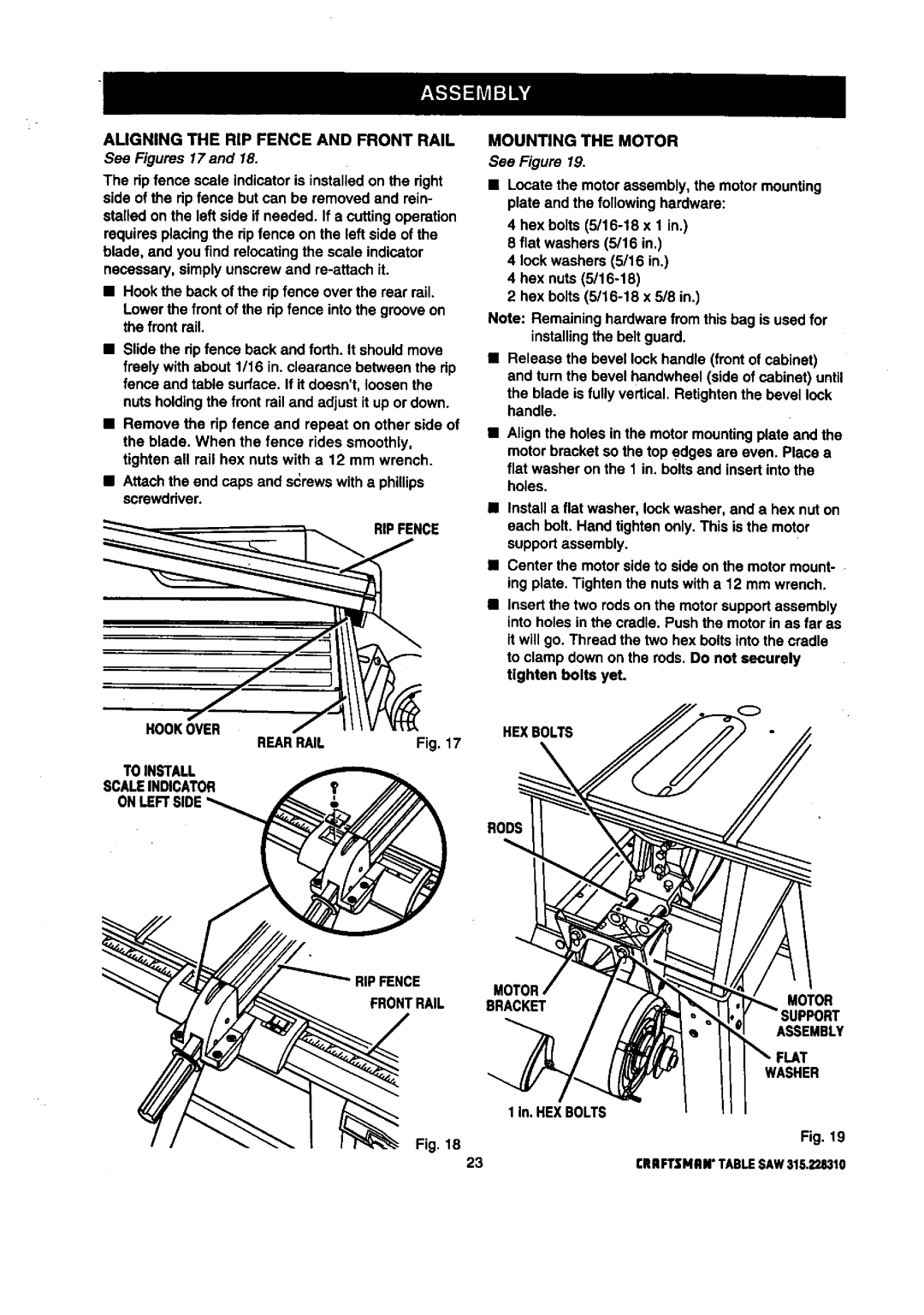

ALIGNINGTHERIPFENCEANDFRONTRAIL

See Figures 17and 18.

The ripfence scale indicatoris installedon the right side of the rip fence but can be removed and rein-

stalled on the left side if needed. If a cutting operation requiresplacing the rip fence on the left side of the blade, and you find relocatingthe scale indicator necessary, simply unscrewand

•Hook the back of the rip fence over the rear rail. Lower the frontof the rip fence into the groove on the front rail.

•Slide the rip fence back and forth. It should move freely with about 1/16 in. clearance between the rip fence and table surface. If it doesn't,loosen the nuts holdingthe front rail and adjust it up or down.

•Remove the rip fence and repeat on other side of the blade. When the fence rides smoothly, tighten all rail hex nuts with a 12 mm wrench.

•Attach the end caps and s_rews with a phillips screwdriver.

NCE

oo

REARRAIL | Fig. 17 |

TOINSTALL

SCALEINDICATOR

ONLEFT

RIPFENCE

FRONTRAIL

MOUNTING THE MOTOR

See Figure 19.

•Locate the motorassembly, the motor mounting plate and the followinghardware:

4 hex bolts

8 flat washers (5/16 in,)

4 lock washers (5/16 in.)

4 hex nuts

2 hex

Note: Remaining hardware from this bag is used for installingthe belt guard.

•Release the bevel lock handle (frontof cabinet) and turn the bevel handwheel (side of cabinet) until

the blade is fullyvertical. Retightenthe bevel lock handle.

•Align the holes in the motormountingplate and the motor bracket so the top edges are even. Place a flat washer on the 1 in. boltsand insert into the holes.

•Install a flat washer, lock washer, and a hex nut on each belt. Hand tighten only. This is the motor supportassembly.

•Center the motorside to side on the motor mount- ing plate. Tighten the nuts with a 12 mm wrench.

•Insert the two rodson the motor supportassembly into holes in the cradle. Push the motor in as far as

it will go. Thread the two hex bolts intothe cradle to clamp down on the rods. Do not securely tighten bolts yet.

HEX BOLTS

RODS

MOTOR

BRACKETMOTOR

ASSEMBLY

WASHER

1 In.HEXBOLTS

Fig. 18 | Fig. 19 |

23 | CRRFTSNRN"TABLESAW315.228310 |