System Configuration Manual

Raptor

Page

Version

Page

Table of Contents

Table of Contents

Device Handling Service Functions

Menu Guide

TOC-4

Manual Overview

Service Functions

Technical Documentation

Menu Guide

Raptor System Overview

Raptor system architecture

Rosemount 2410 Tank Hub

TankMaster HMI Software

Rosemount 2160 Field Communication Unit

Rosemount 5900S Radar Level Gauge

Rosemount 5300 Guided Wave Radar

Rosemount 2240S Multi-Input Temperature Transmitter

Rosemount 644 Temperature Transmitter

Rosemount 5400 Radar Level Transmitter

What is TANKMASTER?

Key Features

Tankmaster Software Package

OPC Server with Browser Customized views

Installing the Tankmaster Software

Installed Software Modules

System Requirements

Installation Procedure

Installation Options

Device installation

Installing a Tank Level Gauging System Illegal Characters

Tank installation

Wizards

WinSetup Main Window

WinSetup workspace

Service , Tools , and Help

Menus

WinSetup Toolbar

Toolbar

Status BAR

Deselect the Status bar option

Workspace Viewing Tanks and Devices

Workspace

Icons

User Access Level Username Password

User Management

Logging On to TankMaster

To Administrate User Accounts

From the ToolsAdministrative Tools menu choose User Manager

New user account is added

To Set Required Access Levels

Add Program see Customizing the Tools Menu in WinSetup on

To Change Protection Level of Separate Windows

Choose the Protection Level... option

To Change Password

To Change Inactivity Timeout

Installing a Raptor Level Gauging System

Communication Protocol Setup

System Configuration Overview

Preparations Installation Procedure

Preferences

Raptor system installation procedure

Installation and Configuration of Rosemount 2410 Tank Hub

Installation and Configuration of Field Devices

Calibration

Using the Device Installation Wizard

Device

Communication Protocol Setup

Slave Protocol

Master Protocol Channel Configuration

Port

Modbus Master channel 1 is enabled

Slave Protocol Channel Configuration

TRL2 Modbus Communication Setup

Stop bits

Advanced Configuration

Tank mapping configuration

Protocols Protocol subfolder

Protocol Server Configuration

Preferences

Measurement Units

Ambient Air Temperature

Inventory

Miscellaneous

Server Preferences window select the Miscellaneous tab

Setting the Name Tag Prefixes

System Configuration Manual

System Configuration Manual

Select the Enable Tank Visibility function check box

Tank Visibility

Visible Hidden

Field Device Installation Overview

Configuration

Installing a Rosemount 2160 FCU

System Configuration Manual

How to change the Modbus address of the FCU

Fieldbus communication with a

Select Slave Type=2410

Level Gauge Modbus Address 2410 Level

See Examples of 2160 FCU Slave Database Configuration on

2160 Slave Database and the 2410 Tank Database

ATD Device Modbus Address 2410 Temp

Summary of FCU Slave Database entry fields

Examples of 2160 FCU Slave Database Configuration

Example 1 single tank connected to one 2410 Tank Hub

Tank Database TK-1 FCU Slave Database Tank Database TK-2

System Configuration Manual

Example 2 several Tanks connected to one 2410 Tank Hub

ATD 2230, 2240S Tank Hub

Tank Database FCU Slave Database

Summary of 2160 Installation and Configuration

Installing a Rosemount 2410 Tank HUB

Installation Wizard

