Assembly is best done in the area where the saw will be used. When you remove the table saw base, loose parts, and hardware from the packing matedals, check all items with the loose parts listand drawing. If you are

unsure about the descriptionof any part, refer to the drawing. If any parts are missing, delay assemblinguntil you have obtained the missingpart(s).

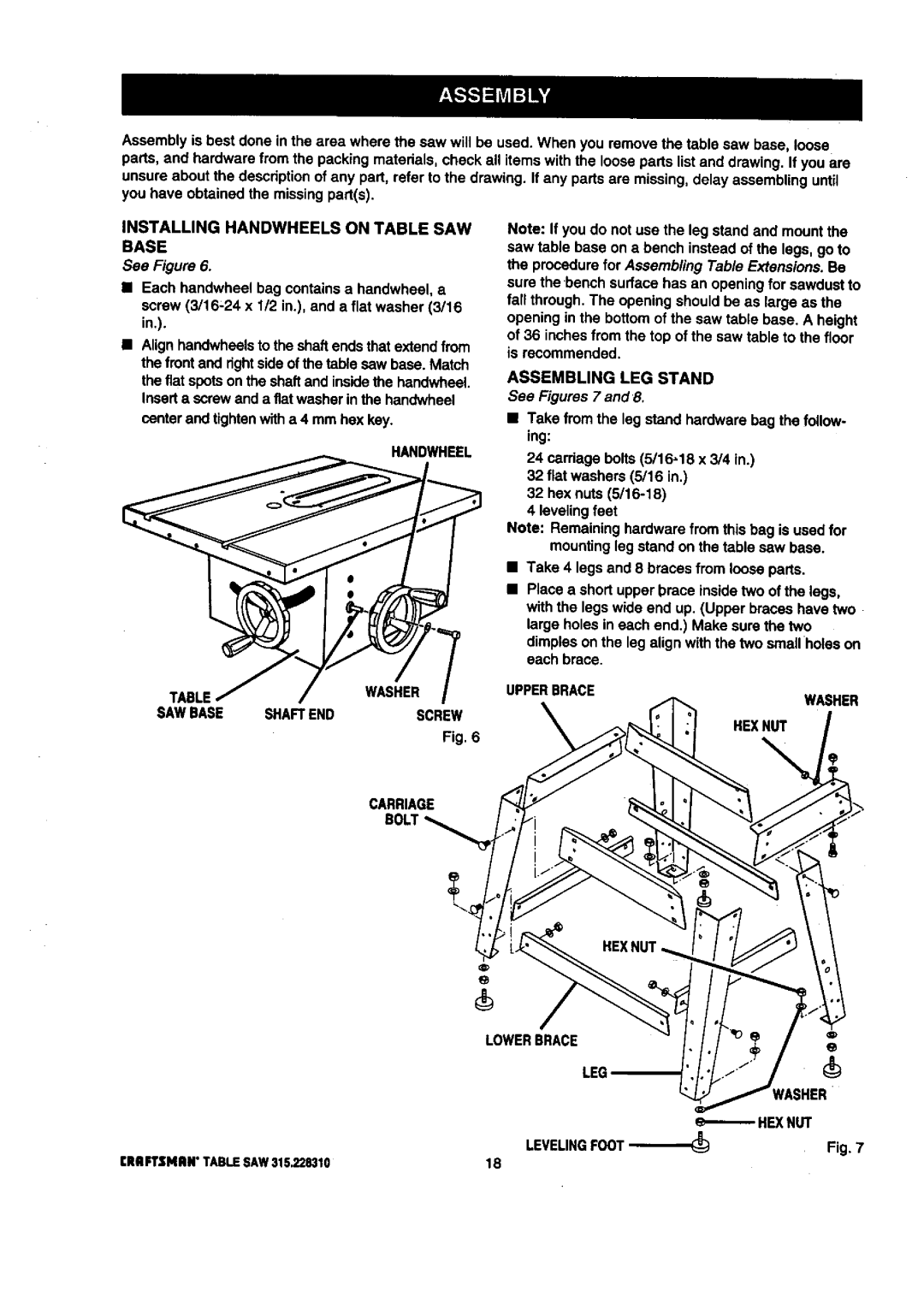

INSTALLING HANDWHEELS ON TABLE SAW BASE

See Figure 6.

•Each handwheel bag contains a handwheel, a screw

•Alignhandwheelsto the shaftends that extendfrom

the frontand rightside of the table saw base. Match the fiat spotson the shaftand insidethe handwheeL Inserta screwand a fiatwasher in the handwheel

center and tightenwitha 4 mm hex key.

HANDWHEEL

Note: If you do not usa the leg stand and mount the

saw table base on a bench instead of the legs, go to the procedurefor Assembling Table Extensions. Be

sure the 'benchsurface has an opening for sawdust to fall through.The opening shouldbe as large as the

opening in the bottomof the saw table base, A height of 36 inchesfrom the top of the saw table to the floor is recommended.

ASSEMBLING LEG STAND

See Figures 7 and 8.

•Take from the leg stand hardware bag the follow- ing:

24carriage bolts (5/16,18 x 3/4 in.)

32flat washers (5/16 in.)

32hex nuts

4levelingfeet

Note: Remaining hardware from this bag is used for mountingleg stand on the table saw base.

•Take 4 legs and 8 braces from loose parts.

•Place a shortupper brace insidetwo of the legs, with the legs wide end up. (Upper braces have two large holes in each end.) Make sure the two

dimples on the leg align with the two small holes on each brace.

TABLE |

| WASHER | UPPERBRACE |

| WASHER | ||

SAWBASE | SHAFTEND | SCREW | HEXNUT |

|

| Fig. 6 | |

|

| % | |

|

|

| |

|

| CARRIAGE |

|

LOWERBRACE

LEG

HEXNUT

LEVELINGFOOT_ | Fig. 7 |

[RRFTSMIIN" TABLESAW315,228310 | 18 |