SCRAPWOOD | BLADEGUARD | FRAMINGSQUARE |

/

BLADENUT

MITERGAGEGROOVE | Fig. 35 |

|

WASHER

TOTIGHTEN |

|

BLADENUT | Fig. 34 |

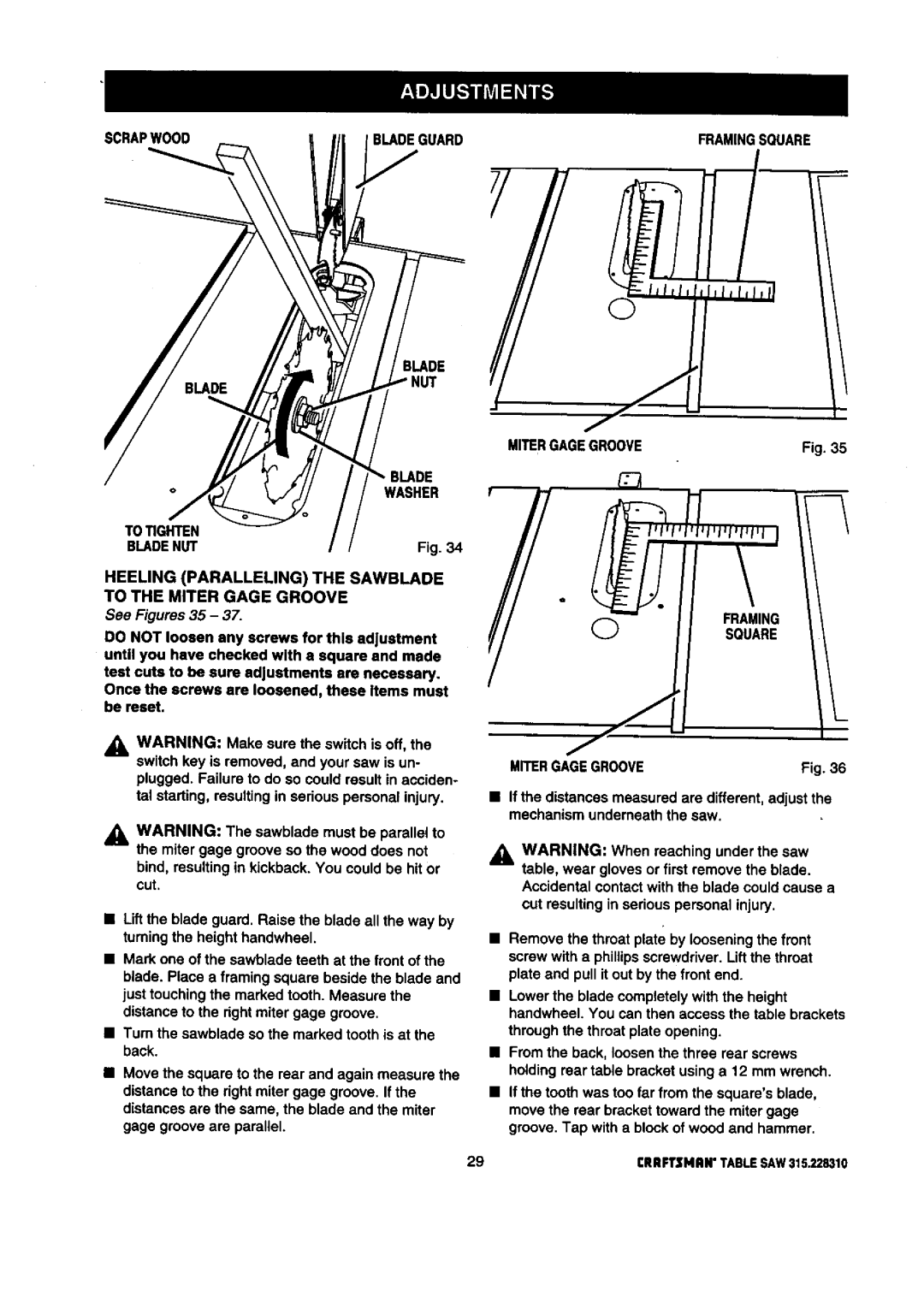

HEELING (PARALLELING) THE SAWBLADE TO THE MITER GAGE GROOVE

See Figures 35 - 37.

DO NOT loosen any screws for this adjustment until you have checked with a square and made test cuts to be sure adjustments are necessary.

Once the screws are loosened, these Items must be reset.

_k WARNING: Make sure the switch is off, the switch key is removed, and your saw is un- plugged. Failure to do so could result in acciden-

tal starting, resultingin serious personal injury.

_l, WARNING: The sawblade must be parallel to the miter gage groove so the wood does not

bind, resulting in kickback.You could be hit or cut.

•Lift the blade guard. Raise the blade all the way by turning the height handwheel.

•Mark one of the sawblade teeth at the front of the blade. Place a framing square beside the blade and just touching the marked tooth. Measure the distance to the right miter gage groove.

•Turn the sawblade so the marked tooth is at the back.

•Move the square to the rear and again measure the

distanceto the right miter gage groove. If the distancesare the same, the blade and the miter gage groove are parallel.

(_FRAMING SQUARE

f

MITERGAGEGROOVE | Fig. 36 |

|

•If the distancesmeasured are different,adjust the mechanismunderneath the saw.

j_ WARNING: When reaching under the saw table, wear gloves or first remove the blade.

Accidentalcontact with the blade could cause a cut resultingin serious personal injury.

•Remove the throat plate by loosening the front screw with a phillips screwdriver.Lift the throat plate and pull it out by the front end.

•Lowerthe blade completelywith the height handwheel. You can then access the table brackets

through the throat plate opening.

•From the back, loosen the three rear screws holdingrear table bracket using a 12 mm wrench.

•If the toothwas too far from the square'sblade,

move the rear bracket toward the miter gage groove.Tap with a block of wood and hammer.