Device Type

Communication Setup

How to change the Modbus address

Tank Database Setup

System Configuration Manual

Device Tag Setup

Local Display Setup

Variable Description

System Configuration Manual

Configuration Summary

Devices appear in the WinSetup workspace window

Tank Hub Configuration window

Summary of Tank Hub Installation and Configuration

System Configuration Manual

Installing a Rosemount 5900S Radar Level Gauge

Configuration via the Properties Window

5900S RLG Properties window appears

This field shows the tank position in the 2410 Tank Database

System Configuration Manual

5900S with Parabolic Antenna

To configure a User Defined antenna advanced

5900S with Horn Antenna

5900S with Still-pipe Array Antenna

5900S RLG Properties window select the Geometry tab

Tank Reference Height R

Reference Distance G

Minimum Level Distance C

Enter the Calibration Distance

Installing a 5900S Using the Installation Wizard

Configure the Tank Database in the 2410 Tank Hub Properties

Using the installation wizard

System Configuration Manual

System Configuration Manual

Advanced Configuration

Tank Shape

5900S RLG Properties window select the Tank Shape tab

Tank Environment

5900S RLG Properties window select the Environment tab

Advanced Configuration Tab

Properties/Advanced Configuration window

Rosemount 5900S Reference Manual Document no EN

Installing Auxiliary Tank Devices

Opening the Properties Window

System Configuration Manual

Communication Parameter Setup

Temperature Sensor Configuration

22xx ATD window select the 2240S MTT Temperature Sensor tab

System Configuration Manual

Average Temperature Calculation

System Configuration Manual

Auxiliary Sensor Configuration

Water Level Sensor

22xx ATD window, select the 2240S MTT Auxiliary Sensor tab

System Configuration Manual

Advanced Parameter Source Configuration

Configuration Temperature Transmitters

7 2230 Graphical Field Display

22xx ATD window, select the 2230 Graphical Field Display tab

System Configuration Manual

Installing a Rosemount

Configuration via 5400 Properties

System Configuration Manual

Free Propagation

Still-pipes

Tank Reference Height R

See the Rosemount 5400 Reference Manual

Installing a 5400 Using the Installation Wizard

Using the installation wizard

System Configuration Manual

System Configuration Manual

Advanced Configuration

See the Rosemount 5400 Reference Manual Document No

Installing a Rosemount

Configuration via 5300 Properties

5300 GWR window appears

System Configuration Manual

System Configuration Manual

See the Rosemount 5300 Reference Manual

Installing a 5300 Using the Installation Wizard

Using the installation wizard

System Configuration Manual

System Configuration Manual

Measurement Mode

Rapid Level Change

Dielectric Constant/Dielectric Range

100

Installing a Tank 5.11.1 Overview

Starting the Tank Installation Wizard

See also Installing a New Tank on

Installing a New Tank

300510EN, Rev AA December Assign devices to the current tank

Show 2160 FCU Slave Positions Advanced

Select the Advanced Parameter Source Configuration tab

22XX ATD/PARAMETER Source Window Tank Configuration Window

108

109

Summary

Tank Type

Summary of Tank Installation and Configuration

Tank Configuration

Select Devices

To Change Tank Configuration

To Uninstall a Tank

Adding a Tank to a Raptor System

