass thread | 330 ±31 |

| |

|

|

Compressor to Compressor rail torque | |

| |

|

|

Compressor rail to base pan torque | 70 ±5 |

| (791 ±57 |

|

|

TROUBLESHOOTING

| PROBLEM |

| SOLUTION |

|

|

| |

COMPRESSOR DOES NOT RUN |

|

| |

Contactor Open |

|

| |

1. | Power off. | 1. | Restore power. |

2. | Fuses blown in field power circuit. | 2. | After finding cause and correcting, replace with correct size fuse. |

3. | No control power. | 3. | Check control transformer primary connections and circuit breaker. |

4. | Thermostat circuit open. | 4. | Check thermostat setting. |

5. | Safety device lockout circuit active. | 5. | Reset lockout circuit. |

6. | 6. | Check for refrigerant undercharge, obstruction of indoor airflow. Make | |

|

|

| sure liquid line solenoid valve(s) is open. |

7. | 7. | Check for refrigerant overcharge, obstruction of outdoor airflow, air in system. | |

|

|

| Be sure outdoor fans are operating correctly. |

8. | Compressor overtemperature switch open. | 8. Check for open condition. Allow for reset. Replace compressor if necessary | |

9. | Loose electrical connections. | 9. | Tighten all connections. |

10. Compressor stuck. | 10. See compressor service literature. | ||

Contactor Closed |

|

| |

1. | Compressor leads loose. | 1. | Check connections. |

2. | Motor windings open. | 2. | See compressor service literature. |

3. | Single phasing. | 3. | Check for blown fuse. Check for loose connection at compressor terminal. |

|

|

| |

COMPRESSOR STOPS ON |

|

| |

Outdoor Fan On |

|

| |

1. | 1. | Replace switch. | |

2. | Reversed fan rotation. | 2. | Confirm rotation, correct if necessary. |

3. | Airflow restricted. | 3. | Remove obstruction. |

4. | Air recirculating. | 4. | Clear airflow area. |

5. | Noncondensables in system. | 5. | Recover refrigerant and recharge as required. |

6. | Refrigerant overcharge. | 6. | Recover refrigerant as required. |

7. | Line voltage incorrect. | 7. | Consult power company. |

8. | Refrigerant system restrictions. | 8. | Check or replace filter drier, expansion valve, etc. |

Outdoor Fan Off |

|

| |

1. | Fan slips on shaft. | 1. | Tighten fan hub setscrews. |

2. | Motor not running. | 2. | Check power and capacitor. |

3. | Motor bearings stuck. | 3. | Replace bearings. |

4. | Motor overload open. | 4. | Check overload rating. Check for fan blade obstruction. |

5. | Motor burned out. | 5. | Replace motor. |

|

|

|

|

44