Toothed safety devices behind the blade designed to stop a workpiece from being kicked back at the operator during a rippingoperation.

Arbor

The shaft on which a blade or cutting tool is mounted. Bevel Cut

Acutting operation made with the blade at any angle other than 90" to the saw table.

Compound Cut

A cut with both a miter angle and a bevel angle.

Crosscut

Acuttingoperation made across the grain or the width of the workpiece.

Dsdo

A

Featherboard

A device to help guide workpieces during ripcuts.

Freehand (for table saw)

Dangerous practice of making s cut without using dp or miter fences. See Safety Rules.

Gum

A sticky,

Alignment of the blade. Kerf

The material removed by the blade in a through cut or the slot produced by the blade in a

Kickback

A hazard that can occur when blade binds or stalls, throwingworkpiece back toward operator.

Leading End

The end of the workpiece pushed into the cutting tool first.

Miter Cut

Acutting operation made with the miter gage at any angle other than 0".

Molding

A

Push Stick

A device used to feed the workpiece throughthe saw blade during narrowcutting operations. It helps keep the operator'shands well away from the blade,

Rabbet

A notch in the edge of a workpiece.

Resaw

Acuttingoperation to reduce the thicknessof the workpiece in order to make thinner pieces.

Resin

A

RIp Cut

A cut made with the the grain of the workpiece.

Sswblade Path

The area directly in line with the blade

Set

The distancethat the tip of the saw blade tooth is bent (or set) outwardfrom the face of the blade.

Saw throwingback a workpiece;similar to kickback,

Through Sawing

Any cutting operationwhere the blade extends completely throughthe workpiece.

Trailing End

The workpiece end last cut by the blade in a dp cut.

Workpece

The item on whichthe cutting operation is being done.

The surfacesof a workpiece are commonly referred to as faces, ends, and edges.

Worktable

The surface on which the wodq_ece rests while performinga cutting operation.

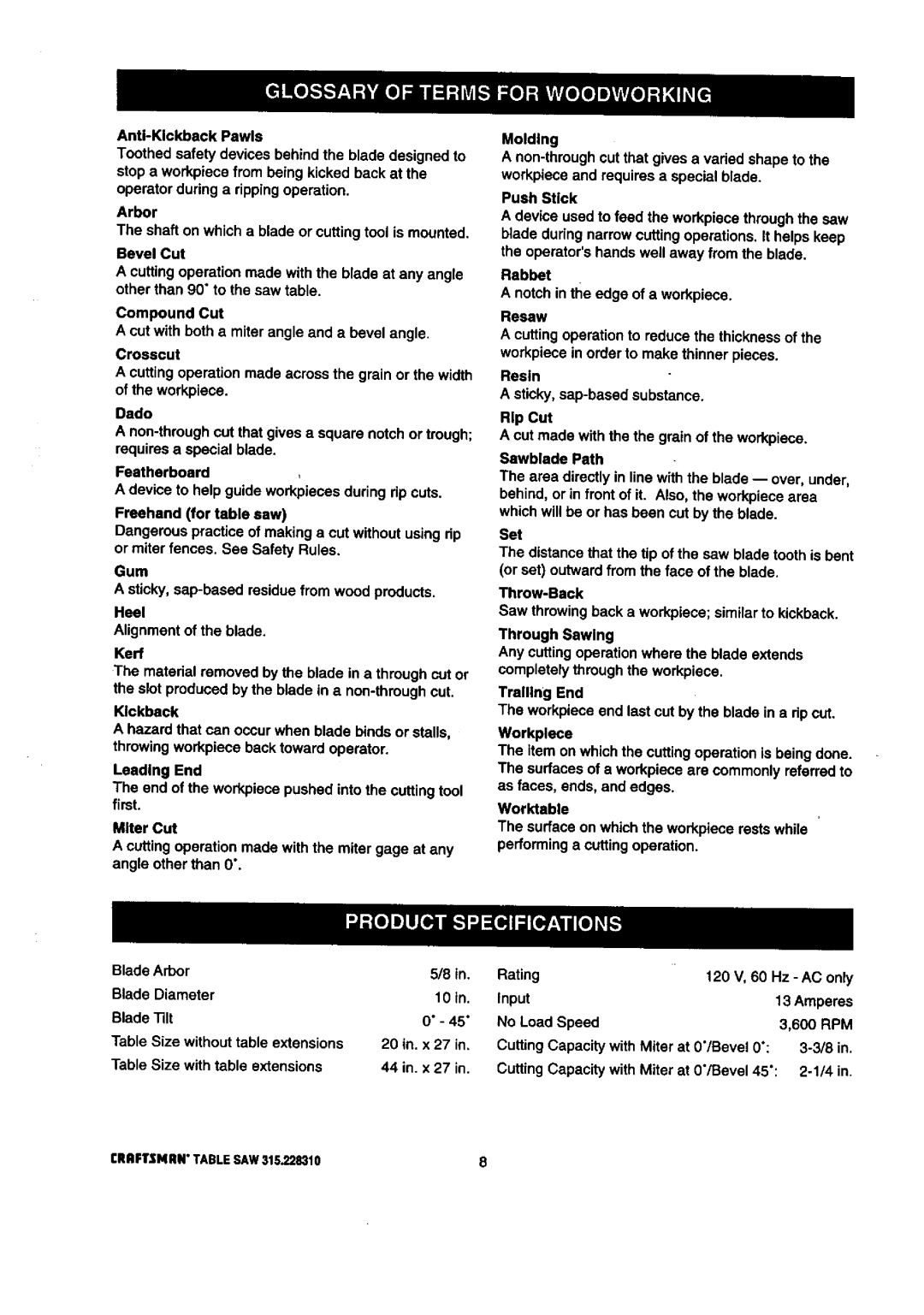

Blade Arbor | 5/8 in. | |

Blade Diameter | 10 in. | |

Blade Tilt | 0" - 45" | |

Table Size without table extensions | 20 in. x 27 | in. |

Table Size with table extensions | 44 in. x 27 | in. |

Rating | 120 V, 60 Hz - AC only | |

Input | 13 Amperes | |

No Load Speed |

| 3,600 RPM |

Cutting Capacity with Miter at 0"/Bevel 0": | ||

Cutting Capacity with Miter at O'/Bevel45": | ||

rRRFTSNlUI" TABLESAW$1G,228310 | 8 |