12. a new tank and 2410 Tank Hub are added to the workspace

Adding a New Tank and a New 2410 Tank Hub

116

Adding a New Tank to an Existing 2410 Tank Hub

Open the 2160 FCU Properties window

300510EN, Rev AA December Select the Tank Database tab

Tank position 4 is added

120

121

Manual Adjustment

Level Gauge Calibration

Using the Calibrate Function

To calibrate a Rosemount 5900S Rada Level Gauge

Tank Capacity

Tank Entry

Setting UP a Hybrid System

127

128

129

130

131

Check that Value Source is set to Automatic

To Change Device Configuration

Device Handling

Device Handling

To Uninstall a Device

To uninstall a device

To uninstall a device without uninstalling the tank

Click the Change button

Open the Tanks folder

300510EN, Rev AA December Device Handling

System Status

Saving and Loading Database Registers

Customizing the Tools Menu in Winsetup

Browse button Command

User Defined Temperature Conversion

Disable Use Auto Sensor Configuration

Click the Configure User Defined Linearization Table button

User Defined Linearization Table

Click the Configure User Defined Formula button

User Defined Formula

Click the Configure User Defined Individual Formula button

User Defined Individual Formula

Viewing Input and Holding Registers

To Edit Holding Registers

System Configuration Manual

View Diagnostic Registers

Configure Button

Restore to Default Setting

Device Configuration file

Start the TankMaster WinSetup program

Logging Measurement Data

Saving and Loading Database Registers

To Save Device Registers Single Device

To Save Device Registers Multiple Devices

To Recover a Device Database

Upgrading the Device Software

System Configuration Manual

Tank Scan

System Configuration Manual

Graph Area

General Amplitude Threshold is shown

General Amplitude Threshold will be

Points

Gauge Reference Point is shown as a

Previous Peaks

File Storage

To save Tank Scan data displayed in the Graph Area

To export tank scan data to an external file

Select the Export tank scan data to external file check box

System Configuration Manual

To load data from a saved file into the Graph Area

To delete a saved file

Action Buttons

Editing

To add a False Echo Area or an Amplitude Threshold Point

To delete a False Echo Area or Amplitude Threshold Point

Viewing Tank Data

Viewing Data from All Tanks

Viewing Data From a Single Tank

Viewing Alarm Status

System Configuration Manual

Protocol Handling

Logging the Channel Communication

System Configuration Manual

Saving the Communication Log to File

Set the Log Schedule

FC2

Searching for Connected Devices

Channel Statistics

Tankmaster Administrator

Log on

Changing the Administrator Program password

Open the TankMaster Administrator window

Autostart

Backup

System Configuration Manual

Restore

System Configuration Manual

System Configuration Manual

System Configuration Manual

File Version Information

Processes

300510EN, Rev AA December Service Functions

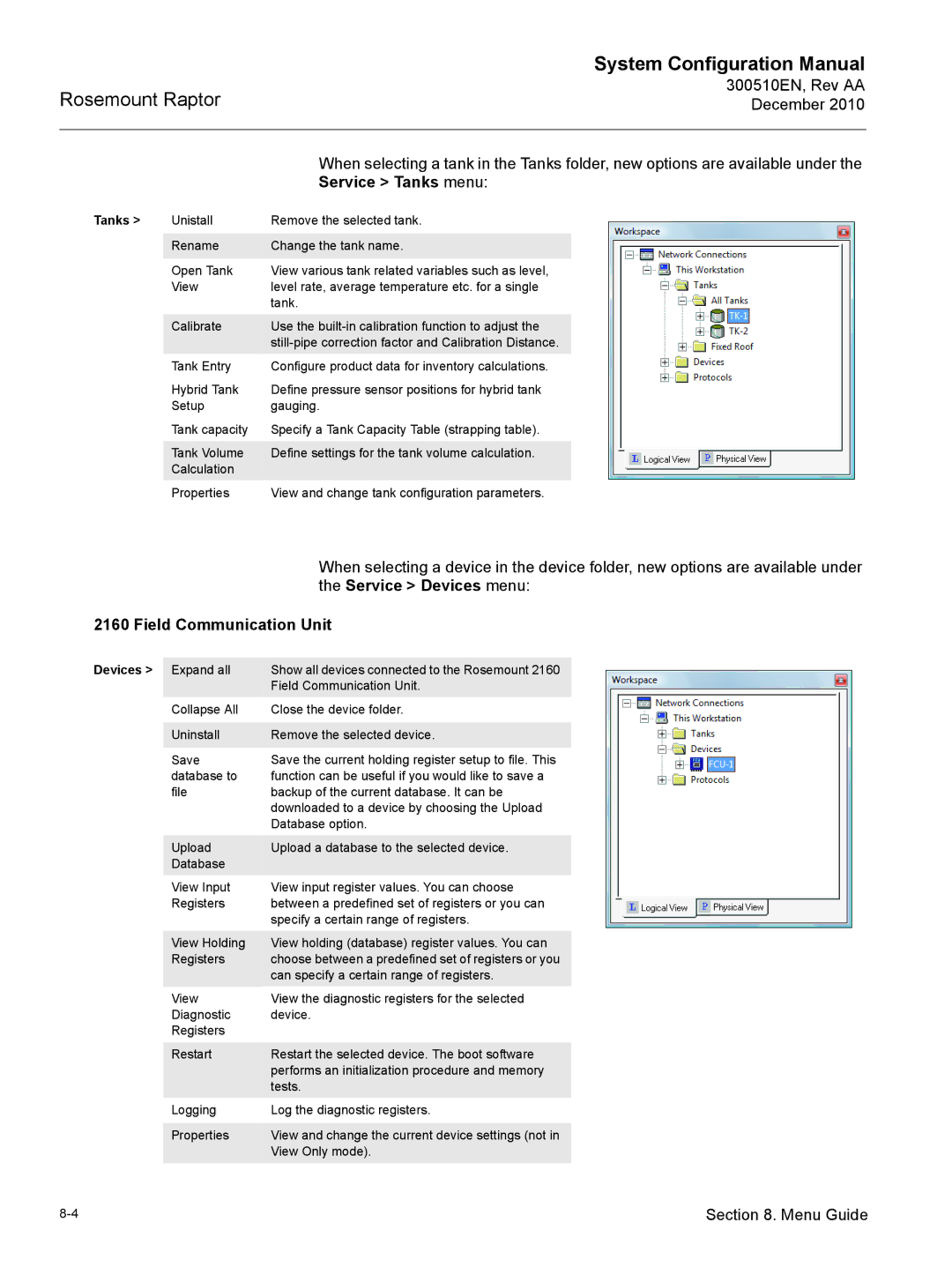

Section Menu Guide

File

View

Service

Servers Rename

Service Tanks menu

Field Communication Unit

Tank Hub

5900S Radar Level Gauge

Auxiliary Tank Devices ATDs 2240S, 2230 etc

Protocols

Preferences

Tools

Help

300510EN, Rev AA December Menu Guide

Index

Numerics

300510EN, Rev AA

Index-3

Index-4

Page

300510EN, Rev. AA December